Fluid energy turbine machine

A technology of fluid energy and turbines, which is applied to mechanical equipment, engine components, variable displacement engines, etc., and can solve problems such as failure to become a power machine and low energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

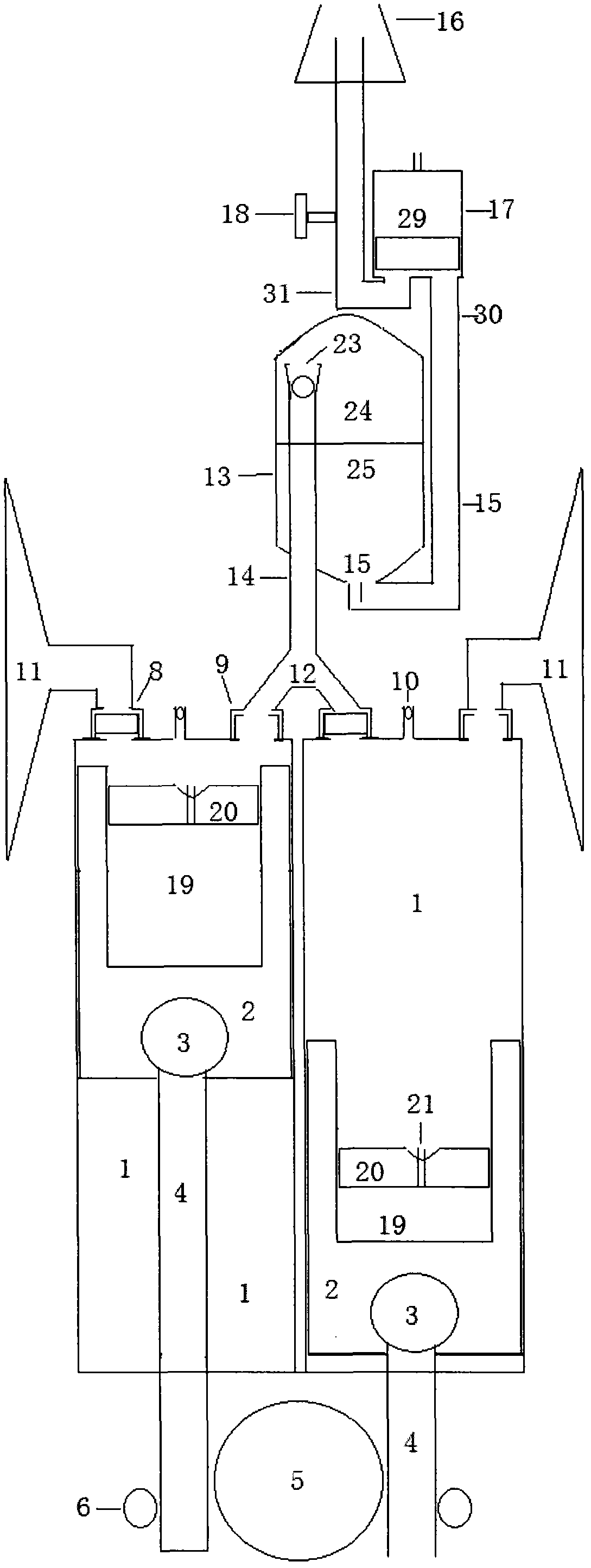

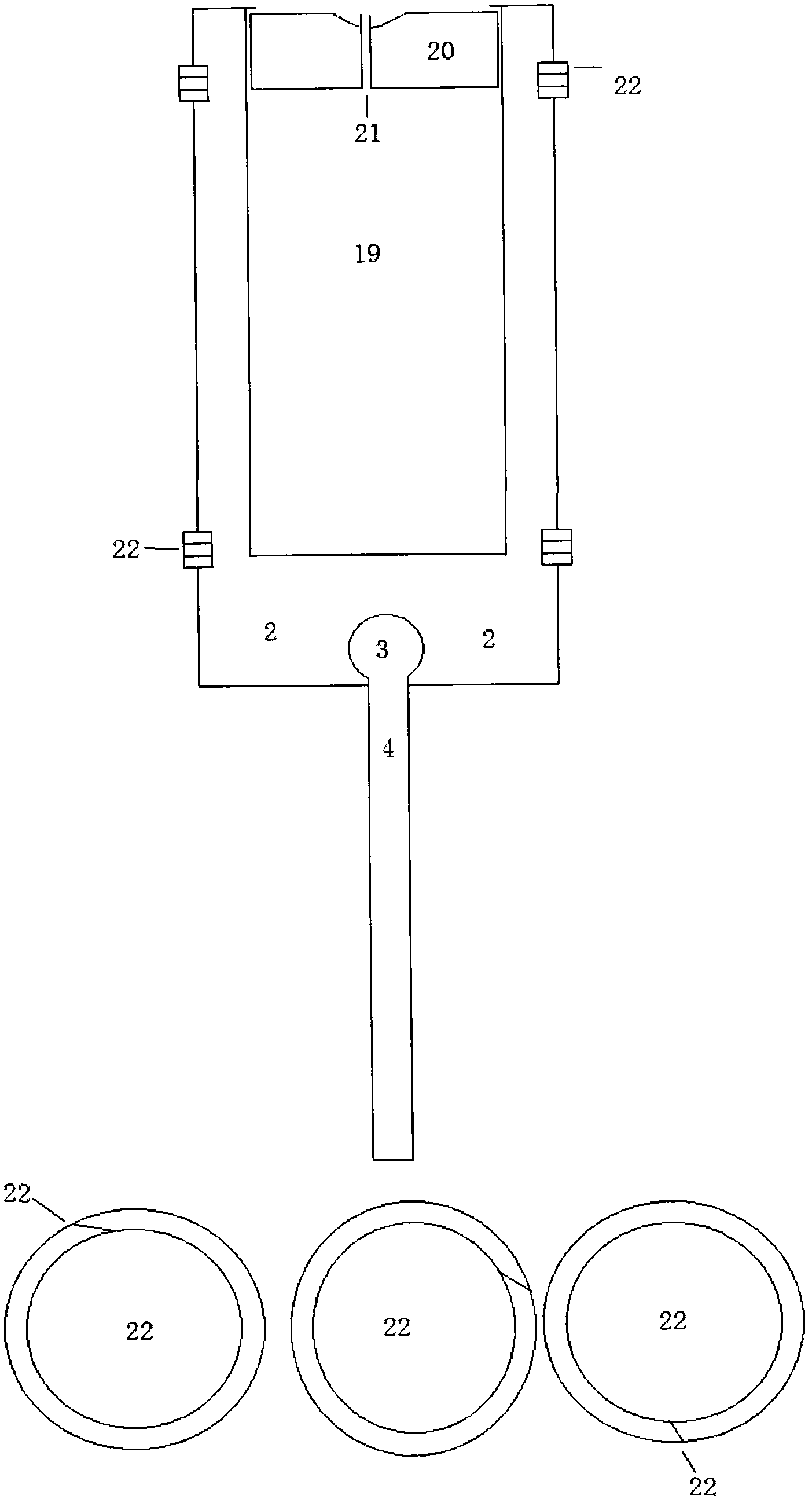

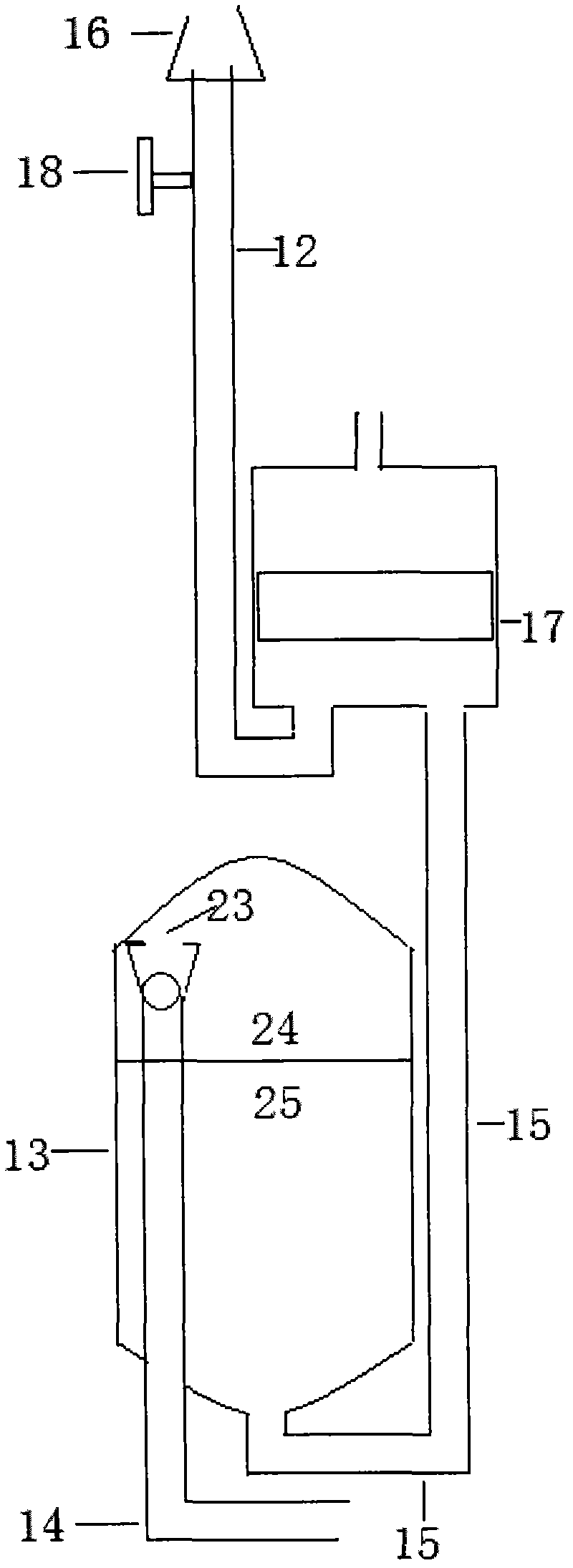

[0024] 1. The fluid energy turbine can work independently by using the atmospheric pressure difference: the fluid energy turbine is placed on the ground or fixed at the bottom of a skyscraper. The exhaust pipe of the fluid energy turbine is not additionally used to communicate with the water pressure pressure converter or the one-way ball valve made of a very light ball at the inlet of the water pressure pressure converter without additional use. The higher the power, the greater the power. The outer outlet of the end of the exhaust pipe is additionally equipped with a single Venturi tube cyclone decompression cover that produces the effect of ejection increase. Use a special tool to preset air or other negative pressure gas with high compression ratio, difficult to dissolve, heat generation, moisture-free inert gas (such as nitrogen) to the compressed gas energy storage chamber through the inlet valve. According to the height of the fluid energy turbine exhaust pipe and other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com