Recovery system and method for nitrous oxide in nitrogen trifluoride gas

A technology of nitrous oxide and nitrogen trifluoride, which is applied in the fields of nitrous oxide, chemical instruments and methods, nitrogen oxides/oxyacids, etc., and can solve problems such as environmental pollution and waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

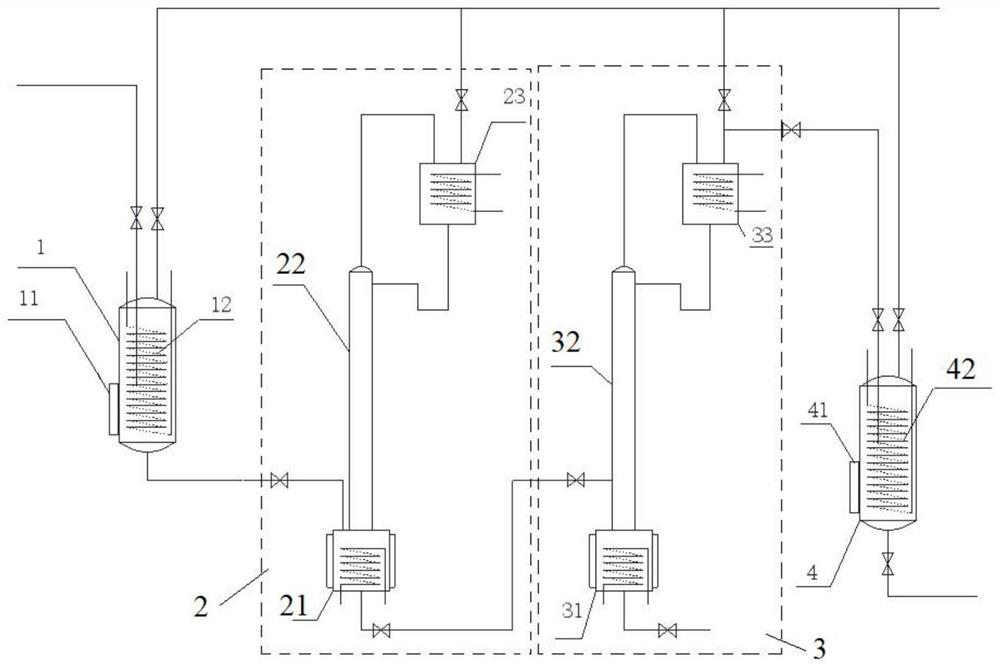

[0065] use figure 1 The recovery system shown is for the recovery of nitrous oxide in nitrogen trifluoride:

[0066] In the nitrogen trifluoride rectification process, nitrous oxide is continuously enriched in the nitrogen trifluoride rectification and weight removal tower, and when the volume fraction of nitrous oxide in the tower liquid reaches 60-80%, it is intermittently transferred to the crude product container 1 collection. Utilize the first condenser 12 in the crude product container 1, control the temperature of low-temperature liquefaction at -110°C, and control the pressure at 0.1 to 0.3 MPa for receiving; . At this temperature and pressure, nitrous oxide exists as a solid and nitrogen trifluoride exists as a gas. When the pressure reaches or approaches 0.3 MPa, open the discharge valve at the top of the crude product container 1 to release the pressure to 0.1 MPa to the nitrogen trifluoride crude product gas holder. When the receiving volume of the crude produc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap