Deep-fertilization secondary-pressing full-width uniform sowing machine and sowing method

A technology of deep fertilization and suppressor, which is applied in the field of deep fertilization, secondary suppression, full-width even seeding machine and sowing field, which can solve the problem that the promotion of seed growth does not have a very good effect, achieve the effect of moisture conservation, good effect, and reduce water loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

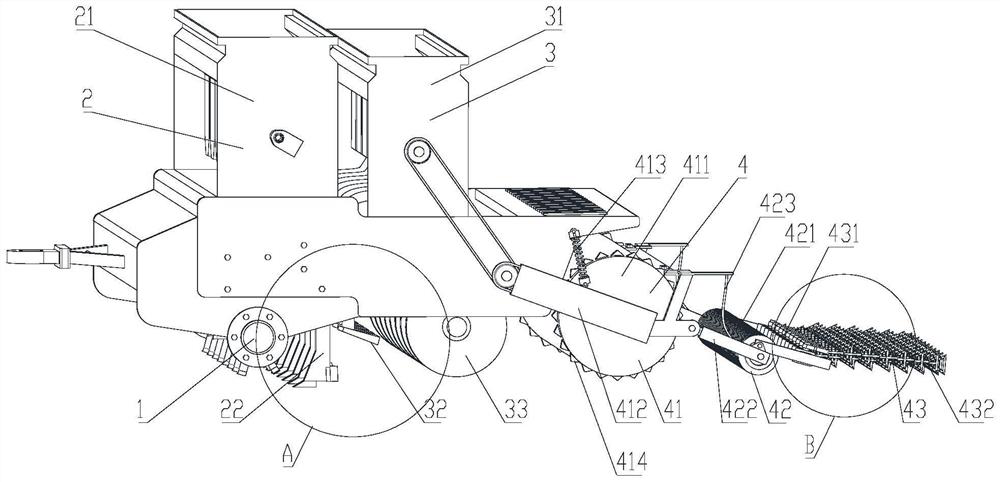

[0060] see Figure 1 to Figure 4 , the present invention provides a deep fertilization secondary suppression full-width leveling machine, comprising a rotary tiller 1, a fertilization unit 2, a seeding unit 3 and a soil covering unit 4 arranged in sequence;

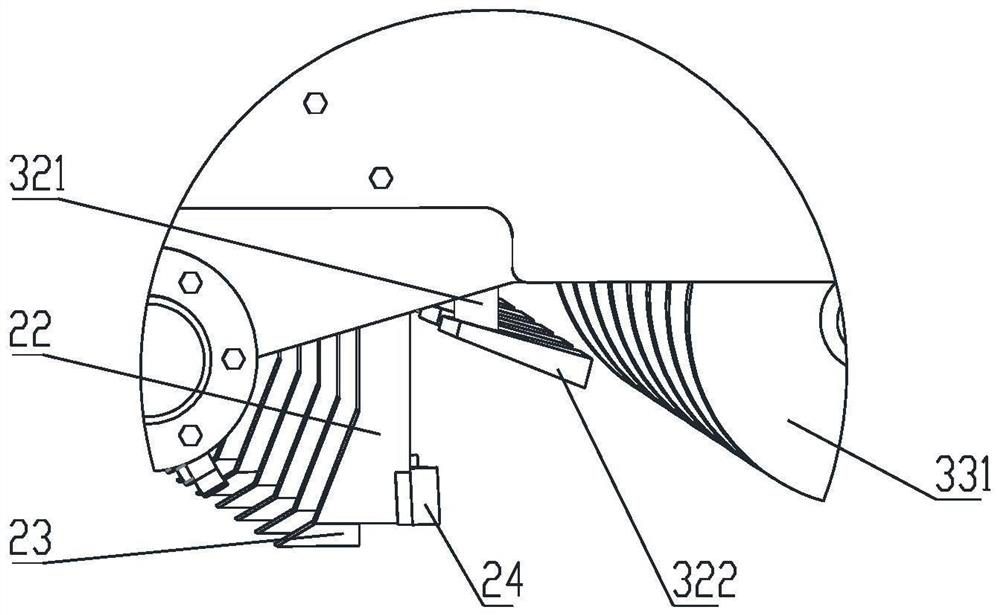

[0061] The fertilization unit 2 comprises a fertilizer box 21 positioned at the top, and a feeding assembly is arranged in the fertilizer box 21, and the fertilizer box 21 is connected with some fertilization pipes 22 by the feeding assembly, and the fertilization pipe 22 is arranged on the lower side of the fertilizer box 21, and the inside of the fertilization pipe 22 is hollow. The fertilization pipe communicates with the inside of the fertilizer box 21 through the feeding assembly, and the lower end of the fertilization pipe 22 is provided with a fertilizer outlet; the side of the fertilization pipe 22 facing the rotary blade 1 is fixedly provided with a bump 23;

[0062] The sowing unit 3 includes a seed box 31 posit...

Embodiment 2

[0081] see figure 2 , On the basis of Embodiment 1, the bump 23 is a right-angled trapezoidal block, and the end of the bump 23 facing the rotary blade 1 is a tip. The bump 23 of this shape has better stability and is more helpful for ditching.

[0082] The main suppressor 41 is suspended on the rear portion of the seeder housing by the main hanger 412, and the auxiliary suppressor 42 is connected with the main hanger 412 by the auxiliary hanger 422;

[0083] One end of the main hanger 412 is rotatably connected to the seeder housing, the other end is rotatably connected to the auxiliary hanger 422, and the middle part of the main hanger 412 is rotatably connected to the roller 411;

[0084] An adjustment rod 413 is also arranged between the main hanger 412 and the seeder housing, and the two ends of the adjustment rod 413 are rotatably connected with the seeder housing and the main hanger 412 respectively.

[0085] The adjusting rod 413 is a screw spring combination, inclu...

Embodiment 3

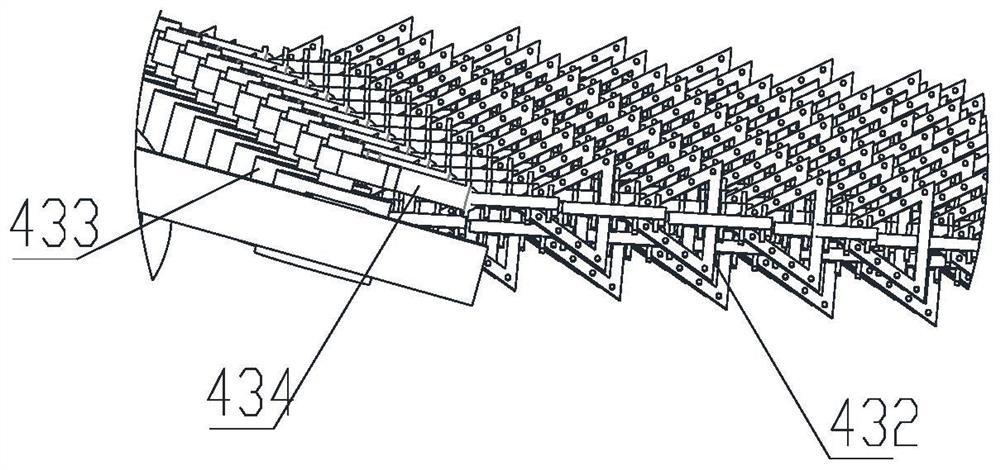

[0089] On the basis of the above-mentioned embodiment, the auxiliary suppressor 42 includes a suppressing roller 421, and the suppressing roller 421 is composed of a number of diamond-shaped rubber wheels and disc arrays, the diamond-shaped rubber wheels and the discs are coaxial, and the diamond-shaped rubber wheels and the discs are coaxial Alternate settings.

[0090] The disk is a metal disk.

[0091] An upper pole is fixedly arranged on the upper side of the main hanger 412 , and the auxiliary hanger 422 is connected with the upper pole of the main hanger 412 by a hanging chain 423 . It is different from the form in which the main hanger 412 adjusts the height of the roller 411 through the adjusting rod 413 . The pressing roller 421 and the auxiliary hanger 422 hang down only by their own weight, because the dead weight of the pressing roller 421 is much lower than that of the roller 411, so there is no need to set the adjustment assembly. After being lifted, the hangin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com