Semi-solid formed climbing frame guide seat equipment

A semi-solid forming and guide seat technology, which is applied in the field of climbing frames, can solve the problems of broken guide seats, insufficient stability and tilting of climbing frame guide seats, and achieve the effect of preventing bending and breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

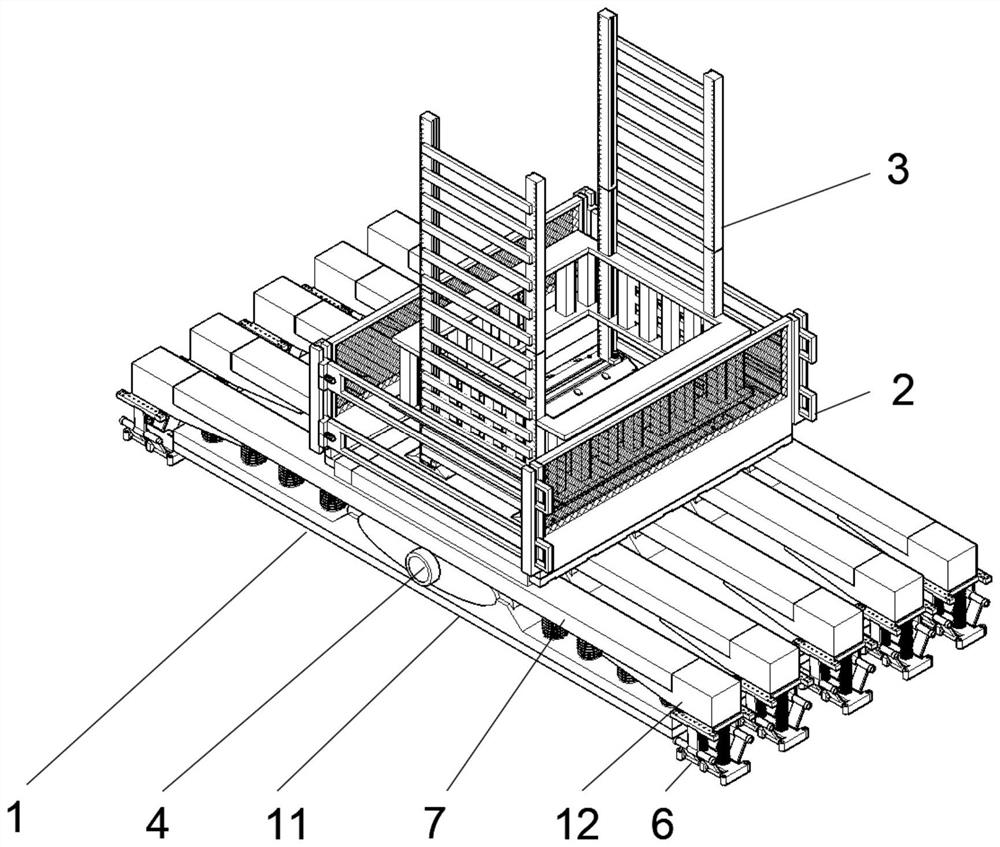

[0052] see figure 1 and Figure 8 , an embodiment provided by the present invention: a semi-solid formed climbing frame guide seat equipment, including a support protection control mechanism 1, a reinforcement support part 2 and a sliding device 3, and the reinforcement support part 2 is fixedly installed on the support protection control mechanism 1 In the middle of the upper end, the sliding device 3 is fixedly installed at the inner middle end of the reinforcement support part 2;

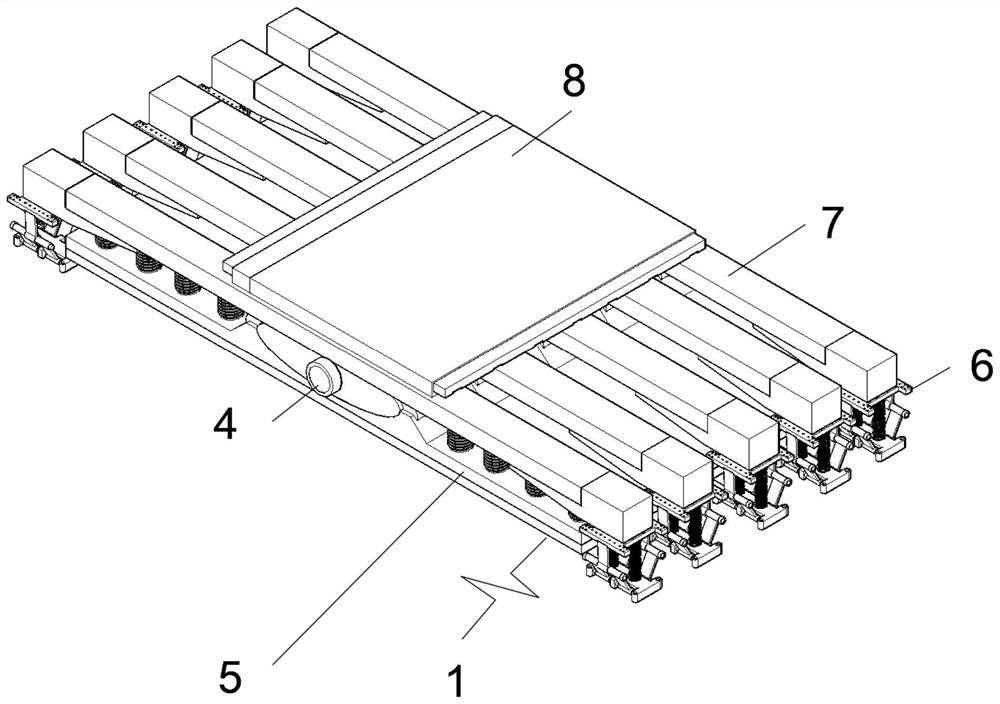

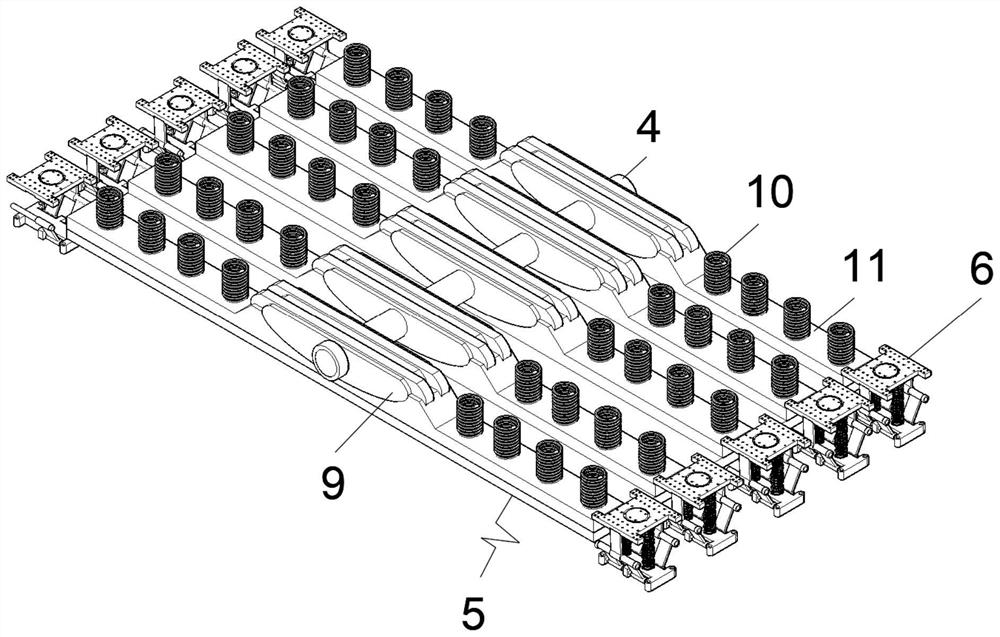

[0053] see figure 2 , the support protection control mechanism 1 includes a rotating bolt 4, a support fixed base 5, a buffer adjustment control device 6, a support adjustment plate 7 and an installation and processing base 8, and there are five support adjustment plates 7, and the support adjustment plate 7 passes through the rotation bolt 4 The rotation is installed on the upper end of the support fixed base 5, the installation and processing base 8 is fixedly installed on the middle part of...

Embodiment 2

[0066] On the basis of Example 1, such as Figure 15-16 As shown, the bottom end of the support reinforcement frame 35 is evenly fixed with a plug-in fixing column 36 , which is tapered and is made of stainless steel.

[0067] When implementing this embodiment, since the bottom end of the support reinforcement frame 35 is evenly fixed with the plug-in fixed column 36, the plug-in fixed column 36 is tapered, and the material of the plug-in fixed column 36 is stainless steel, so it is strengthened by supporting The frame 35 can stabilize the outermost support adjustment plate 7 during use, thereby ensuring a stable support to the bottom of the device and making it safer and more stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com