Battery module welding process

A welding process and battery module technology, applied in battery pack components, secondary batteries, circuits, etc., can solve problems such as affecting the yield of battery modules, no pre-fixing of tabs, and high welding defect rate, and improve the The effect of production efficiency and welding production quality, reducing product scrap, and reducing welding defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

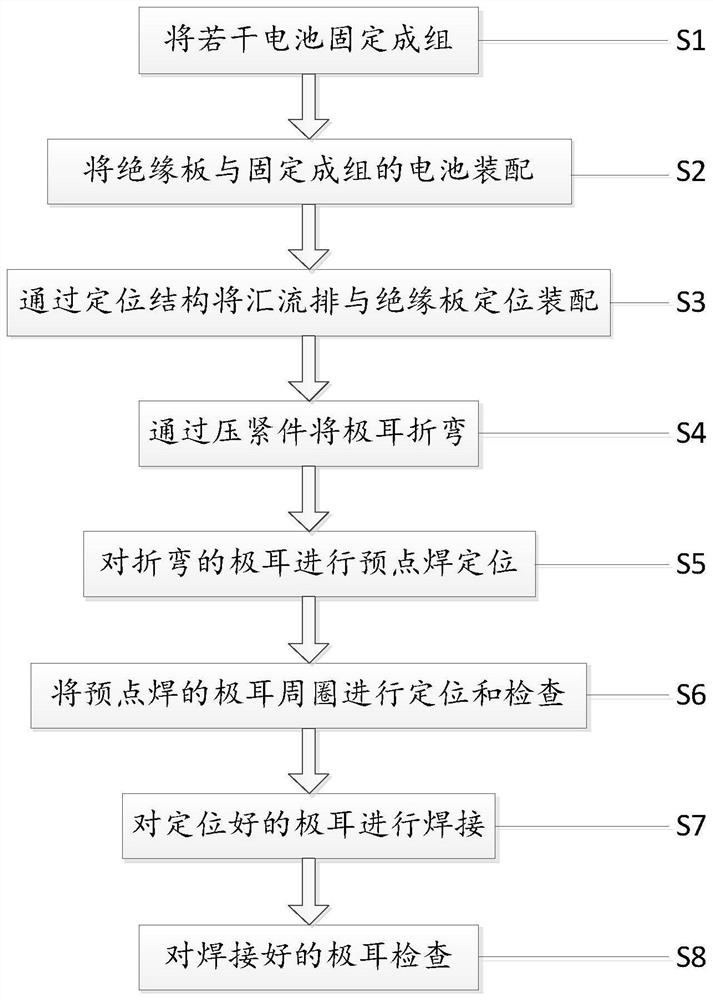

[0022] Such as figure 1 As shown, a battery module welding process specifically includes the following steps:

[0023] S1: Fix some batteries into groups;

[0024] S2: Assembling the insulating plate with the batteries fixed into groups;

[0025] S3: Position and assemble the busbar and the insulating plate through the positioning structure, and control the distance between the busbars;

[0026] S4: Bending the tab through the pressing piece;

[0027] S5: performing pre-spot welding positioning on the bent tab;

[0028] S6: Positioning and checking the pre-spot-welded lug circumference;

[0029] S7: welding the positioned tabs;

[0030] S8: Check the welded lugs.

[0031] Before several batteries are fixed into a group, it is necessary to check the tab surface of the battery. If there is no damage on the tab surface, it can be fixed into a group. If there is any damage, just replace the intact battery.

[0032] Specifically, in the above-mentioned S1, spacers are provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com