Fabricated metal support foundation for 330kV power transmission line project and construction method of fabricated metal support foundation

A technology for metal supports and transmission lines, applied in infrastructure engineering, construction, etc., can solve the problems of long working hours, tower assembly, and tight lay-out time, and achieve the effects of convenient disassembly and transportation, shortened construction period, and clear force transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the above objects, features, and advantages of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

[0036] The present invention will be further described below with reference to the accompanying drawings.

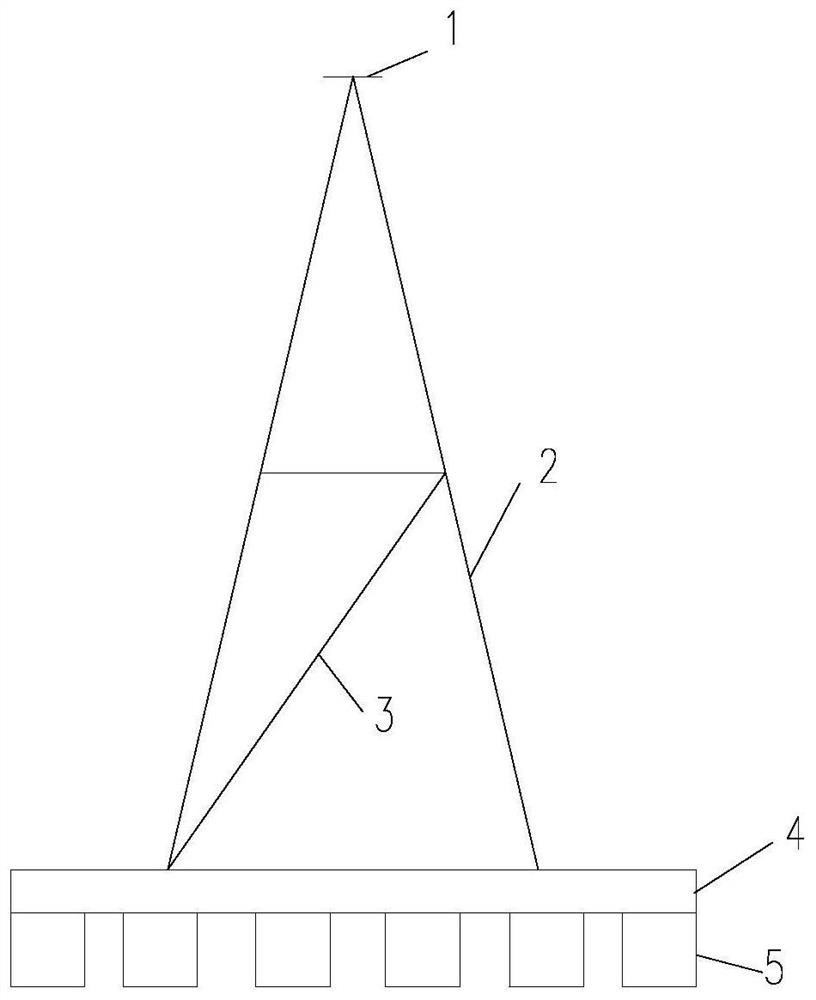

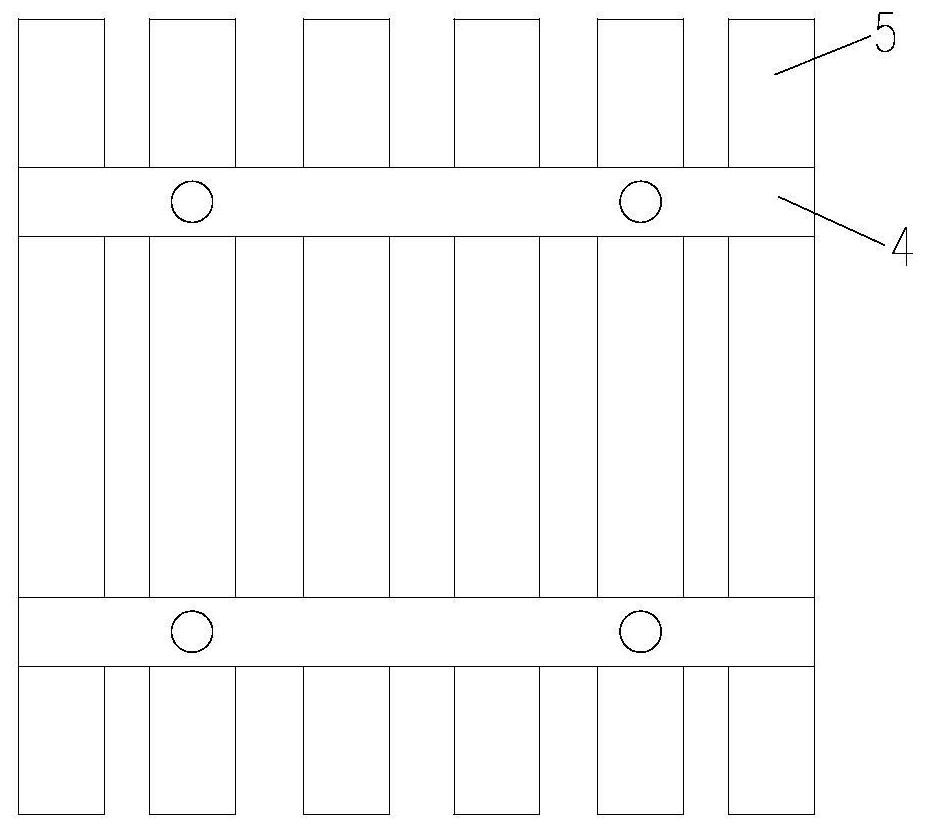

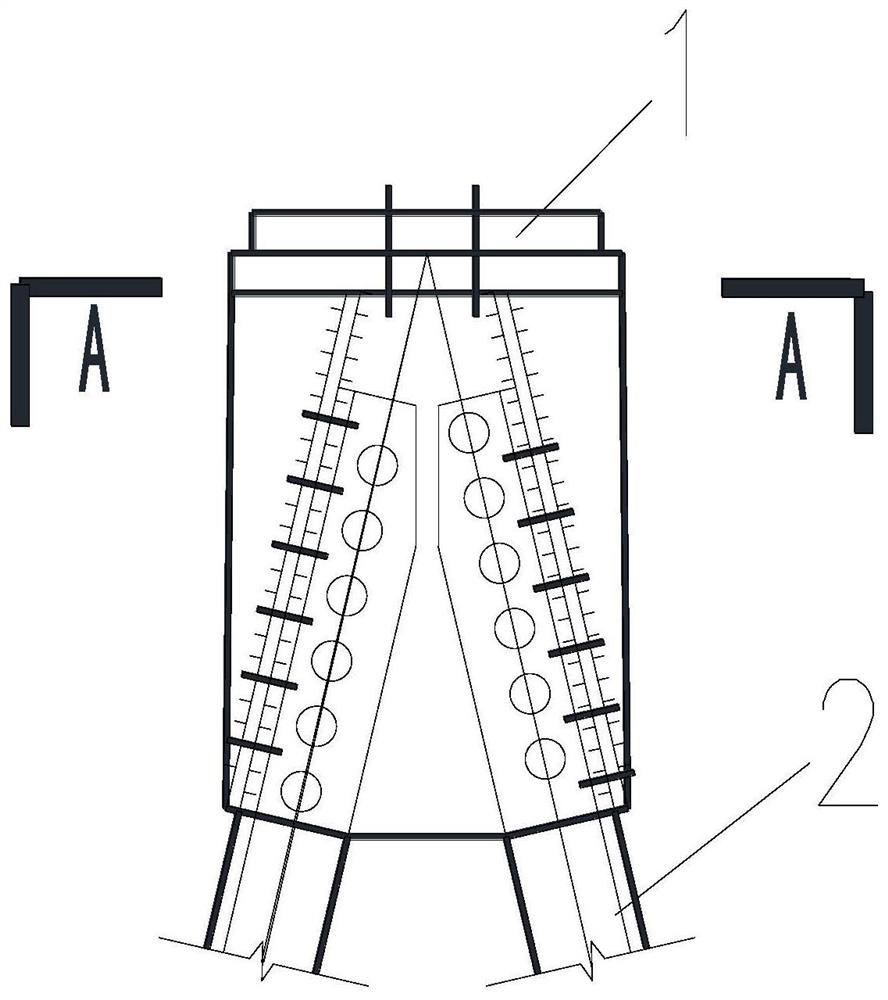

[0037] Referring to FIG. 1, FIG. 1 (a) An assembled metal stent foundation for a 330kV transmission line engineering is a steel structure. The whole is in a four-priced cone, including the base bottom plate 5 and the beam 4 connected to the base bottom plate 5, The base bottom plate 5 and the beam 4 are connected by a bolt; the metal bracket 2 is connected to the metal bracket 2 on the beam 4; the metal bracket 2 is provided with four, and the four metal brackets 2 are located on the four ridges of the tetraps, and the bracket is connected by the bracket. Support, the lower end of the bracket diagonal support 3 connects the beam 4, the upper end of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap