Magnet pyrolysis reactor

A technology of pyrolysis reactor and magnet, which is applied in the direction of electric heating coke oven, heating of coke oven, special form of dry distillation, etc. It can solve the problems of operational and economic impossibility, inefficiency, unreliability, etc., and achieve the effect of carbon sequestration Good, high efficiency, effect of reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

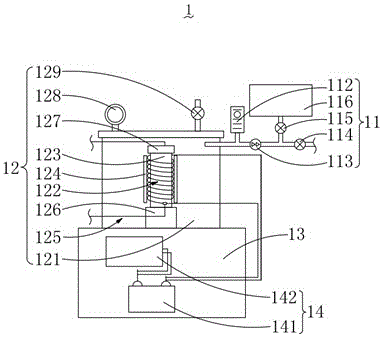

[0021] see figure 1 , is a schematic structural view of the magnet pyrolysis reactor provided by the present invention.

[0022] The magnet pyrolysis reactor 1 includes a vacuum system 11 , a pyrolysis chamber 12 , a storage chamber 13 and a power supply 14 .

[0023] The pyrolysis chamber 12 includes a cavity 121 , a coil 122 , a heat pipe 123 , a soft magnet 124 , a cooling pipe 125 , a solid-liquid outlet 126 , a filter 127 , a vacuum gauge 128 and a pressure regulating valve 129 .

[0024] The heat pipe 123 is disposed in the cavity 121 , the solid-liquid outlet 126 is disposed at the bottom of the heat pipe 123 , and the filter 127 is disposed at the top of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com