Method for detecting faults of fuel supply system of gas turbine

A fuel supply system and gas turbine technology, applied in gas turbine engine testing, jet engine testing, etc., can solve problems such as high working pressure, fire unit, fuel system failure, etc., and achieve the effect of a real-time detection method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in more detail below in conjunction with accompanying drawing example:

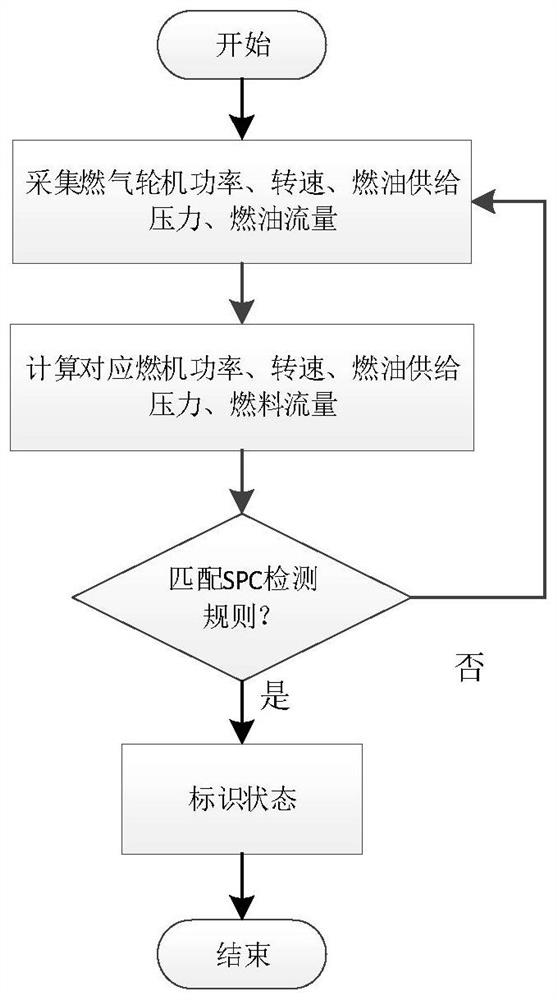

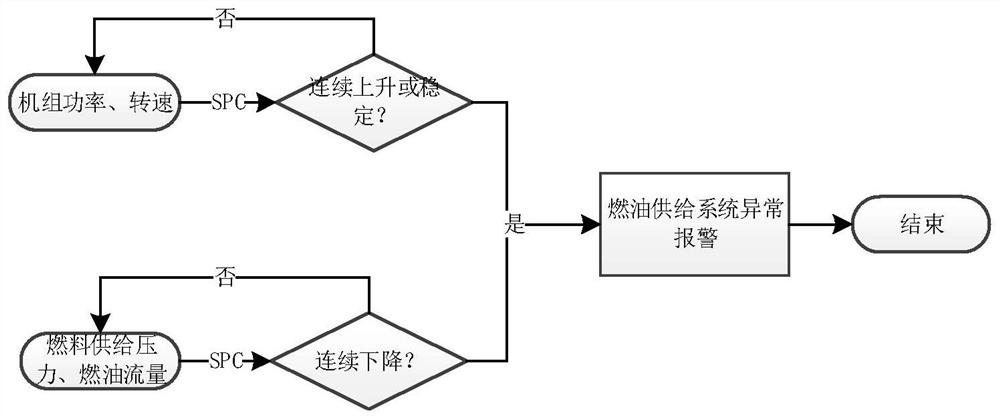

[0024] combine Figure 1-3 , the implementation of the present invention comprises the following steps:

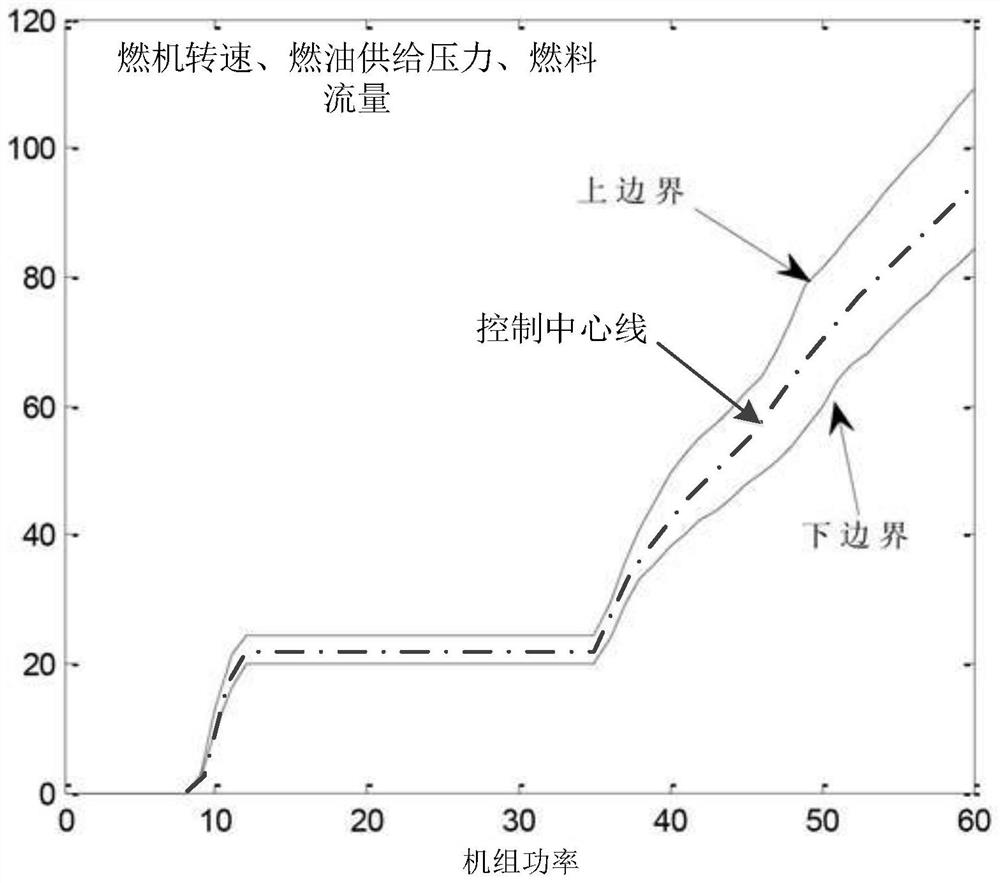

[0025] Establish the power, speed, fuel supply pressure, and fuel flow curves of each working condition under the normal state of the fuel system, and construct the upper boundary, lower boundary and control center line.

[0026] Select the fuel system parameters when the gas turbine is running, and use the historical data of the gas turbine to establish the normal operating power, speed, fuel supply pressure, fuel flow curve, including the upper boundary, lower boundary and control center line.

[0027] The control center line is the average value of the historical normal operation process curve, the upper boundary is the control center line plus n times the standard deviation based on historical data statistics, and the lower boundary is the control center ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com