Dynamic air compensation and heat management system of diesel engine

A thermal management system, diesel engine technology, applied in the direction of charging system, machine/engine, fuel air intake, etc., can solve the problems of reducing the conversion efficiency of after-treatment devices, reducing engine efficiency, increasing air intake resistance, etc., to achieve improvement Low-speed response performance, improved exhaust emissions, and increased exhaust temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

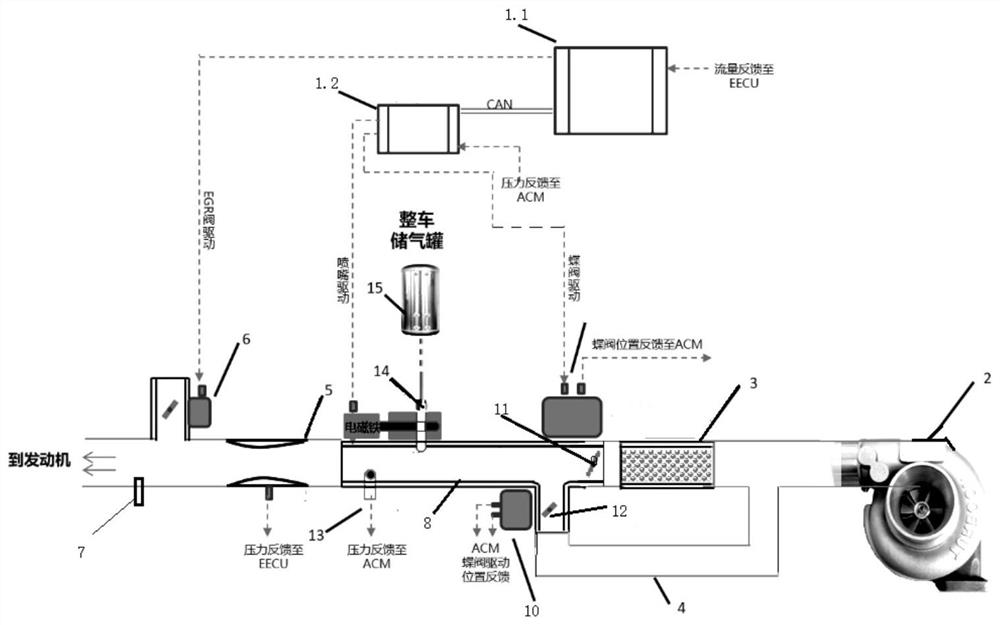

[0029] Such as figure 1 As shown, the present invention provides a dynamic air compensation and thermal management system for a diesel engine, including a supercharger 2 and an engine, wherein the air outlet of the supercharger 2 communicates with the intake port of the engine through a pipeline. The pipeline between the supercharger 2 and the engine intake pipe is a pipeline with a three-way function. When the engine is working, the turbocharging device is used to increase the engine output torque without increasing the engine displacement; the intake air intercooling device is used to cool the high-temperature air after turbocharging to increase the intake charge.

[0030] The pipeline between the air outlet of the supercharger...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap