Method for improving carbon sequestration capacity of soil in newly-reclaimed cultivated land area

A soil and new reclamation technology, applied in the field of improving the soil carbon sequestration capacity in newly cultivated and cultivated areas, can solve the problems of quality decline, less consideration of the effect of carbon sequestration and stable yield, and low soil fertility, so as to improve the carbon sequestration capacity and facilitate the Promote, improve the effect of process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

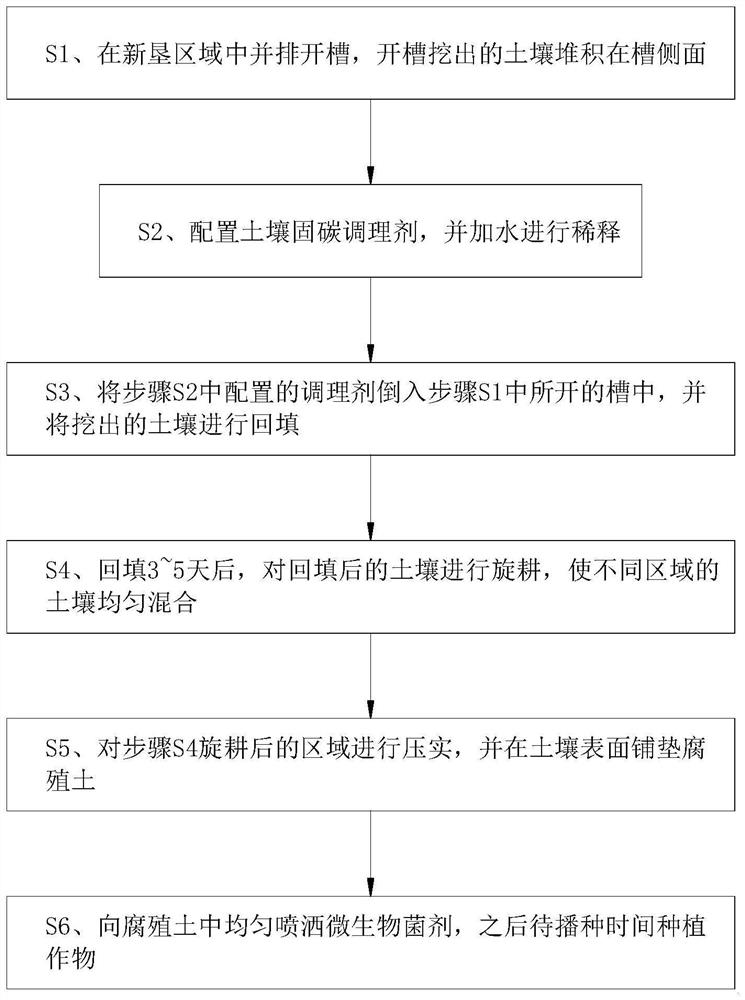

[0025] A method for improving soil carbon sequestration capacity in newly reclaimed cultivated areas, comprising the steps of:

[0026] S1. Drill grooves side by side in the new reclamation area. The depth of the grooves opened is 8cm, the width is 40cm, the distance between adjacent grooves is 25cm, and the excavated soil is piled up on the sides of the grooves;

[0027] S2. According to the components by weight, the components by mass are: 50 parts of crop straw, 20 parts of mineral powder, 10 parts of plant ash, and 10 parts of farmyard manure. The ratio of carbon conditioning agent to water is 1:60 parts;

[0028] S3. Pour the conditioning agent configured in step S2 into the groove opened in step S1, so that the liquid level is below the bottom of the groove by 3 cm, and backfill the excavated soil;

[0029] S4. After backfilling for 3 to 5 days, perform rotary tillage on the backfilled soil, the depth of which is 15cm, and perform three times of rotary tillage on the so...

Embodiment 2

[0033] A method for improving soil carbon sequestration capacity in newly reclaimed cultivated areas, comprising the steps of:

[0034] S1. Drill grooves side by side in the new reclamation area. The depth of the grooves opened is 12cm, the width is 50cm, the distance between adjacent grooves is 35cm, and the excavated soil is piled up on the sides of the grooves;

[0035] S2. According to the components by weight, the components by mass are: 70 parts of crop straw, 30 parts of mineral powder, 20 parts of plant ash, and 20 parts of farmyard manure. The ratio of carbon conditioning agent to water is 1:80 parts;

[0036] S3. Pour the conditioning agent configured in step S2 into the groove opened in step S1, so that the liquid level is below 5 cm from the bottom of the groove, and backfill the excavated soil;

[0037] S4. After backfilling for 3 to 5 days, perform rotary tillage on the backfilled soil, the depth of which is 20cm, and perform four times of rotary tillage on the ...

Embodiment 3

[0041] A method for improving soil carbon sequestration capacity in newly reclaimed cultivated areas, comprising the steps of:

[0042] S1. Drill grooves side by side in the new reclamation area. The depth of the grooves opened is 10cm, the width is 45cm, the distance between adjacent grooves is 30cm, and the excavated soil is piled up on the sides of the grooves;

[0043] S2, according to the components by weight, the components by mass are: 60 parts of crop straw, 25 parts of mineral powder, 15 parts of plant ash, and 15 parts of farmyard manure. The ratio of carbon conditioning agent to water is 1:70 parts;

[0044] S3. Pour the conditioning agent configured in step S2 into the groove opened in step S1, so that the liquid level is below 4 cm from the bottom of the groove, and backfill the excavated soil;

[0045] S4. After backfilling for 3 to 5 days, perform rotary tillage on the backfilled soil. The depth of rotary tillage is 18cm. The soil in the same area is subjected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com