Front dumper double-seal hydraulic oil cylinder

A technology for sealing hydraulic pressure and dump trucks, which is applied in the field of hydraulic cylinder sealing, which can solve the problems of inconvenient replacement of sealing rings and achieve the effect of ensuring pressure difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

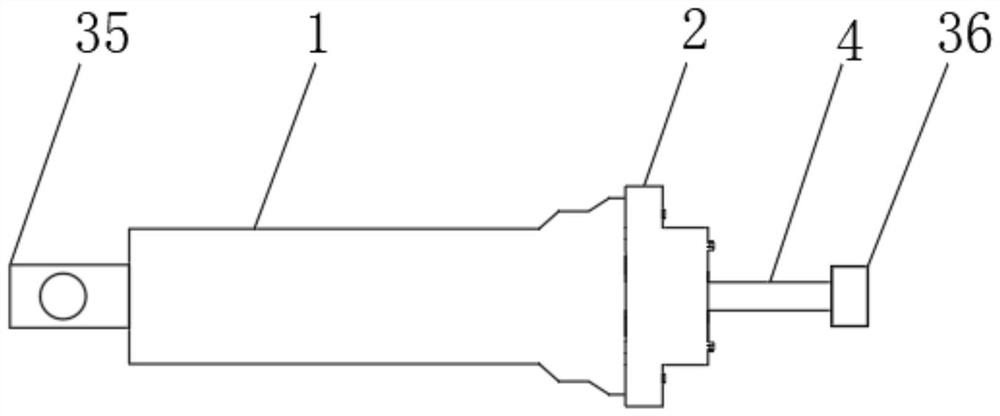

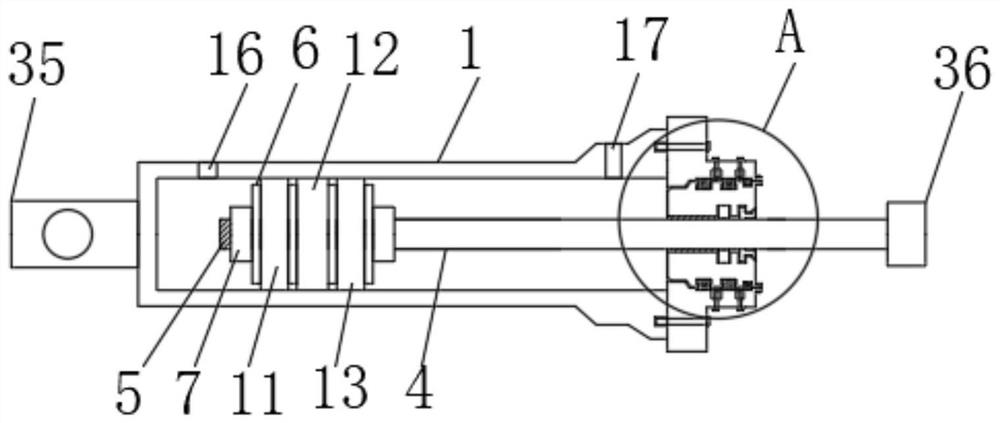

[0030] see Figure 1 to Figure 5 , the present invention provides a technical solution: a front-mounted dump truck double-channel sealed hydraulic cylinder, including a hydraulic cylinder block 1 and a cylinder head 2, the cylinder head 2 is installed on the right end of the hydraulic cylinder block 1, and the cylinder head 2 is sleeved with a guide sleeve 3, and the interior of the hydraulic cylinder 1 is provided with a piston rod 4 that penetrates the guide sleeve 3 and extends to the cylinder head 2;

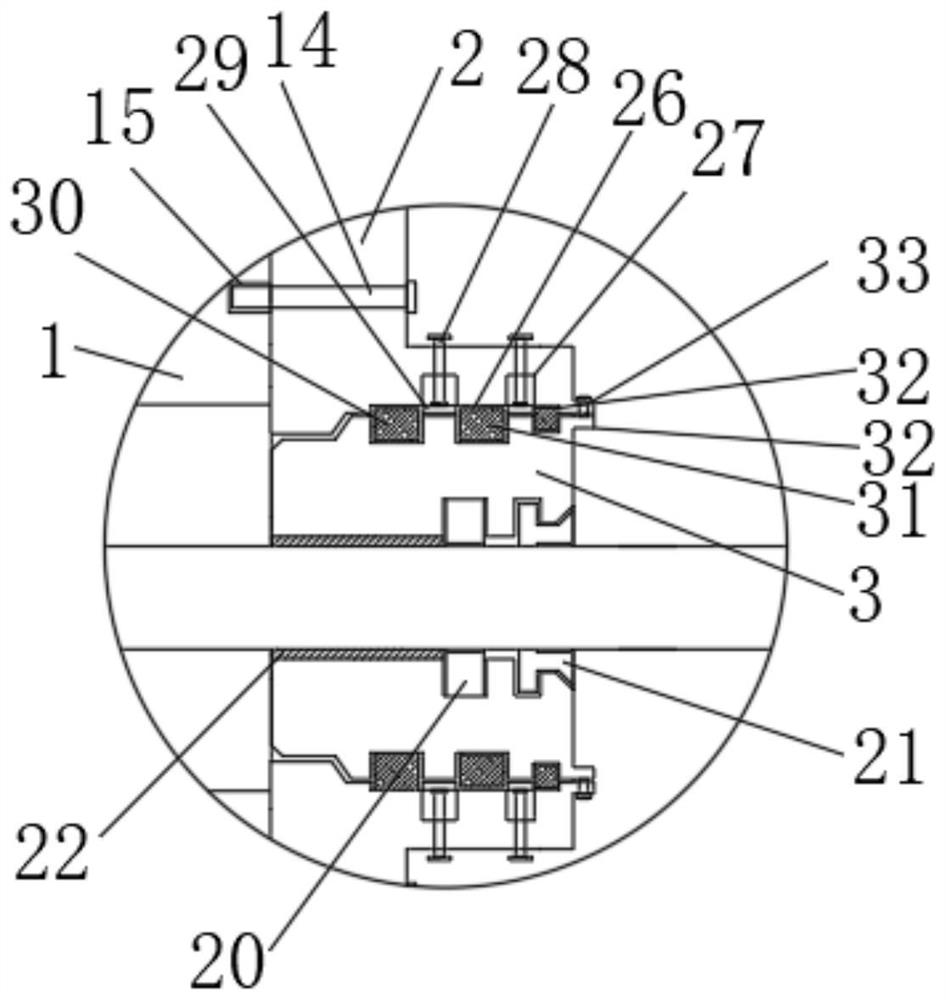

[0031] The inner wall of the guide sleeve 3 is sequentially provided with a guide sleeve first groove 23, a guide sleeve second groove 24 and a guide sleeve third groove 25 from left to right;

[0032] The inner top wall and inner bottom wall of the cylinder head 2 are symmetrically provided with rectangular gaps 26, and the outer end of each rectangular gap 26 is provided with two extension grooves 27, and the top and bottom of the guide sleeve 3 are screwed with two groove...

Embodiment 2

[0040] Embodiment two, the difference with embodiment one is:

[0041] Specifically, the left side of the hydraulic cylinder block 1 is provided with a mounting seat 35, and the right end of the piston rod 4 is provided with a connecting seat 36. The mounting seat 35 provided is used to realize the installation work of the hydraulic cylinder block 1. The connecting seat The setting of 36 is used to connect the parts that need to be telescopic.

[0042] Working principle: when replacing the first sealing ring 30 of the cylinder head, the second sealing ring 31 of the cylinder head, and the third sealing ring 32 of the cylinder head on the guide sleeve 2, Only need to unscrew some locking bolts 14, and unscrew the threaded rods and nuts on the first flange plate 33 and the second flange plate 34, then by manually rotating the threaded column 28, utilize the threaded column 28 and the cylinder head 2 Screw connection, the position of spacer 29 can be adjusted, spacer 29 is moved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com