Method for preparing carbon sequestration filler by using waste concrete

A technology of waste concrete and concrete aggregate, which is applied in the field of concrete, can solve the problems of low carbon dioxide absorption rate and short carbonization time, and achieve good carbonization effect and good carbon sequestration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further explained below in conjunction with specific embodiments.

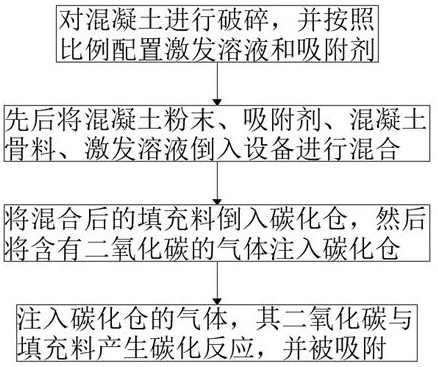

[0021] refer to figure 1 , embodiment one

[0022] In this example, a method for preparing carbon-fixing fillers using waste concrete is proposed, including the following steps:

[0023] Step 1: Preparation of raw materials: First, crush and grind the waste concrete in blocks to obtain concrete aggregate and concrete powder respectively. The ratio is controlled at 1:1, the concrete aggregate is fine aggregate, the diameter is less than 4.75mm, the specific surface area of the concrete powder is ≥600㎡ / kg, the excitation solution and adsorbent are configured, and the weight ratio of waste concrete, excitation solution and adsorbent It is: 10:10:3, the excitation solution is composed of sodium carbonate, potassium carbonate and water, the weight ratio of sodium carbonate, potassium carbonate and water is: 2:1:100, the adsorbent is composed of zeolite imidazolate framework ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com