Fatigue crack propagation fracture toughness testing machine

A technology of fatigue crack propagation and fracture toughness, applied in the field of testing machines, can solve the problems of long time for cleaning debris and low cleaning efficiency, and achieve the effect of reducing manual operation and improving cleaning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following is attached Figure 1-4 The application is described in further detail.

[0032] The embodiment of the present application discloses a fatigue crack growth fracture toughness testing machine.

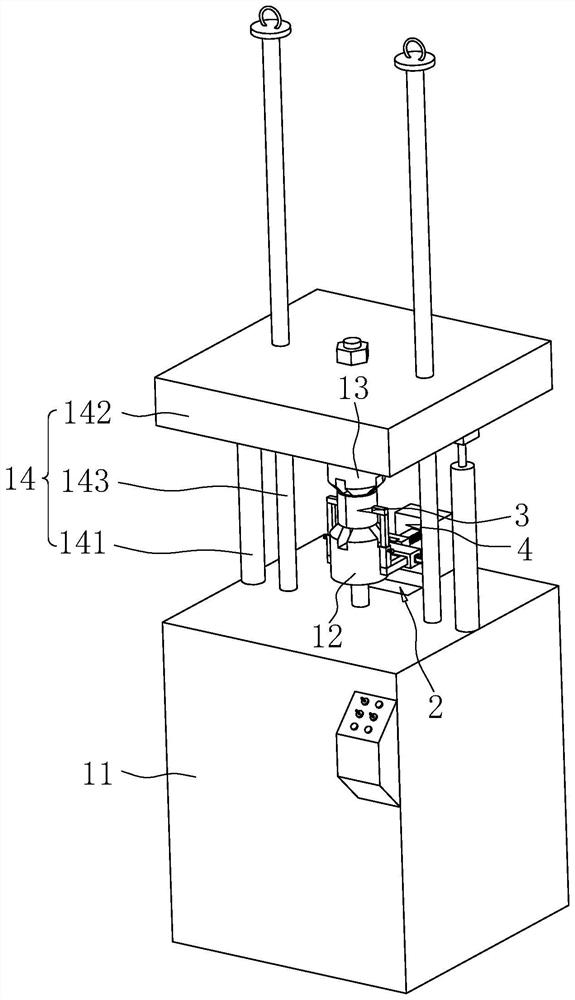

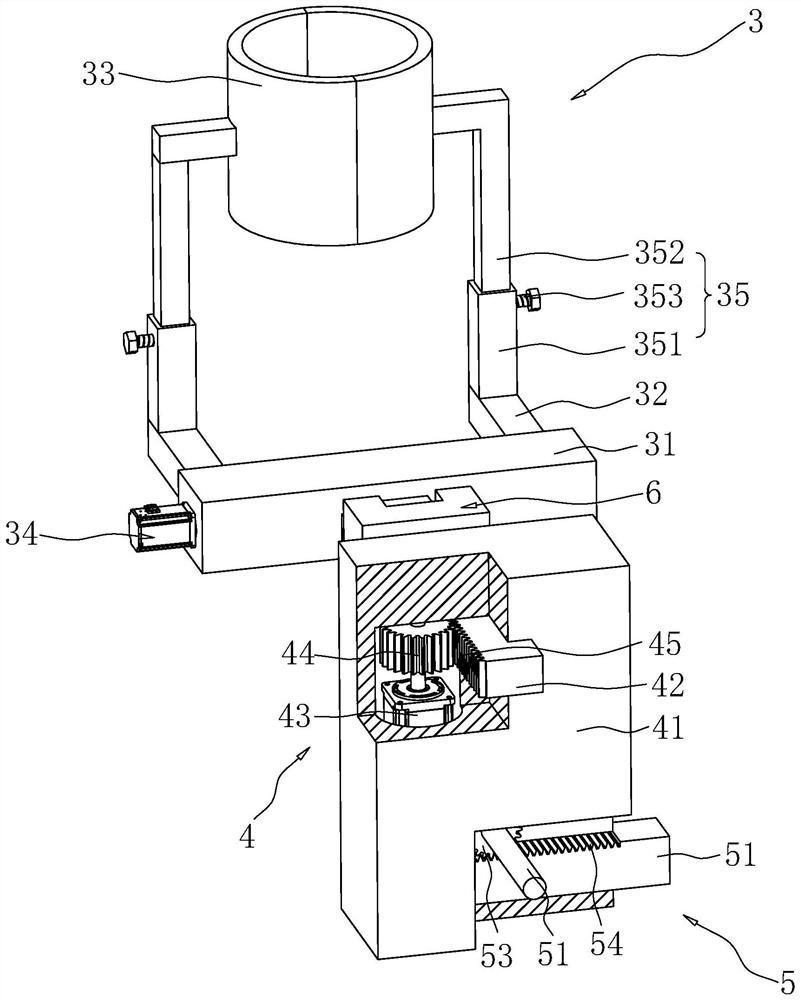

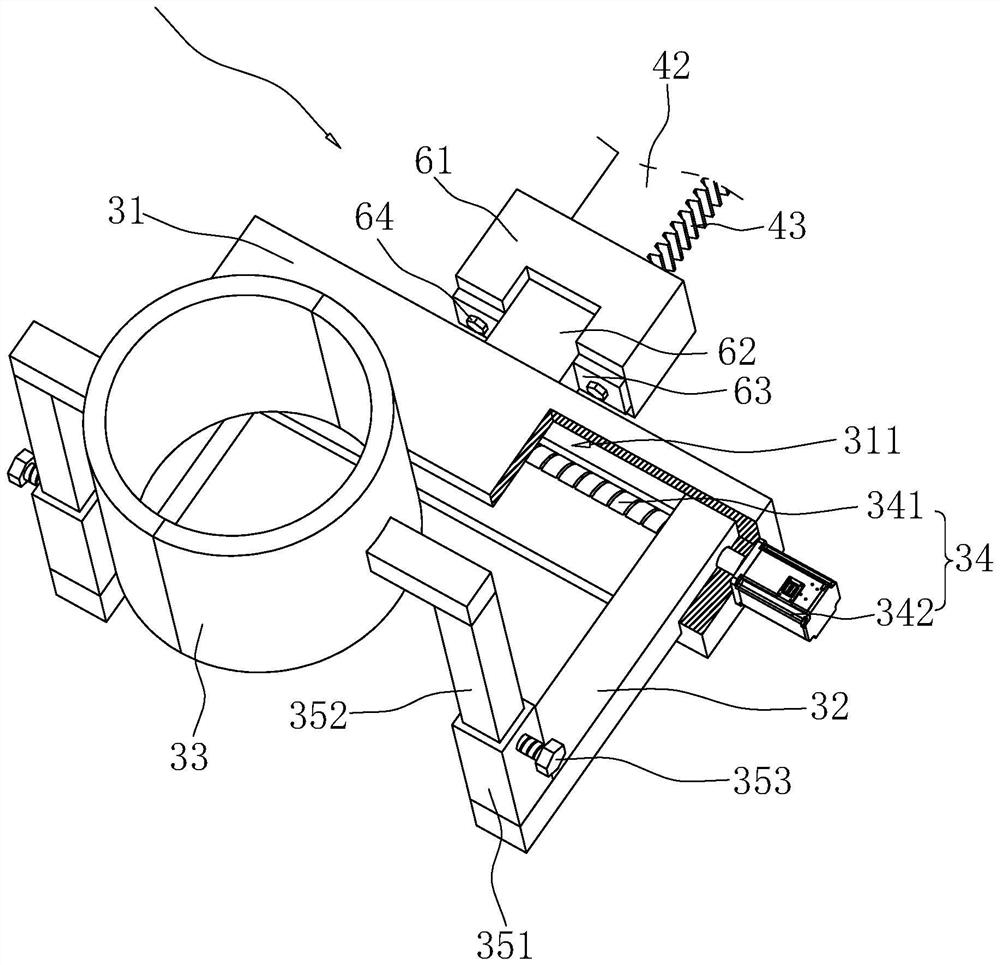

[0033] refer to figure 1 , the fatigue crack growth fracture toughness testing machine includes a main body 11, the lower end of the main body 11 is fixedly connected with a first clamp 12; the main body 11 is provided with a moving assembly 14, and the mobile assembly 14 is provided with a second clamp 13; the main body 11 is provided with a cleaning mechanism 2; The main body 11 is provided with a protective device 3 .

[0034] One end of the workpiece with fatigue cracks is clamped by the first clamp 12 and the other end is clamped by the second clamp 13, and then the protective device 3 protects the workpiece; the moving assembly 14 is started, and the moving assembly 14 drives the second clamp 13 toward away from The directional movement of the first fixture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com