Wind power blade, manufacturing method thereof and wind power generator

A technology of wind turbines and wind turbine blades, which is applied to wind turbines, wind power generation, engines, etc., can solve problems such as fracture, easy deformation, and impact on the safety of wind turbines, and achieve reduced diameter, weight, and overall reduction. The effect of machine head weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention is further illustrated below by means of examples, but the present invention is not therefore limited to the scope of the following examples.

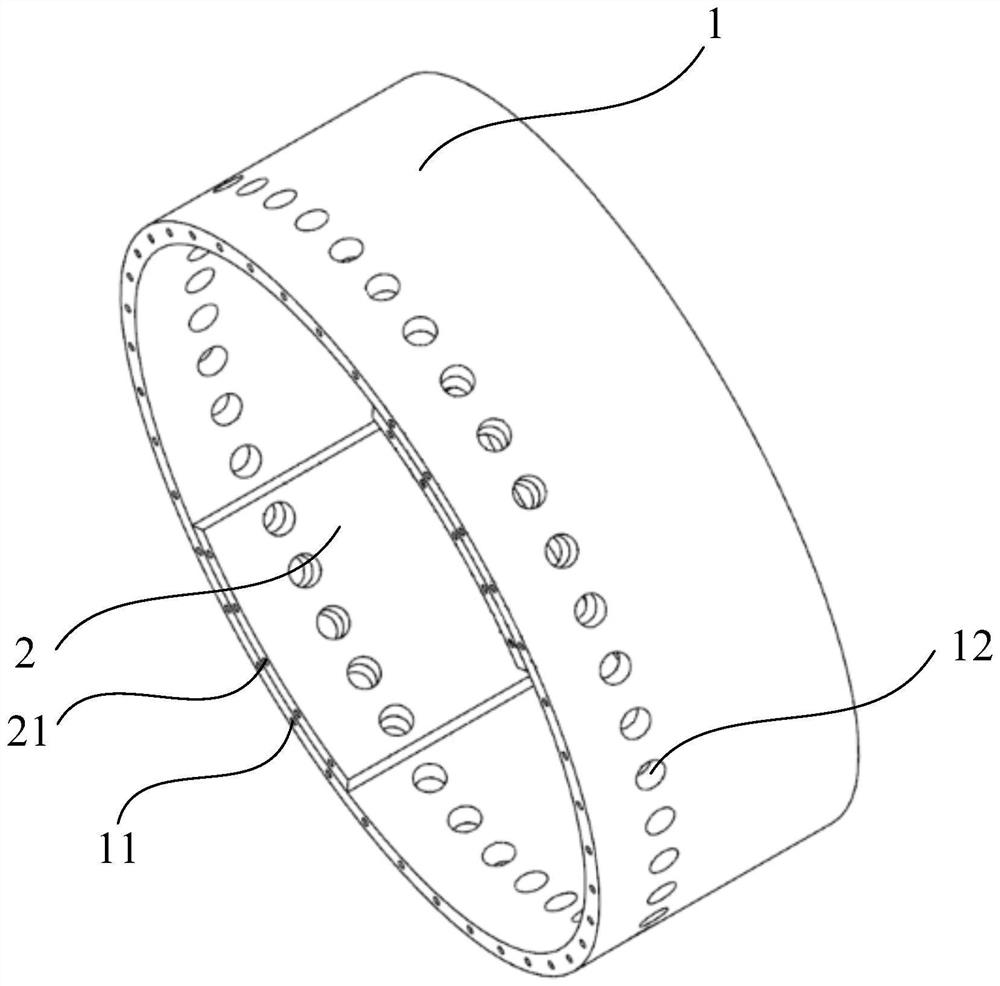

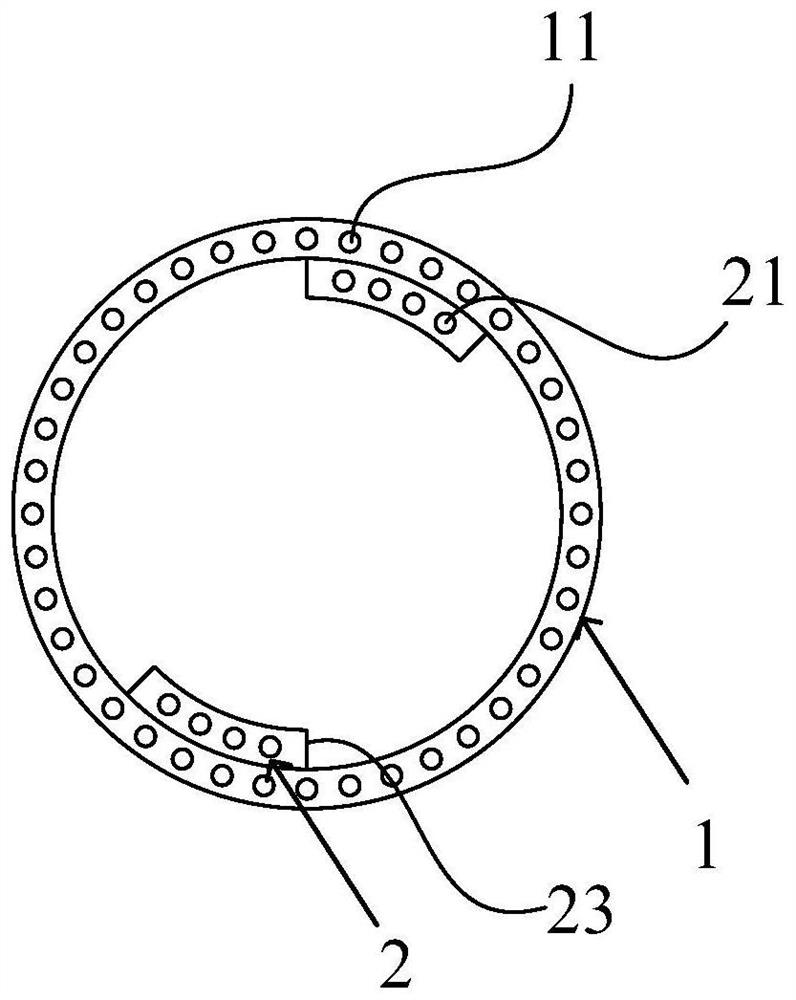

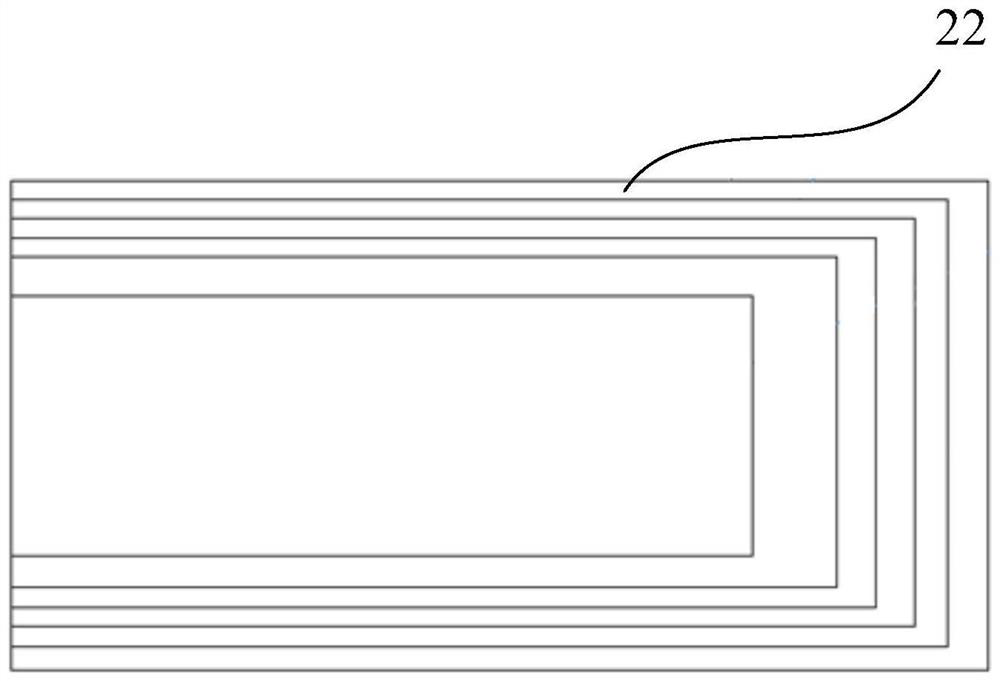

[0057] An embodiment of the present invention provides a wind turbine blade, such as figure 1 , figure 2 , Figure 4 and Figure 5 shown. The wind turbine blade includes a blade root 1 , first connecting holes 11 are opened on the end face of the blade root 1 connected to the hub of the wind generator, and the first connecting holes 11 are distributed along the circumferential direction of the blade root 1 . The outer peripheral surface of the blade root 1 is provided with a cylindrical hole 12 communicating with the first connecting hole 11, and the cylindrical hole 12 is provided correspondingly to the first connecting hole 11. shaped pieces. The first connecting hole 11 is used for installing the first connecting piece, one end of the first connecting piece is connected with the cylindrical piece, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com