Photovoltaic module hot spot defect detection method based on multi-scale feature map inference network

A multi-scale feature, photovoltaic module technology, applied in the field of defect detection, can solve problems such as poor detector robustness, achieve strong robustness, avoid inefficiency and uncertainty, and improve recognition capabilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

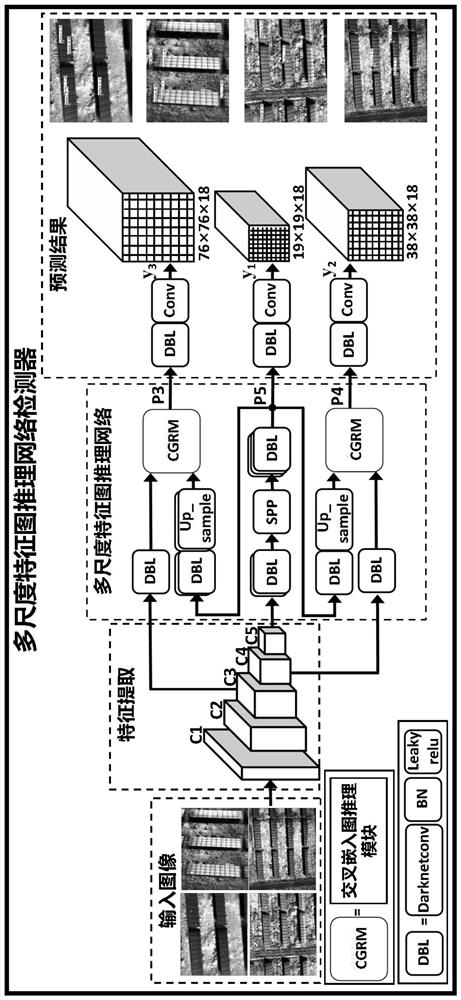

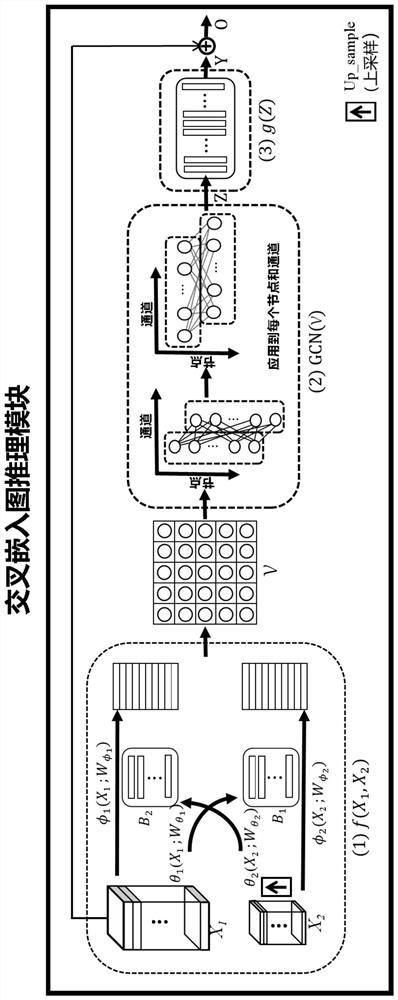

Method used

Image

Examples

Embodiment 1

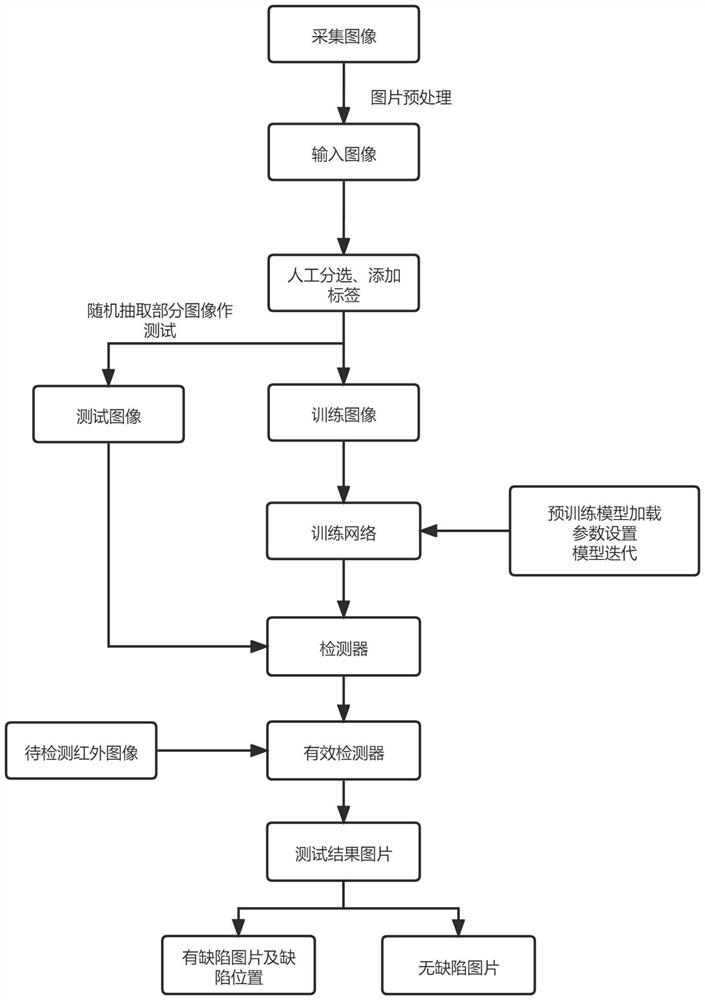

[0068] This embodiment provides a photovoltaic module hot spot defect detection method based on a multi-scale feature map reasoning network, which is characterized in that the specific steps of the method are:

[0069] The first step: the acquisition of data sets

[0070] 1.1 Original image acquisition: An infrared camera is mounted on the UAV, and the photo of the front of the photovoltaic module of the UAV at different flight heights is taken by the infrared camera; in this example, four heights of 28 meters, 35 meters, 47 meters and 60 meters were taken infrared image.

[0071] 1.2 Data set production: normalize the size of the photos obtained in step 1.1. The size of the infrared image in this example is 640×512, and 1,500 defect images are selected for each height to obtain a hot spot defect image library with a quantity of 6,000;

[0072] 1.3 Manually use LabelImg to mark the defect area of each image in the hot spot defect image database with the hot spot defect type...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com