Rotor heating device of modularized rotor experiment table

A rotor heating and modular technology, applied in electric heating devices, coil devices, induction heating and other directions, can solve the problems of long design cycle, waste of rotor test bench, high construction cost, and achieve low cost, convenient installation, safe and reliable installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

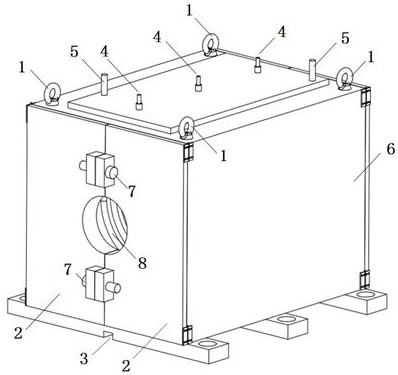

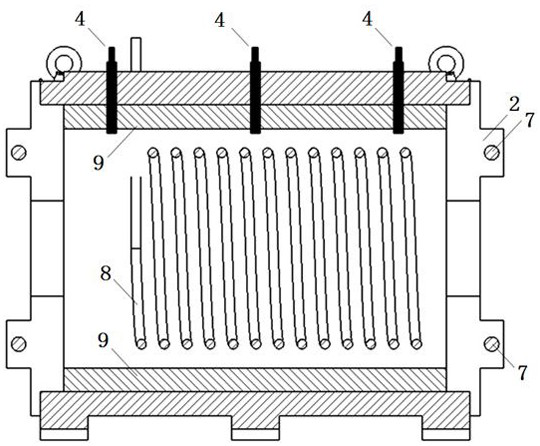

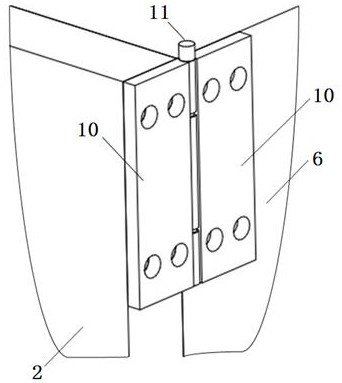

[0015] Referring to each figure, a rotor heating device of a modular rotor test bench, the rotor heating device includes an eyebolt 1, a modular end door 2, a temperature sensor 4, a terminal post 5, a box body 6, a door bolt 7, and a heating coil 8. Leaflets 10 and pins 11; the number of eye screws 1 is 4, and they are respectively installed on the 4 corners of the top of the box body 6; the heating coil 8 is arranged in the box body 6, and the two sides of the heating coil 8 The ends are respectively connected with two terminals 5 passing through the casing 6; the casing 6 is provided with an insulating layer 9, the temperature sensor 4 is arranged on the top of the casing 6, and the temperature sensor 4 passes through the casing 6 and Insulation layer 9; the number of the modular end doors 2 is 4, and they are respectively installed on the box body 6 through hinges 10 and pins 11, wherein the two modular end doors 2 on the same side are respectively equipped with door bolts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com