Rapid cooling injection mold and injection molding system thereof

A rapid cooling, injection mold technology, applied in the field of injection molds, can solve the problems of poor cooling efficiency, different cooling capacity, different accumulation of molten plastic, etc., to achieve the effect of improving cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

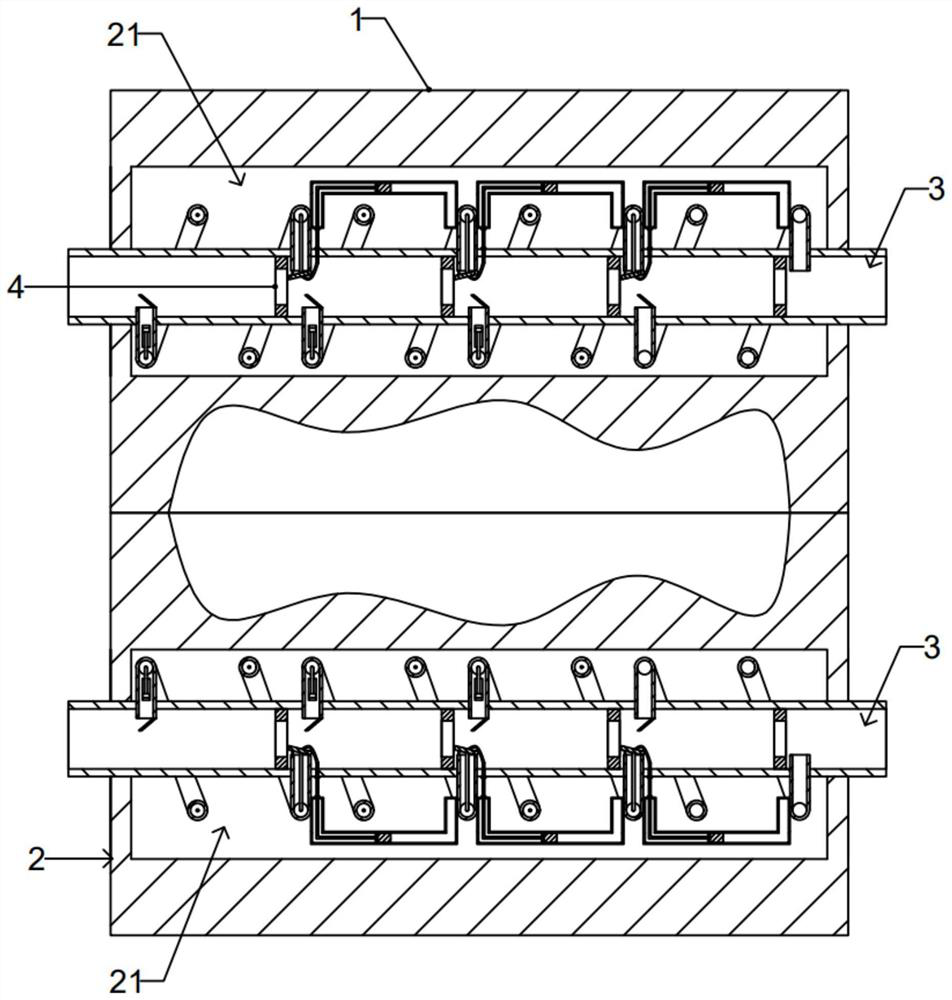

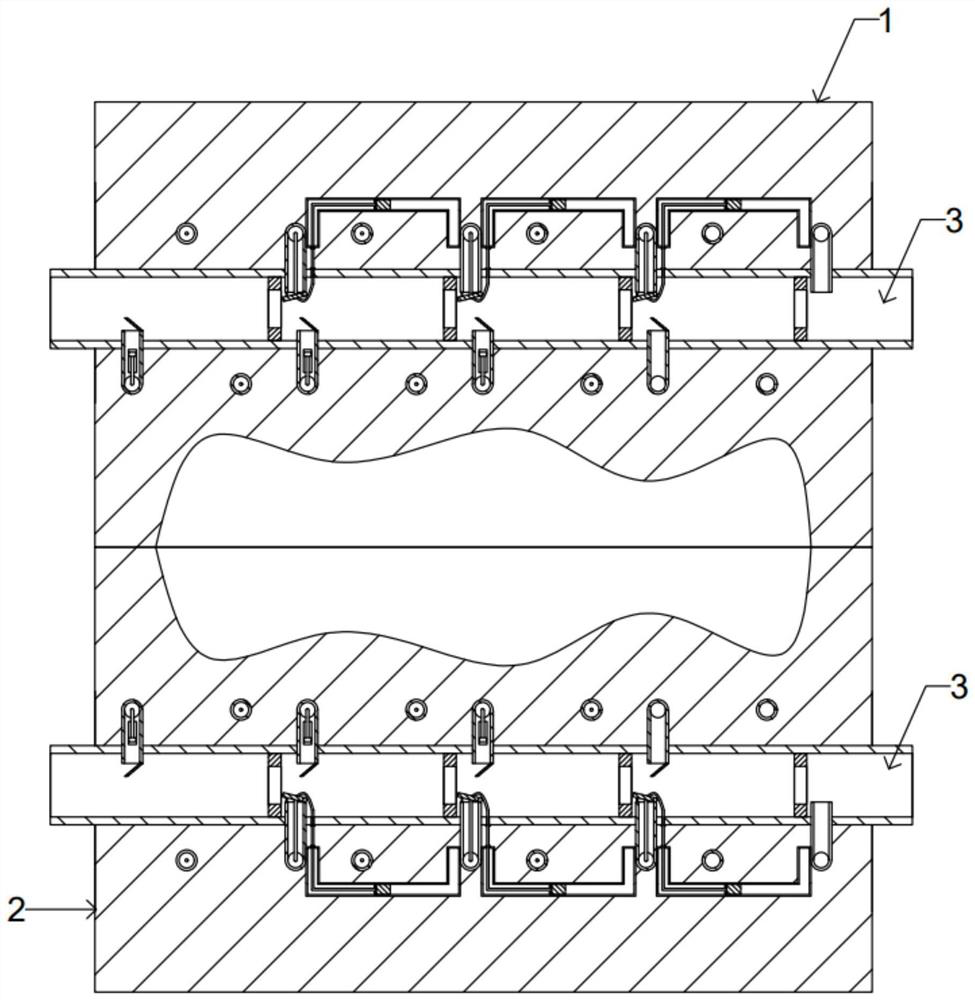

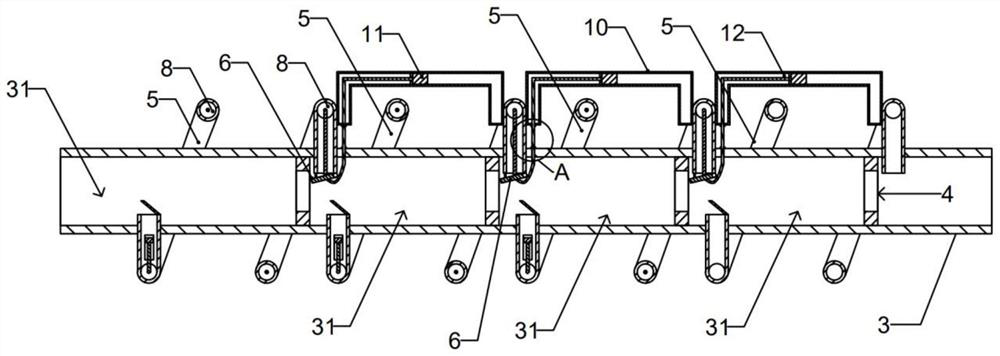

[0037] A rapid cooling injection mold includes a first mold 1 and a second mold 2 that are engaged with each other. The first mold 1 and the second mold 2 are engaged with each other to form a sealed cavity, and the injection molded product is cooled after being heated in the sealed cavity. The first mold 1 and the second mold 2 are provided with cooling pipes 3, and the cooling liquid flows through the cooling pipes 3 to cool the cooling pipes 3, and then the injection molded products are cooled through the cooling pipes 3, and several cooling pipes are arranged at intervals in the cooling pipes 3. part 4, and the cooling part 4 divides the cooling pipe 3 into several connected cooling sections 31, the cooling liquid flows in the cooling pipe 3, and when the cooling liquid flows through the cooling part 4, the cooling part 4 performs secondary cooling on the cooling liquid and absorbs The heat of the cooling liquid keeps the cooling liquid at a lower cooling temperature during...

Embodiment 2

[0048] The difference between the second embodiment and the first embodiment is that the cooling pipeline 3 and the spiral heat exchange tube 5 are embedded in the first mold 1 and the second mold 2, and the cooling pipeline 3 and the spiral heat exchange tube 5 are set in an embedded manner. The cooling pipe 3 and the spiral heat exchange tube 5 are directly in contact with the mold to improve the cooling efficiency of the mold.

[0049] An injection molding system includes a main body of the injection molding system and the above-mentioned rapidly cooling injection mold.

[0050] Working principle: The cooling liquid flows through the cooling pipe 3. When the cooling liquid flows through the cooling part 4, the cooling part 4 performs secondary cooling on the cooling liquid and absorbs the heat of the cooling liquid, so that the cooling liquid keeps flowing in the cooling pipe 3. lower cooling temperature;

[0051] When the temperature of the liquid outlet of the spiral hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com