Water-based paint stirring, monitoring and feeding device

A technology of feeding device and water-based paint, which is applied to mixers with rotary stirring devices, mixer accessories, transportation and packaging, etc., which can solve the problems of unfavorable operating conditions, inability to monitor and control the mixing status of the mixing bin, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

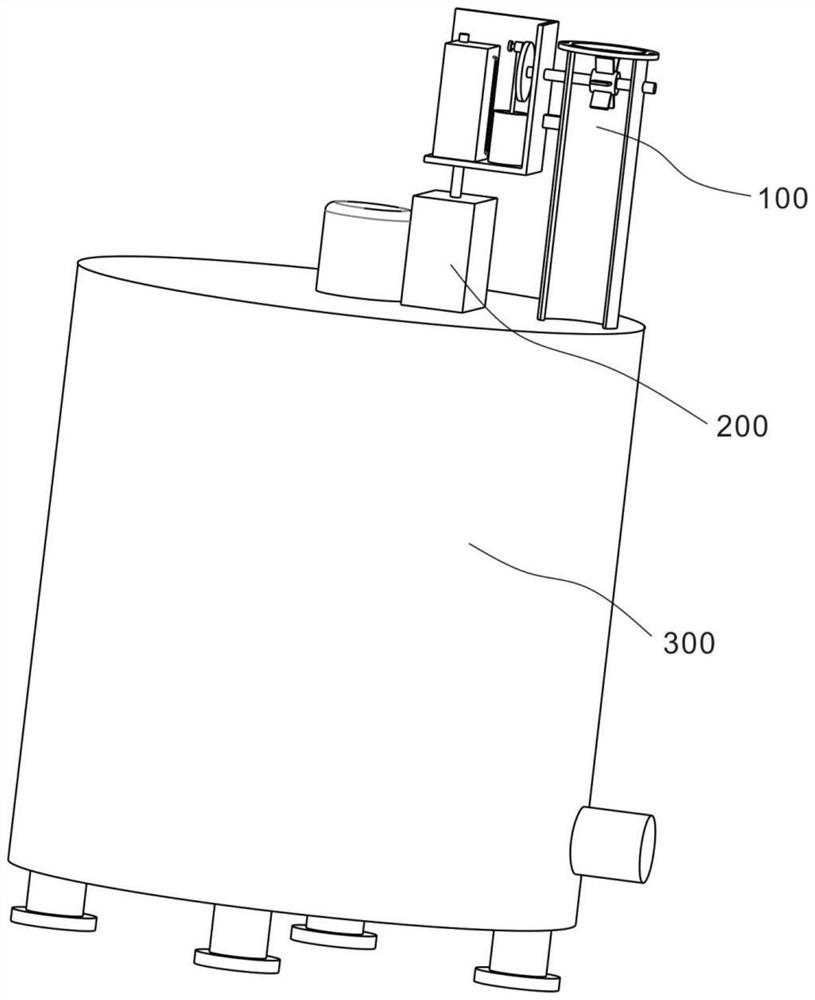

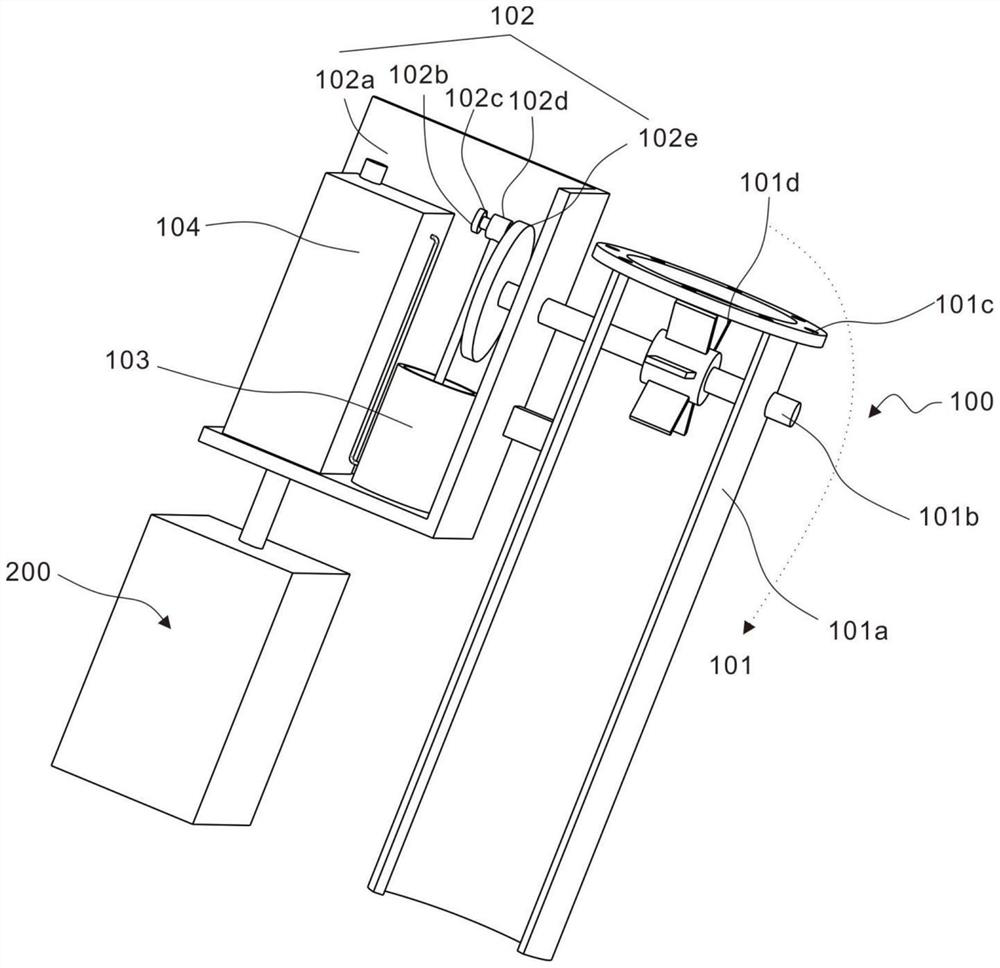

[0029] refer to figure 1 , 2 , is the first embodiment of the present invention, this embodiment provides a water-based paint stirring monitoring feeding device, including a power output module 100, the power output module 100 includes a feed assembly 101, a reciprocating assembly 102, a pressurization assembly 103 and the hydraulic assembly 104, the feed assembly 101 is movably connected with the reciprocating assembly 102, the reciprocating assembly 102 is movably connected with the pressurization assembly 103, the pressurization assembly 103 is movably connected with the hydraulic assembly 104, and both the pressurization assembly 103 and the hydraulic assembly 104 are set within the reciprocating assembly 102;

[0030] During the feeding process of the equipment, the gravitational potential energy of the material falling is converted into mechanical energy by the paddle wheel 101d in the feeding assembly 101, which drives the installation rod 101b to rotate, and transmits...

Embodiment 2

[0034] refer to Figure 2-6 , is the second embodiment of the present invention, which is based on the previous embodiment.

[0035] The feed assembly 101 includes a feed pipe 101a, a mounting rod 101b and a paddle wheel 101d, both sides of the mounting rod 101b run through the feed pipe 101a, the paddle wheel 101d is arranged in the feed pipe 101a, and the paddle wheel 101d is arranged on the mounting rod On the surface of 101b, during the equipment feeding process, the gravitational potential energy of the falling material drives the paddle wheel 101d to rotate, and the rotation of the paddle wheel 101d drives the installation rod 101b to rotate, and the power is transmitted to the reciprocating component 102 through the rotation of the installation rod 101b ;

[0036]The reciprocating motion assembly 102 includes a mounting shell 102a, a protective piece 102b, a movable rod 102c, a movable sleeve 102d and a wheel disc 102e, one end of the wheel disc 102e is fixedly connect...

Embodiment 3

[0042] refer to Figure 2-6 , is the third embodiment of the present invention, which is based on the above two embodiments.

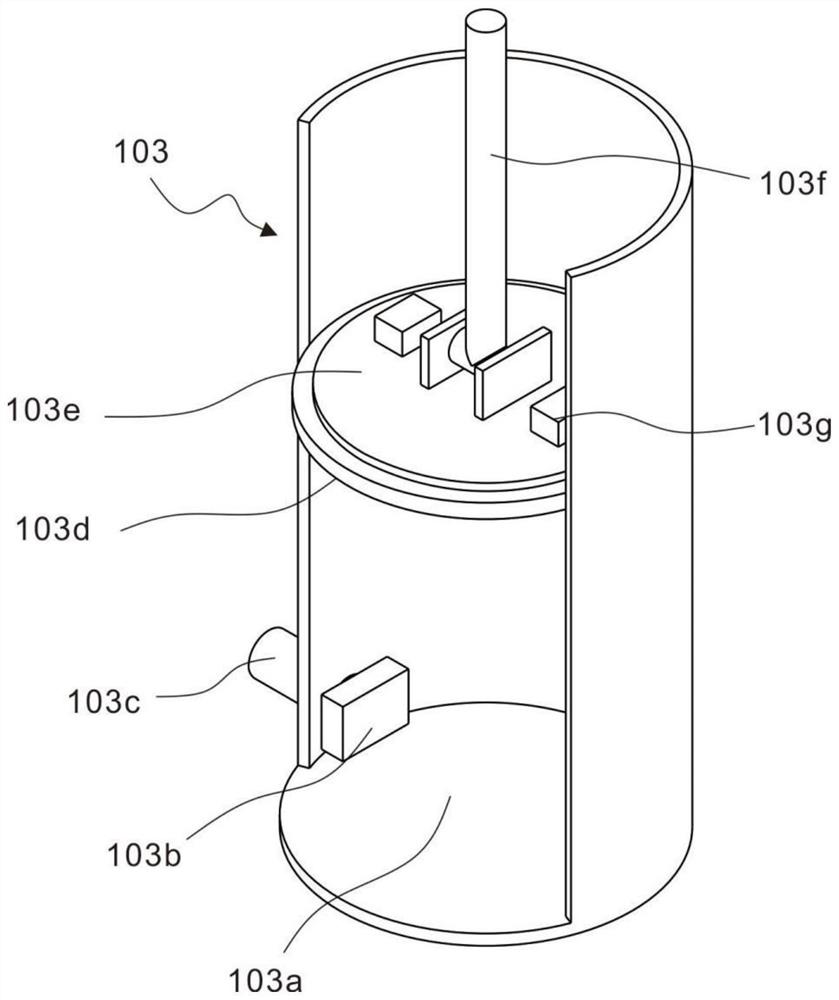

[0043] The booster assembly 103 also includes a first one-way valve 103b, a piston ring 103d and a second one-way valve 103g, the first one-way valve 103b is arranged on the end surface of the air outlet conduit 103c, and the piston ring 103d is arranged on the outer surface of the piston 103e , the second one-way valve 103g is arranged on the surface of the piston 103e, through the use of the piston ring 103d, the effect of the piston 103e on air compression during the moving process can be better, so that the air intake efficiency in the hydraulic assembly 104 is higher, through The use of the first one-way valve 103b and the second one-way valve 103g can make the equipment more efficient during the air compression process. When the piston 103e moves from top to bottom in the compression chamber 103a, the second one-way valve 103g is closed, The fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com