Raw material premixing device for 3D printing

A 3D printing and raw material technology, applied in the field of material processing, can solve the problem of uneven mixing of materials and achieve the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

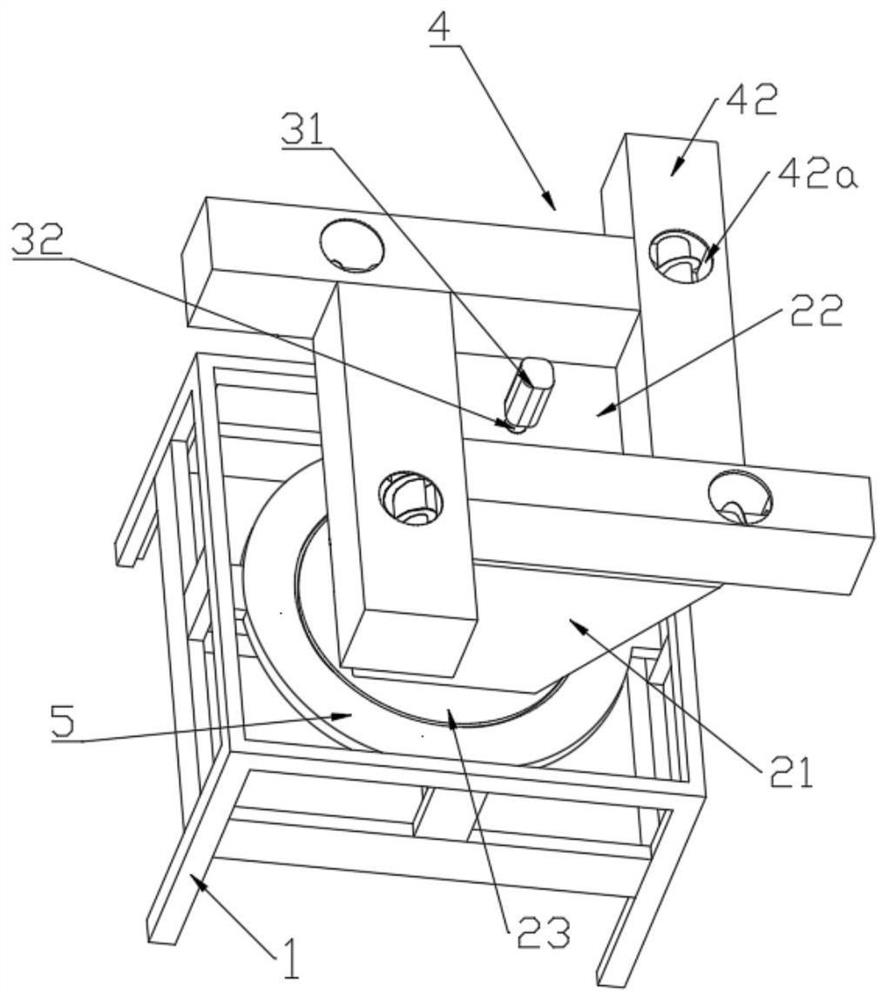

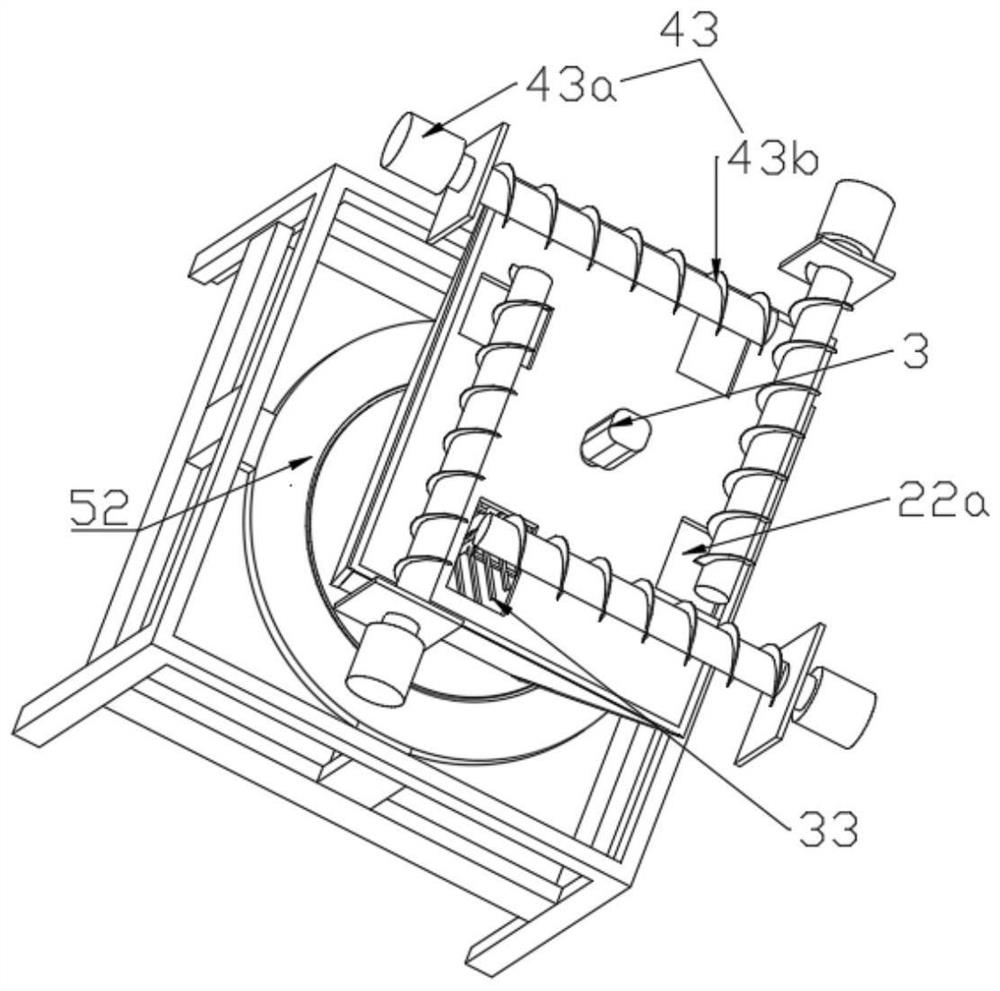

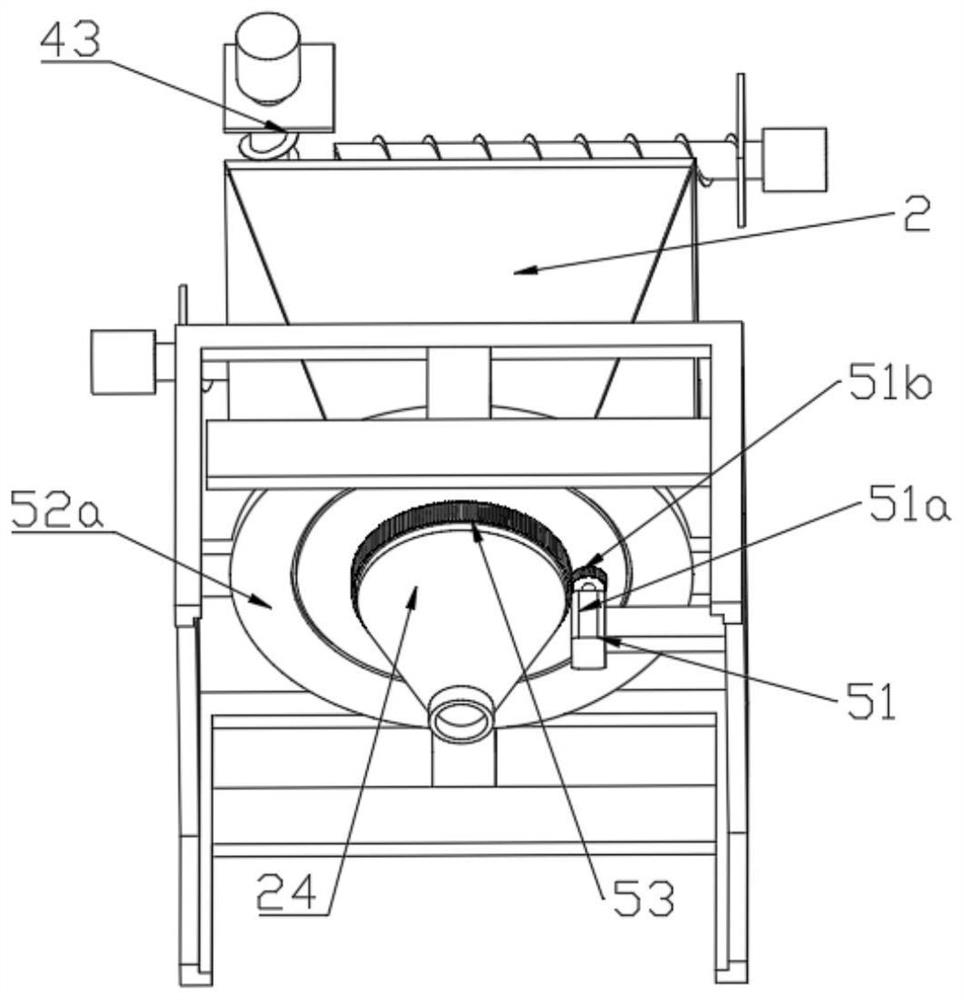

[0030] Such as Figure 1-4 As shown, a raw material premixing device for 3D printing provided by the present invention includes a support frame 1, a stirring bucket 2, a stirring mechanism 3, a raw material preset mechanism 4, a rotating mechanism 5, a pre-stirring structure 6, a mounting frame 7 and an upper Material device 8.

[0031] Among them, such as Figure 1-3 As shown, the mixing bucket adopts the shape of a square bucket cup. The mixing bucket includes a trapezoidal side plate 21 and a square top plate 22. A conical discharge hopper 24 is installed at the lower end of the mixing bucket. The stirring mechanism is installed on the On the stirring bucket, the stirring mechanism includes a stirring motor 31 fixed on the square top plate, a stirring shaft 32 extending into the stirring bucket, and a stirring rod 33 connected to the stirring shaft. The shaft 32 and the stirring rod 33 extend into the conical discharge hopper 24, and a pneumatic butterfly valve is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com