Seat backrest angle adjusting structure with buffering and damping functions

An angle adjustment structure and seat back technology, applied in the direction of movable seats, etc., can solve the problems of seat cover damage, passenger injury, cushion pet injury, etc., and achieve the effect of reducing the turning speed, avoiding damage, and preventing abnormal noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

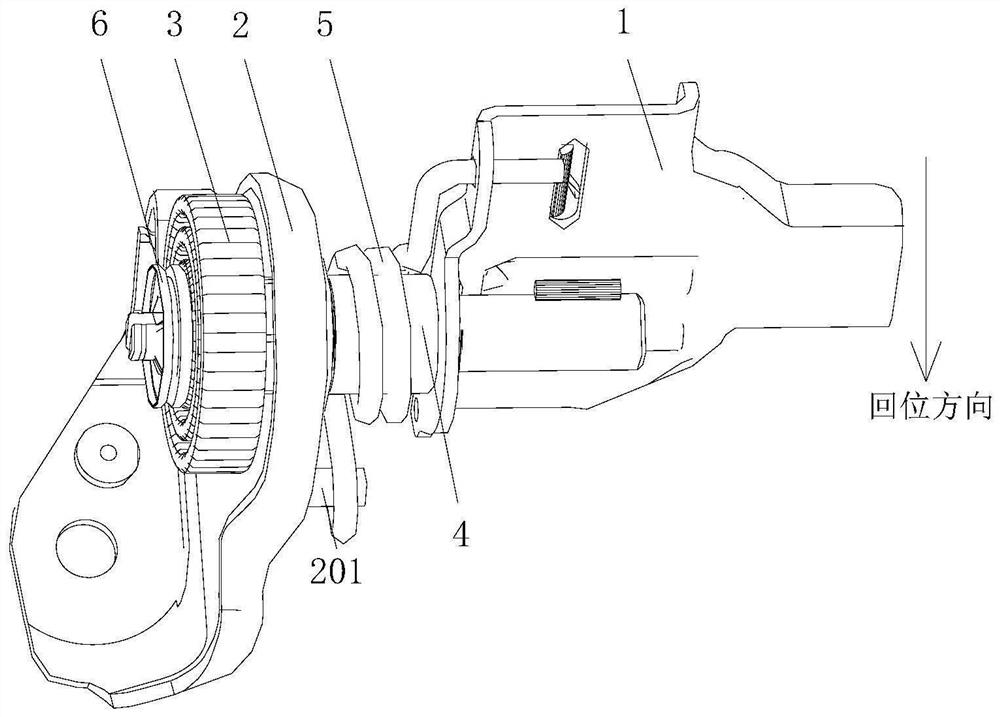

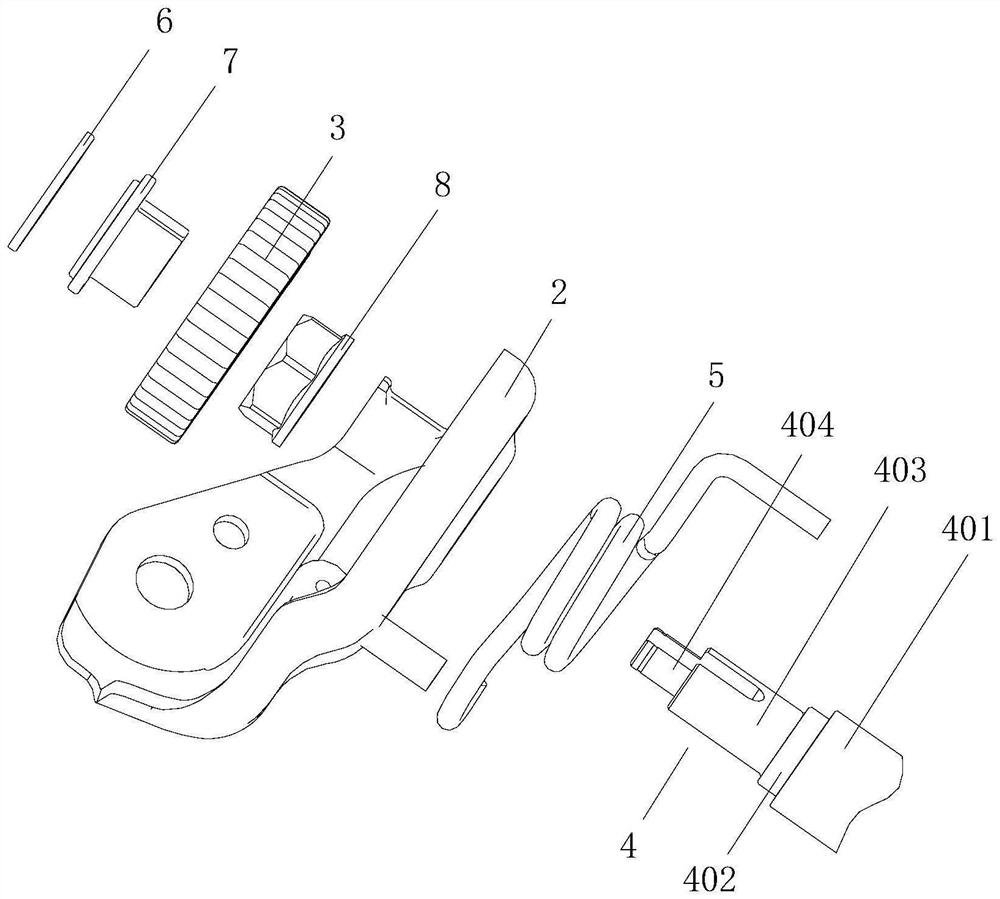

[0016] Such as figure 1 - As shown in -3, a seat back angle adjustment structure with a buffer damping function is mainly composed of a hinge bracket 1 fixed on the backrest and a mounting bracket 2 fixed on the seat cushion.

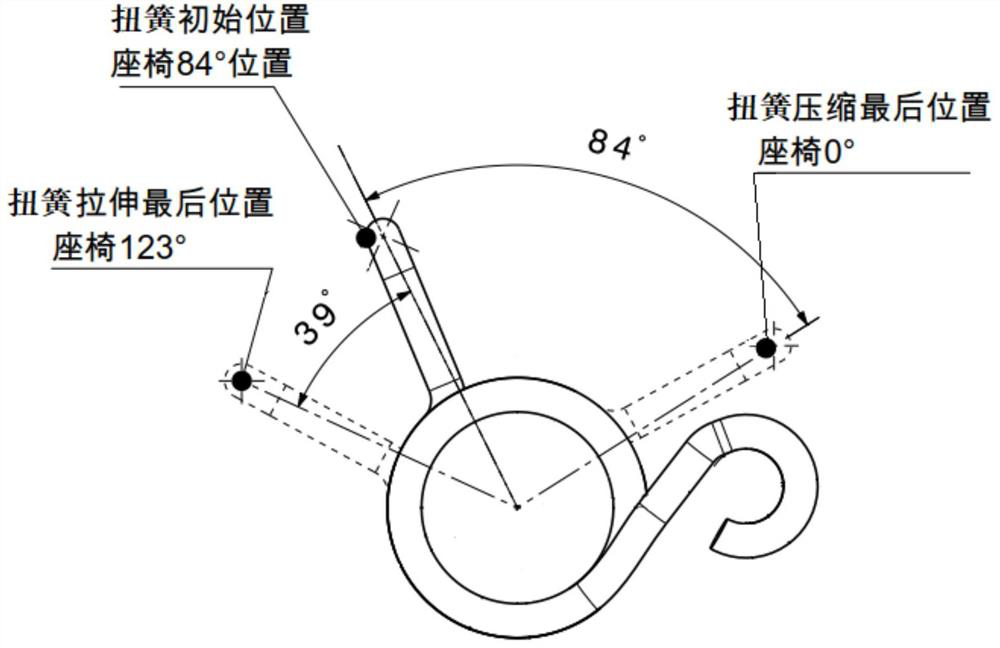

[0017] The hinge bracket 1, the installation bracket 2 and the scroll spring 3 are sequentially set on the backrest shaft 4 from the inside to the outside, the hinge bracket 1 and the backrest shaft 4 are fixed, the installation bracket 2 and the backrest shaft 4 are rotationally matched, and the inner end of the scroll spring 3 Clamped on the backrest shaft 4, the outer end of the scroll spring 3 is hooked on the mounting bracket 2. When the backrest is in use, the scroll spring 3 is compressed and has the torsion to drive the backrest to turn forward.

[0018] Both the mounting bracket 2 and the hinge bracket 1 are stamped from sheet metal parts, and both the mounting bracket 2 and the hinge bracket 1 are provided with reinforcing flanges. Strengthen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com