Anti-blocking boiler coal feeding automatic weighing device

An automatic weighing device and anti-clogging technology, which is used in automatic feeding/discharging weighing equipment, measuring devices, weighing and other directions, and can solve problems such as material blockage, damage to the shielding plate, and inconvenient outlet pipe shielding. , to achieve the effect of convenient stirring, convenient fixing and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

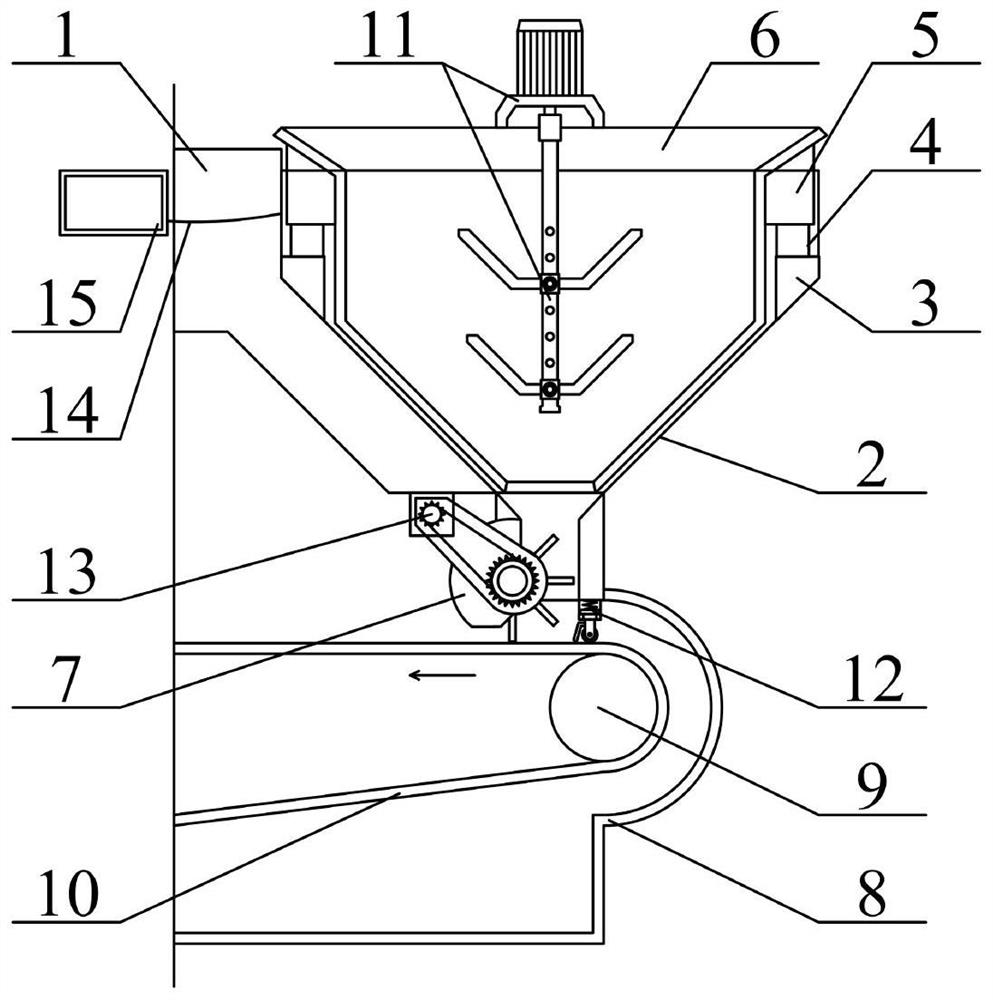

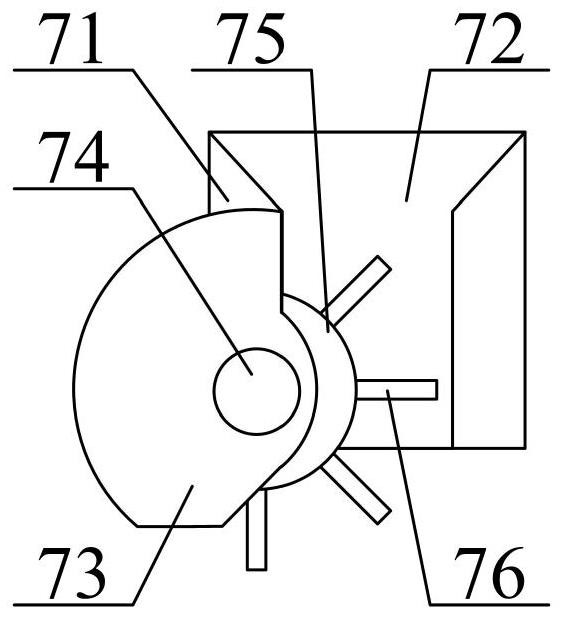

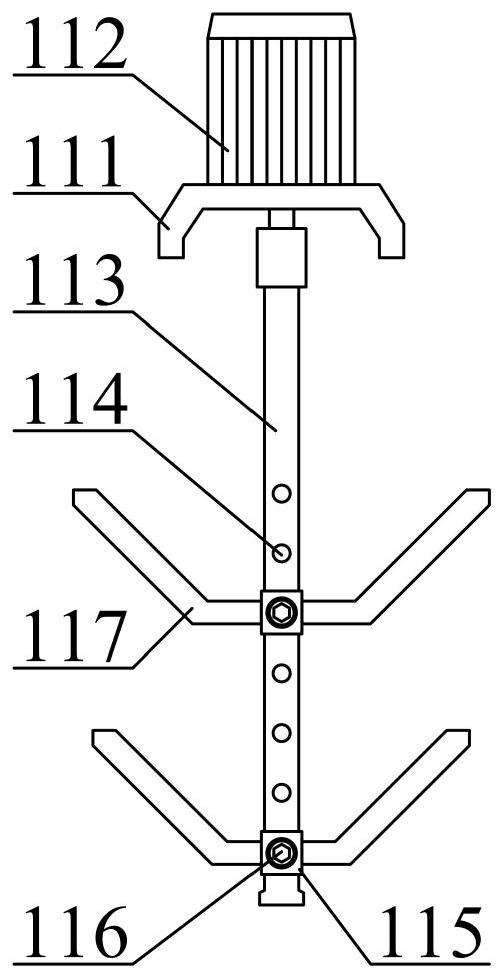

[0040] as attached figure 1 And attached figure 2 shown

[0041]The invention provides an anti-clogging boiler coal feeding automatic weighing device, which includes a boiler body 1, a reinforced support plate 2, a bottom fixing seat 3, a weighing sensor 4, an upper side fixing seat 5, a new media hopper 6, and material positioning Lead-out frame structure 7, bottom outer frame 8, conveying roller 9, conveyor belt 10, adjustable anti-blocking stirring device 11, top-tightening protective frame structure 12, transmission brake frame structure 13, power cord 14 and display screen 15, the The reinforcement support plate 2 bolts are installed on the right side of the boiler body 1; the bottom fixing seat 3 is welded on the left and right sides of the upper inner wall of the reinforcement support plate 2; the load cell 4 bolts are installed on the bottom fixing seat 3 The upper part; the upper fixing seat 5 is placed on the upper part of the load cell 4; the new media bucket 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com