Method for improving reliability of undercarriage system of civil aircraft

A landing gear and reliability technology, which is applied in the field of improving the reliability of the landing gear system of civil aviation airliners, can solve the problems of nail wear and affect the continuity of sensor lines, etc., so as to reduce the wrong replacement of parts, reduce the wear speed, and prolong the working time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A method for improving the reliability of the landing gear system of a civil aviation passenger aircraft according to the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

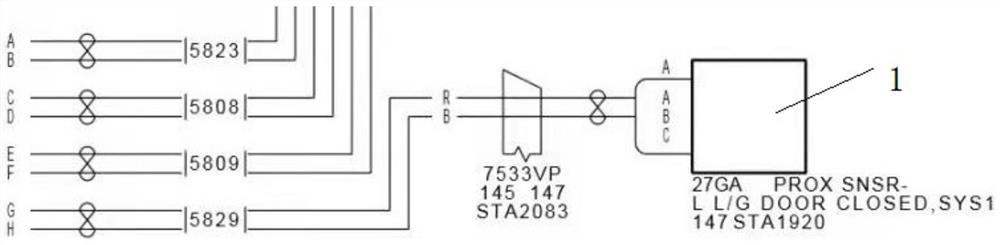

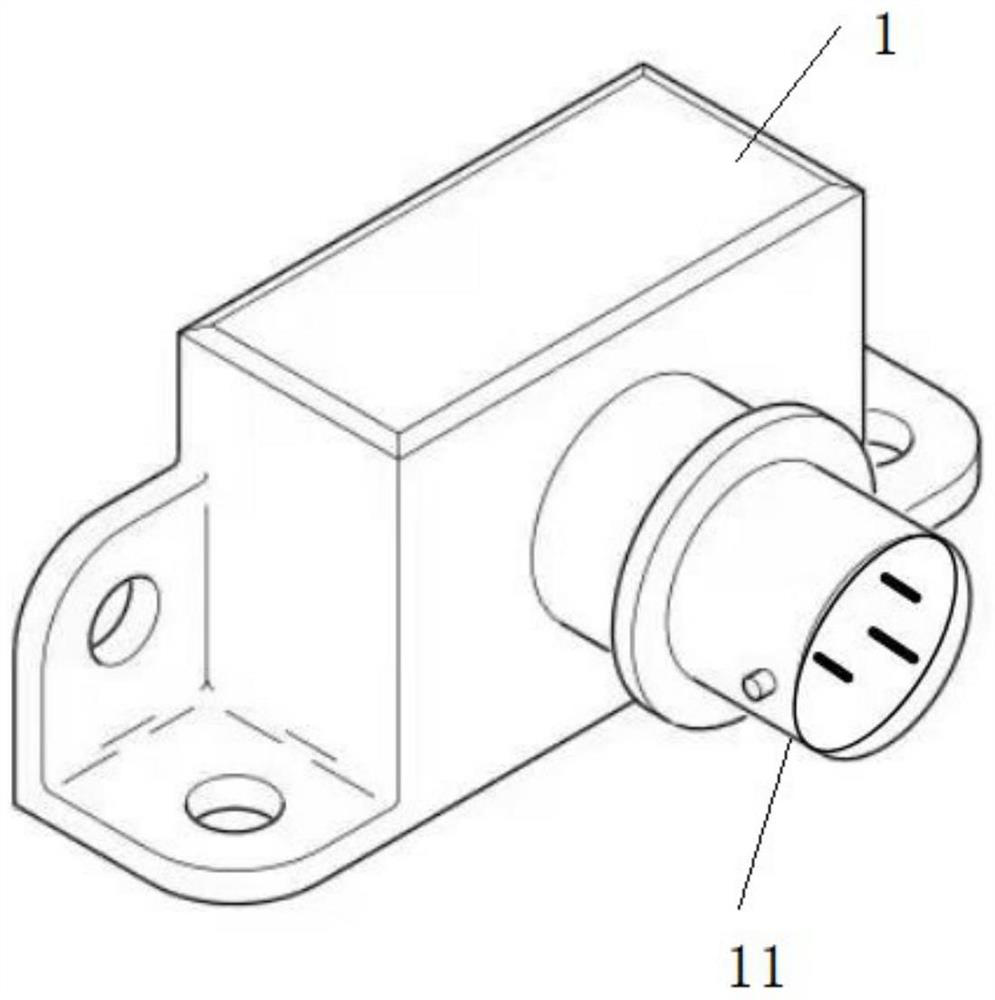

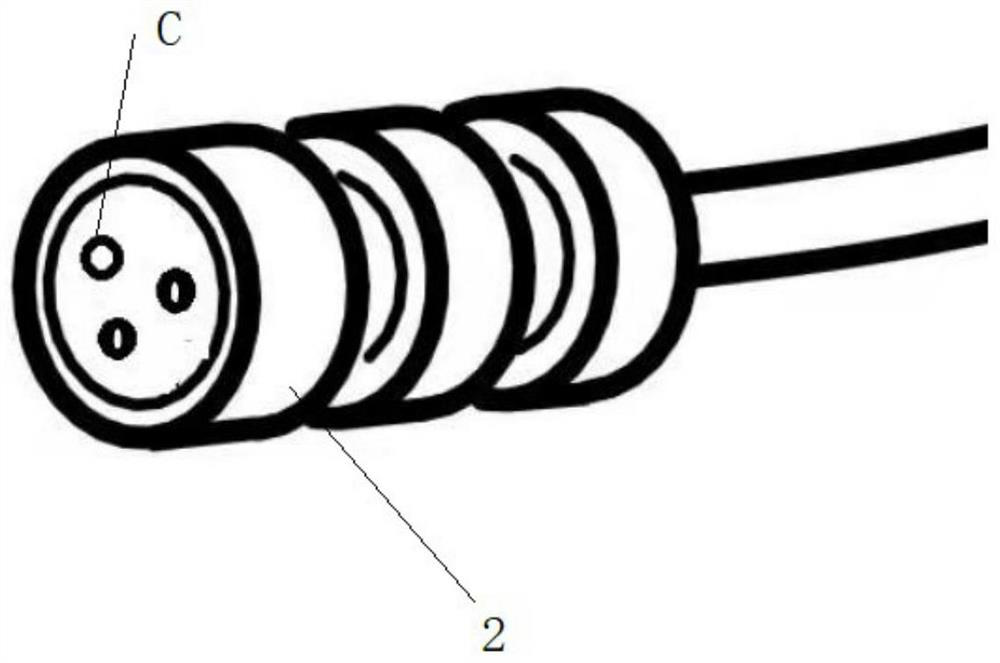

[0030] The model involved in the following embodiments is the Airbus A320. The structural diagrams of the proximity sensor plug and the docking plug of the Airbus A320 landing gear system are as follows: figure 2 , 3 shown. For this model, we have taken the following measures to improve the reliability of its landing gear system:

[0031] Hardware: reinstall image 3 The female pin at the C position of the butt plug, so that image 3 mating plugs in and figure 2 The connection of the proximity sensor plugs in the aircraft can keep them in a better balance during the vibration process of the aircraft, thereby effectively reducing the wear speed of the insertion pins, prolonging the working time of the proximity senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com