Differential planetary roller screw pair, assembly tool and assembly process

A technology of planetary roller and assembly process, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problem of rare differential planetary roller screw pair, etc., to achieve low tooling cost, tooling Simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

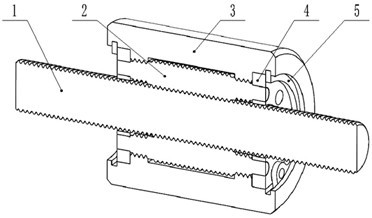

[0039] Such as figure 1 As shown, the main structure of the differential planetary roller screw pair includes a screw 1, a roller 2, a nut 3, a cage 4, and a retaining ring 5. Several rollers 2 are installed between the lead screw 1 and the nut 3, and the rollers 2 are evenly distributed around the lead screw through the cage 4. The circlip 5 is clamped at both ends of the nut to limit the axial movement of the roller 2 and the cage 4 .

[0040] Lead screw 1 can be made into single thread or multi-thread form, except for screw thread section, other parts can be designed according to functional requirements. The figure shows only the threaded section.

[0041] The roller 2 is divided into five sections, and the middle three sections are annular threads, and the thread diameter of the most middle section is large, and the thread diameters on both sides are small. The two outermost sections are designed as unthreaded ends for cooperating with the cage 4 .

[0042] The nut 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com