Method for starting supply of molten steel

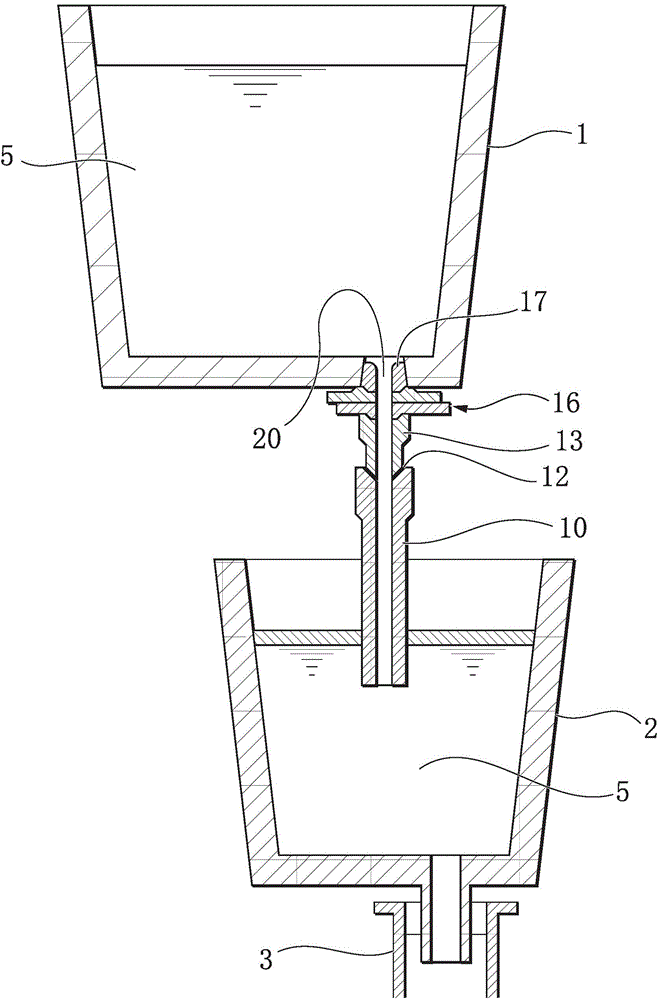

A technology of molten steel and long nozzles, applied in the direction of manufacturing tools, casting melt containers, casting equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Table 1 shows a list of the results of tests conducted to verify the effects of the present invention. The frequency of occurrence of blockage in the table and whether it can be adopted in an actual machine use Comparative Example 1 as a comparison object. Regarding the occurrence frequency of occlusion, those that were improved compared to Comparative Example 1 were set as "good", those that were the same as those of Comparative Example 1 were set as "medium", and those that were worse than those of Comparative Example 1 were set as "poor". ". In addition, regarding the availability of actual machine adoption, the case of usability was set as "good", the case of usable but worse than Comparative Example 1 was set as "medium", and the case of not usability was set as "poor".

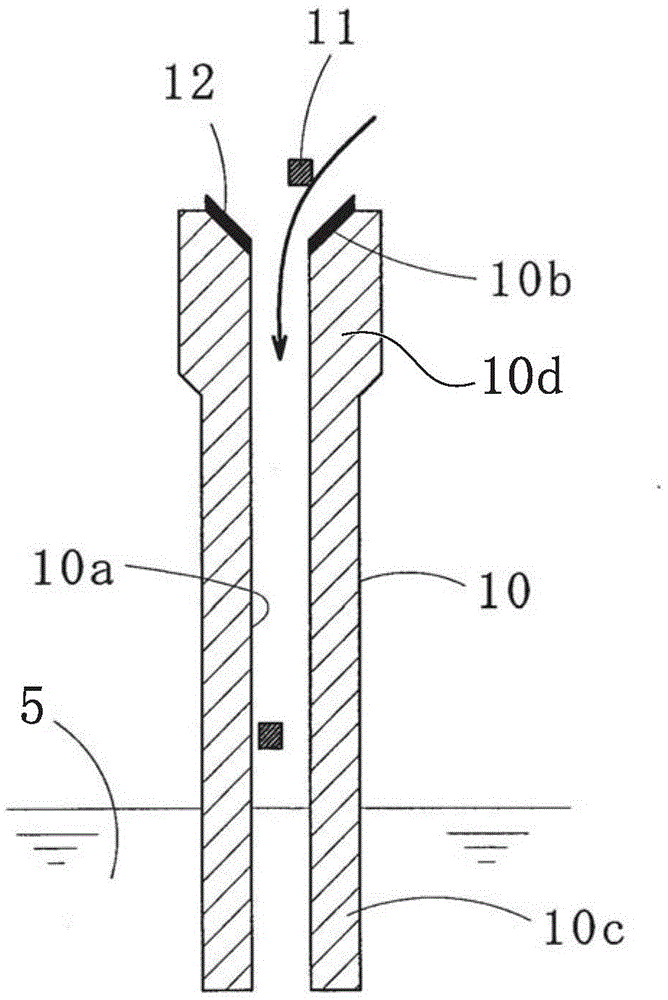

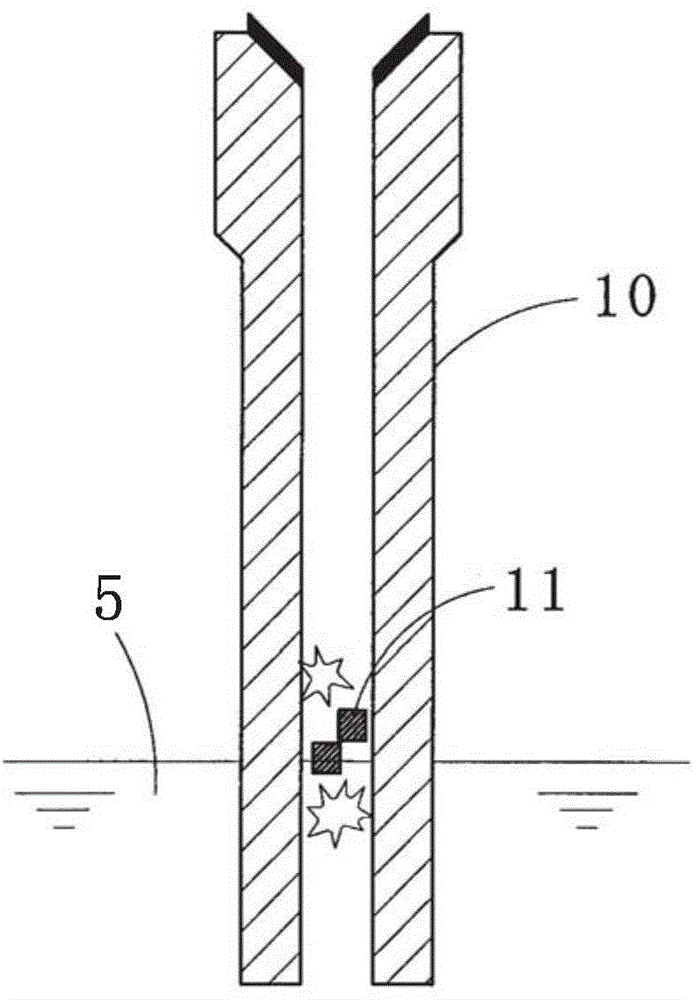

[0074] As the shroud 10, a straight pipe type with an inner diameter of 100 mm and a length of 1.5 m was used. However, only Comparative Example 1 used the shroud 10 in which the inner diameter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com