Construction method for drilling and pile forming of hydraulic down-the-hole hammer

A construction method and technology of down-the-hole hammer, which are applied to drilling equipment and methods, sheet pile walls, drilling equipment, etc., can solve problems such as not being able to play their advantages well, save time for repeated dismantling and layout, and ensure construction. Efficiency, the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

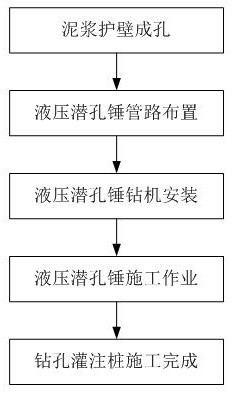

[0026] Such as figure 1 As shown, a construction method of hydraulic DTH hammer drilling into piles is based on the mud wall drilling rig, hydraulic DTH hammer and its supporting pipeline system and slurry circulation system. The following steps are used to efficiently carry out deep drilling operations and form a drill Construction method of cast-in-place pile:

[0027] Step 1: Make holes in the mud retaining wall;

[0028] Use rotary excavation or reverse circulation or positive circulation mud retaining technology to drill holes into strongly weathered rock formations or moderately weathered rock formations, and the mud retaining wall drilling equipment will be displaced;

[0029] Step 2: Hydraulic DTH hammer pipeline layout;

[0030] The hydraulic down-the-hole hammer drilling rig is in place, and the slurry return pipeline, mud pool, hydraulic down-the-hole hammer drilling rig, slurry discharge pipeline, and slag remover are arranged in sequence, and the slag remover is...

Embodiment 2

[0041] In the working condition, the upper 20m soil layer is a clay layer or a sand layer, and the following 20m is a strong weathered rock layer, and the design pile length is 25m. Adopt the technical scheme introduced by the present invention to carry out the following construction:

[0042] Such as figure 1 As shown, based on the mud protection drilling rig, hydraulic down-the-hole hammer and its supporting pipeline system and slurry circulation system, the construction method of forming bored piles is as follows:

[0043] Step 1: Make holes in the mud retaining wall;

[0044] The rotary drilling process is used to drill into the strong weathered rock formation at a distance of 20m, and the rotary drilling rig is displaced;

[0045] Step 2: Hydraulic DTH hammer pipeline layout;

[0046] The hydraulic down-the-hole hammer drilling rig is in place, and the slurry return pipeline, mud pool, hydraulic down-the-hole hammer drilling rig, slurry discharge pipeline, and slag remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com