Fabricated building outer envelope wall body system

A prefabricated, wall technology, applied in the direction of building, building structure, covering/lining, etc., can solve the problems of the overall water tightness, poor air tightness of the building, cracking of the outer wall of the building, etc., to avoid stress The effect of gathering, enhancing breathability, increasing water tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

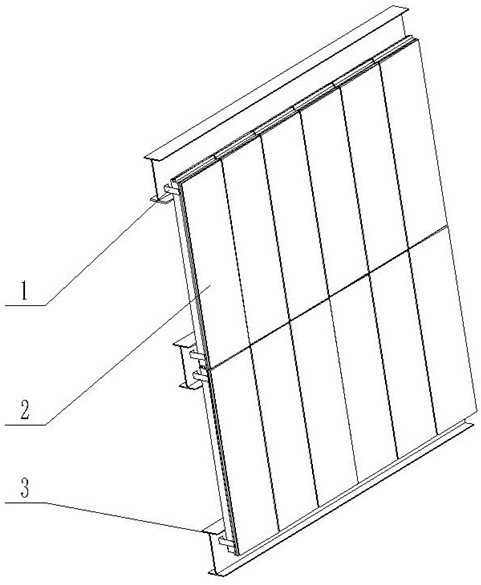

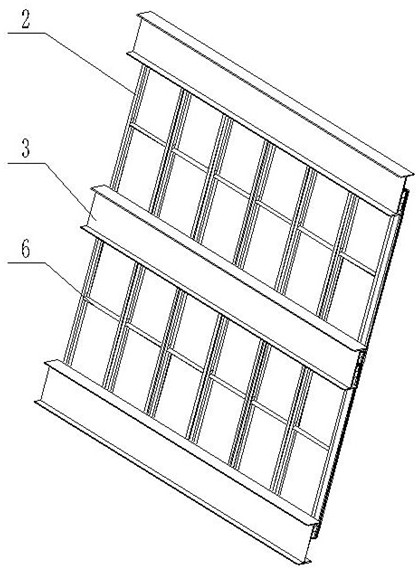

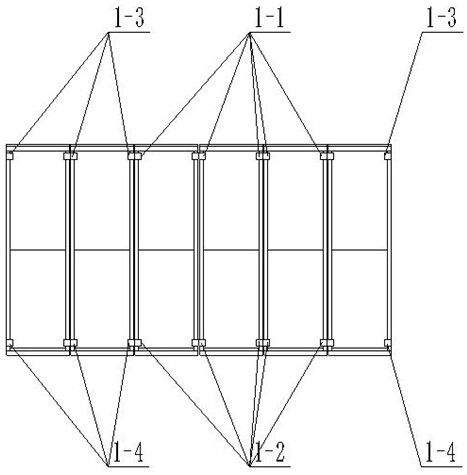

[0024] Such as Figure 1-3 Shown is a prefabricated building enclosure wall system, the system includes a connecting bracket 1 and a prefabricated wall 2; it is connected and fixed to the whole building through the connecting bracket. In this embodiment, the external protective wall system of the prefabricated building is connected to the I-beam 3 through the connecting bracket; one end of the three prefabricated walls is fixedly connected to the whole building through the fixing bracket 1-1, and the other end is connected vertically The movable bracket 1-2 is fixedly connected with the overall building; one end of other fabricated walls is connected with the overall building through the horizontal movable bracket 1-3, and the other end is connected with the overall building through the bidirectional movable bracket 1-4.

[0025] The connection bracket is divided into a fixed bracket, a vertical movable bracket, a horizontal movable bracket and a two-way movable bracket. Such...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap