Deep stirring injection remediation method based on in-situ oxidation remediation of soil

A technology for deep stirring and soil remediation, applied in the restoration of polluted soil, etc., can solve the problems of unsatisfactory application effect, slow penetration of chemical reagents, insufficient contact, etc., to achieve sufficient contact, reasonable method design, and construction consumption. short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

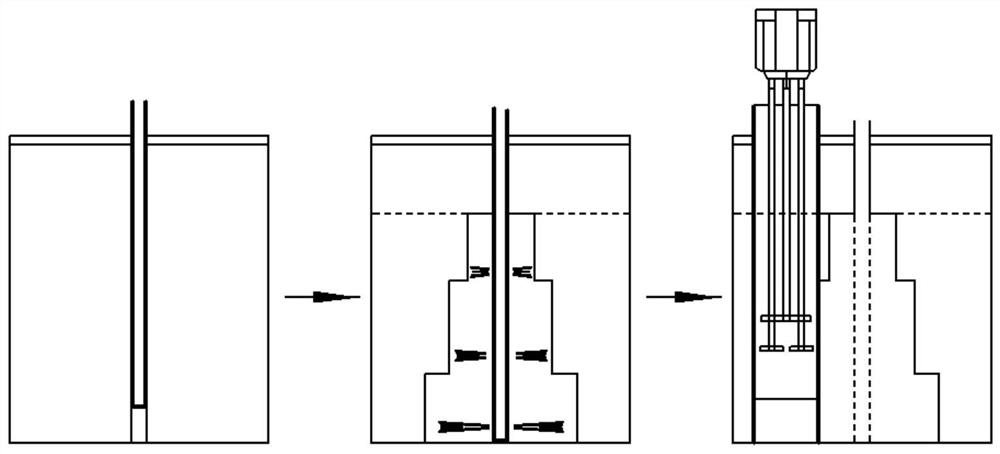

[0049] Embodiment 1: A deep stirring injection repair method based on in-situ oxidation repair soil, specifically including:

[0050] S1: Preliminary soil preparation

[0051] S1-1: On-site deep sampling and analysis

[0052] Set soil sampling holes, take samples and analyze the collected soil samples;

[0053] S1-2: Preparation of oxidizing agents

[0054] According to the results of soil sample analysis, accurately determine the pollution concentration at each depth in different areas, and further adjust the amount of oxidizing agent used for soil restoration;

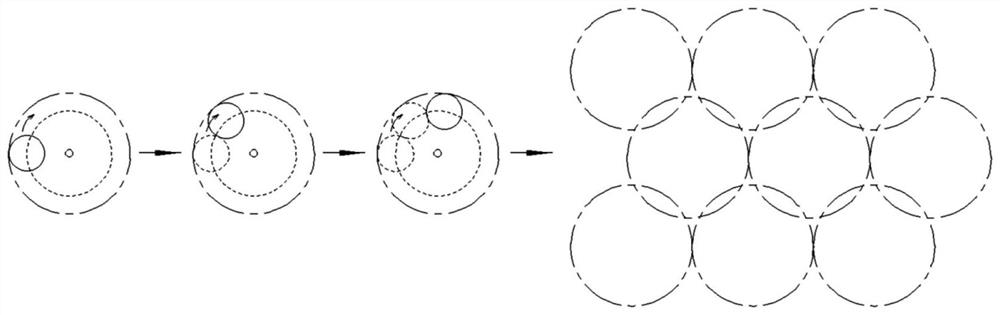

[0055] S1-3: Segmentation of the soil to be remediated

[0056] According to the pollution concentration, a simple segmentation module is set on the area to be repaired to divide the area to be repaired into different area modules according to different pollution degrees; then configure the required oxidizing agents in the corresponding area modules;

[0057] S2: Pre-protection processing

[0058] S2-1: Site Lev...

Embodiment 2

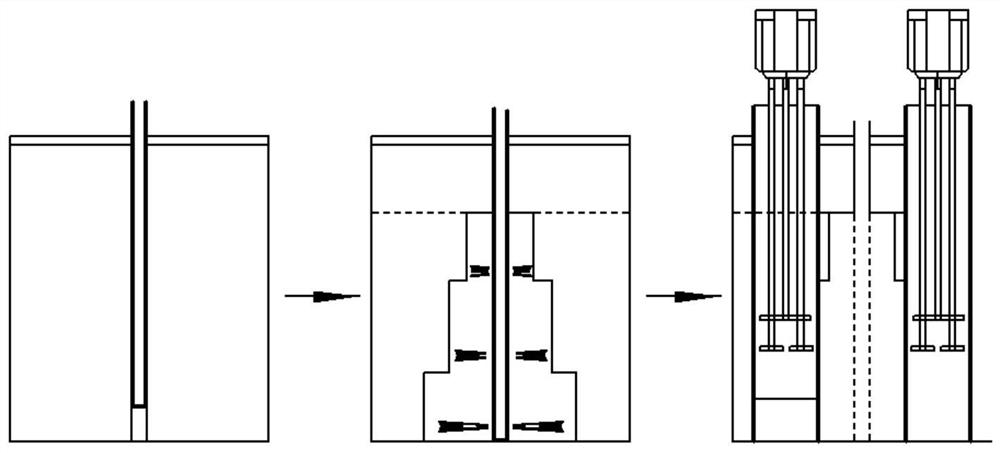

[0077] Embodiment 2: A deep stirring injection repair method based on in-situ oxidation repair soil, specifically including:

[0078] S1: Preliminary soil preparation

[0079] S1-1: On-site deep sampling and analysis

[0080] Set soil sampling holes, take samples and analyze the collected soil samples;

[0081] S1-2: Preparation of oxidizing agents

[0082] According to the results of soil sample analysis, the concentration of pollution at each depth in different regions is accurately determined, and the amount of oxidizing agent used for repairing the soil is further adjusted; the oxidizing agent is specifically a mixture of persulfate and transition metal ions;

[0083] S1-3: Segmentation of the soil to be remediated

[0084] According to the pollution concentration, a simple segmentation module is set on the area to be repaired to divide the area to be repaired into different area modules according to different pollution degrees; then configure the required oxidizing age...

Embodiment 3

[0106] Embodiment 3: The difference from Embodiment 2 is that the oxidizing agent is specifically a mixture of persulfate and strong alkali.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface area | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com