Fixtures to slow the rate of overturning

A technology of fixing device and turning speed, which is used in transportation and packaging, conveyor objects, furnaces, etc., can solve the problems of too much impact, glass vibration, contact gaps, etc., and achieve the effect of slowing the turning speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

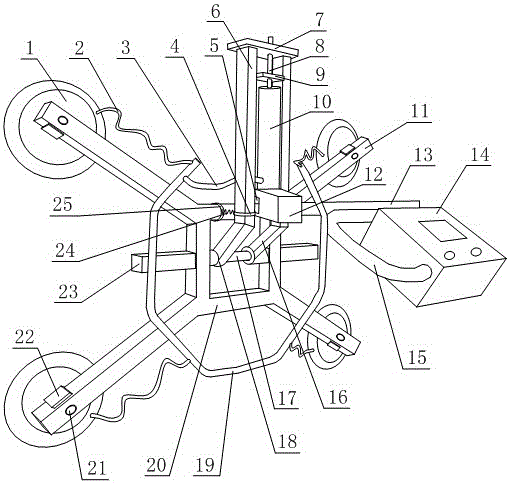

[0013] Such as figure 1As shown, the fixing device for slowing down the overturning speed includes a support frame 20 in a regular quadrilateral structure, the center of the support frame 20 is provided with a through hole, and the outer wall of the support frame 20 is provided with four support plates 11, each The support plates 11 are respectively connected to a corner of the support frame 20 to form an integral structure, the support plates 11 are connected with a suction cup 1, the back side of the suction cup 1 is provided with a fixed frame 22, and the fixed frame 22 is arranged between the suction cup 1 and the support plate 11, The support plate 11 is embedded in the fixed frame 22, and the support plate 11 is provided with a fixing bolt 21, and the fixing bolt 21 passes through the support plate 11, the fixed frame 22 and the suction cup 1 at the same time; the through hole of the support frame 20 is provided with a pin shaft 17. The two ends of the pin shaft 17 are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com