Semi-transparent IML thin film with textures and processing technology of semi-transparent IML thin film

A film and texture technology, applied in the field of semi-transparent textured IML film and its processing technology, can solve the problems of particulate matter or printing trace optical effect, printing trace optical effect, etc., and achieve high optical display effect, long service life, use flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

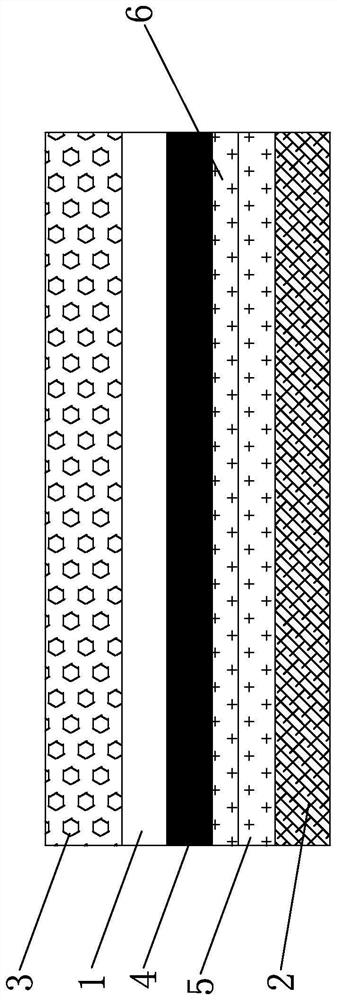

[0023] A semitransparent textured IML film of the present invention, such as figure 1 Shown, have transparent PET film 1 and translucent PET film 2, the preferred thickness of this transparent PET film 1 is 0.05-0.188mm, is provided with UV transfer texture layer 3 on the front side of transparent PET film 1, this UV transfer texture Layer 3 is processed by UV transfer printing equipment. The back of the transparent PET film is provided with a first easy-to-adhesive layer 4. This first easy-to-adhesive layer 4 is an oily adhesive layer, specifically an oily adhesive layer. The bonding agent is applied on the back of the transparent PET film by coating to form an easy bonding layer with a thickness of 3-5um.

[0024] The semi-permeable PET film 2 is a colored PET film, which is formed by co-extruding the color masterbatch and transpa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com