Production process of welded pipe formed by bending and welding after slitting and punching

A technology of welding forming and production technology, which is applied in the production of square pipes and round pipes, can solve the problems of low processing efficiency, easily damaged dies, and easy deformation, and achieve the effect of expanding the range of specifications, expanding production specifications, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

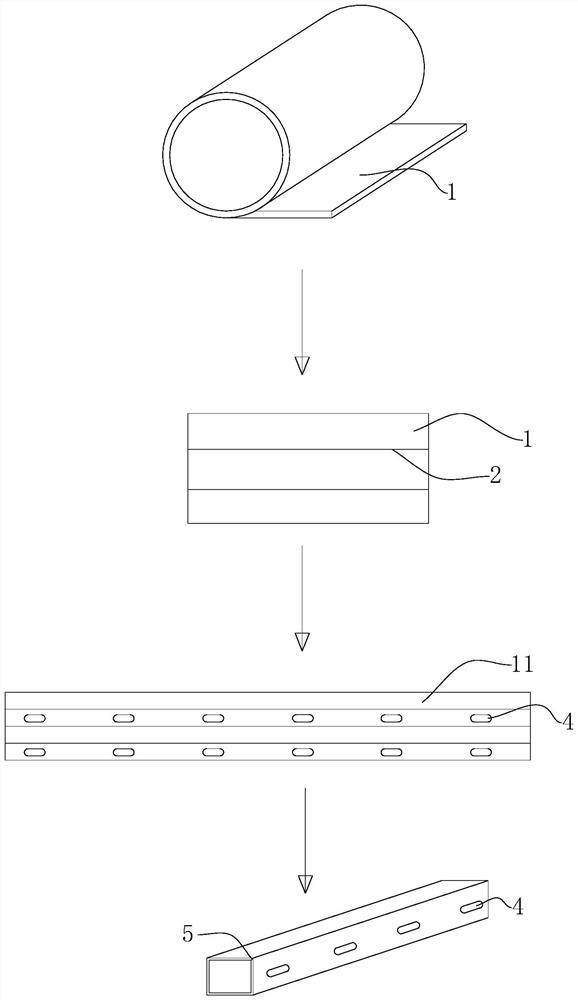

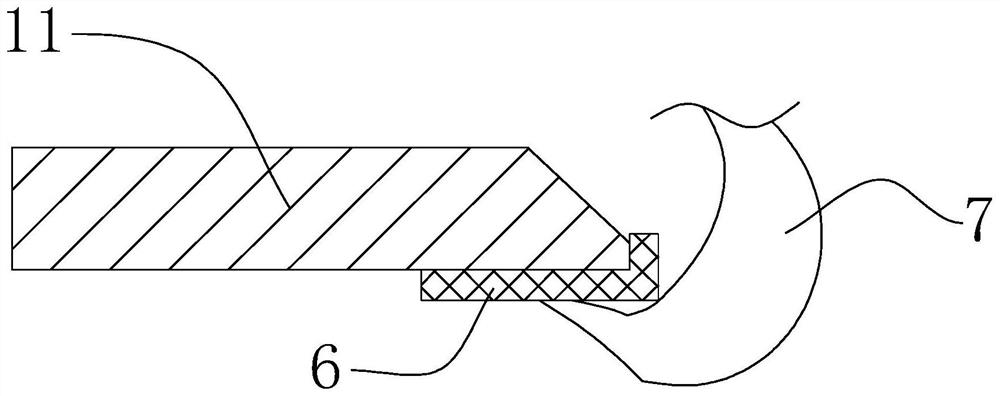

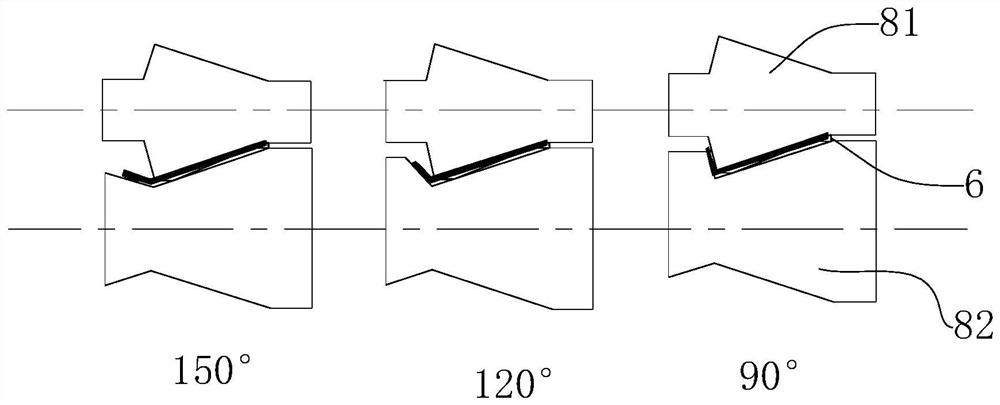

[0031] refer to figure 1 Shown, a kind of welded pipe production process of bending and welding forming after punching in strips is characterized in that it comprises the following steps:

[0032] A. Feeding: The steel belt 1 material in the form of a reel is hoisted and placed on the roller frame. One end of the steel belt 1 is fixed by the tractor, and the tractor moves on the horizontal track to pull the steel belt 1 and sends it into the drum unit;

[0033] B. Position correction: the camber is corrected by the roller unit, and the deviation correction guide wheel mechanism is installed on the roller unit, and the force is adjusted on both sides of the steel belt 1 to keep the steel belt 1 in the center position;

[0034] C. Cutting and slitting: the straight steel strip 1 is cut and slitted by a cutting machine, and the width of the slitting is adjusted by the spacing adjustment mechanism of the cutting machine to form a steel strip 11 whose width meets the set value;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com