Method for improving detection efficiency and representativeness of chemical components of crude tobacco package

A technology of detection efficiency and chemical composition, applied in the direction of material analysis, measuring devices, scientific instruments, etc. through optical means, can solve the problems of non-representation, heavy processing workload, large differences, etc., and improve the reliability expression , increase utilization, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

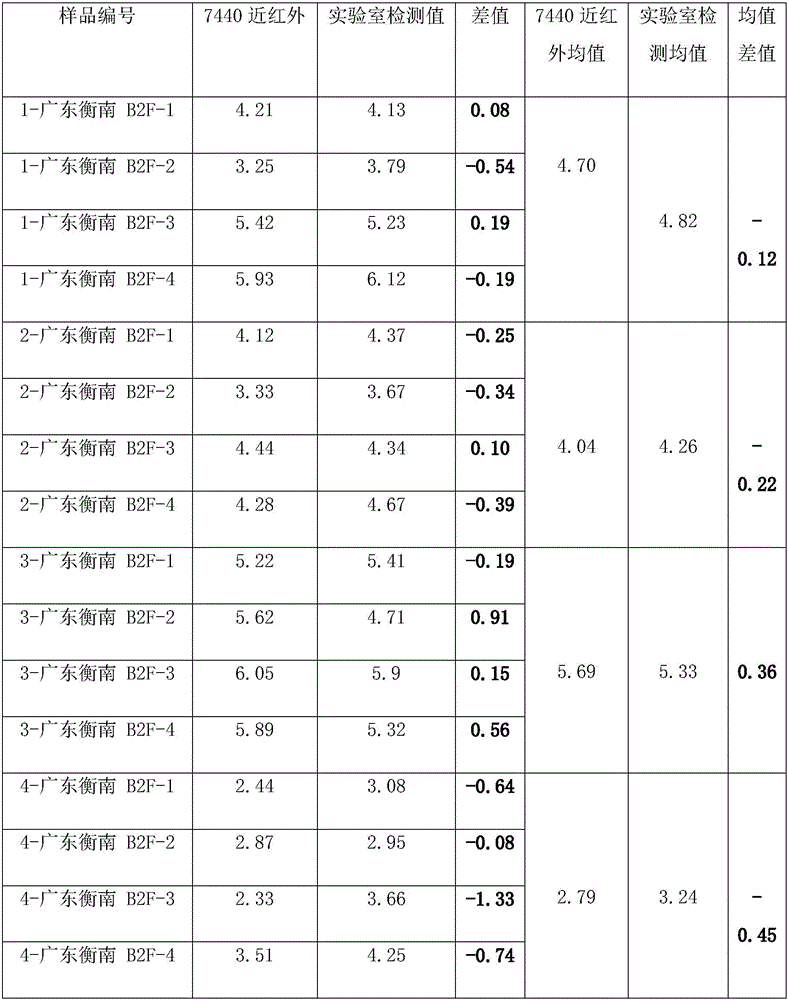

[0049] S1: Take four times of multi-point sampling on the four corners of the original cigarette pack of No. 1 cigarettes and sample 3 tobacco leaves each time, and mix the obtained tobacco leaves for a total of 12 pieces for inspection;

[0050] S2: Lay the tobacco leaves obtained in s1 on the detection conveyor belt, start the detection conveyor belt, and the tobacco leaves are conveyed by the detection conveyor belt for 60s through the spot irradiation detection area of the online near infrared spectrometer, and the detection value is recorded;

[0051] S3: Perform numerical averaging optimization processing on the numerical value obtained in S2 to obtain the chemical composition value of the entire pack of the original cigarette pack. See the table below:

[0052] Sample serial number 7440 near infrared (%) Laboratory test value (%) deviation(%) number 14.214.330.12

Embodiment 2

[0054] S1: Take five multi-point sampling of the four corners of the original cigarette pack and the tobacco leaves in the middle of the pack of No. 1 original cigarettes, and sample 2 tobacco leaves each time, and mix together 15 pieces of tobacco leaves to be inspected;

[0055] S2: Lay the tobacco leaves obtained in s1 on the detection conveyor belt, start the detection conveyor belt, and the tobacco leaves are conveyed by the detection conveyor belt for 20s through the light spot of the online near-infrared spectrometer to illuminate the detection area, and the detection value is recorded;

[0056] S3: Perform numerical averaging optimization processing on the numerical value obtained in S2 to obtain the chemical composition value of the entire pack of the original cigarette pack. See the table below:

[0057] Sample serial number 7440 near infrared (%) Laboratory test value (%) deviation(%) number 14.264.330.07

Embodiment 3

[0059] S1: Perform the S-type sampling method on the original cigarette pack of No. 1 tested and sample 15 tobacco leaves and mix them for inspection;

[0060] S2, spread the tobacco leaves obtained in s1 on the detection conveyor belt, and the tobacco leaves are conveyed by the detection conveyor belt for 120s through the spot of the online near infrared spectrometer to irradiate the detection area, and the detection value is recorded;

[0061] S3: Perform numerical averaging optimization processing on the numerical value obtained in S2 to obtain the chemical composition value of the entire pack of the original cigarette pack. See the table below:

[0062] Sample serial number 7440 near infrared (%) Laboratory test value (%) deviation(%) number 14.304.330.03

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com