Pitch loading cabinet and control system

A pitch system and controller technology, applied in electrical program control, program control in sequence/logic controllers, wind power generation, etc., can solve the problems of non-programmable simulation of torque command, immobility, high power consumption, etc. , to achieve the effect of mobility, miniaturization, and rapid torque control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

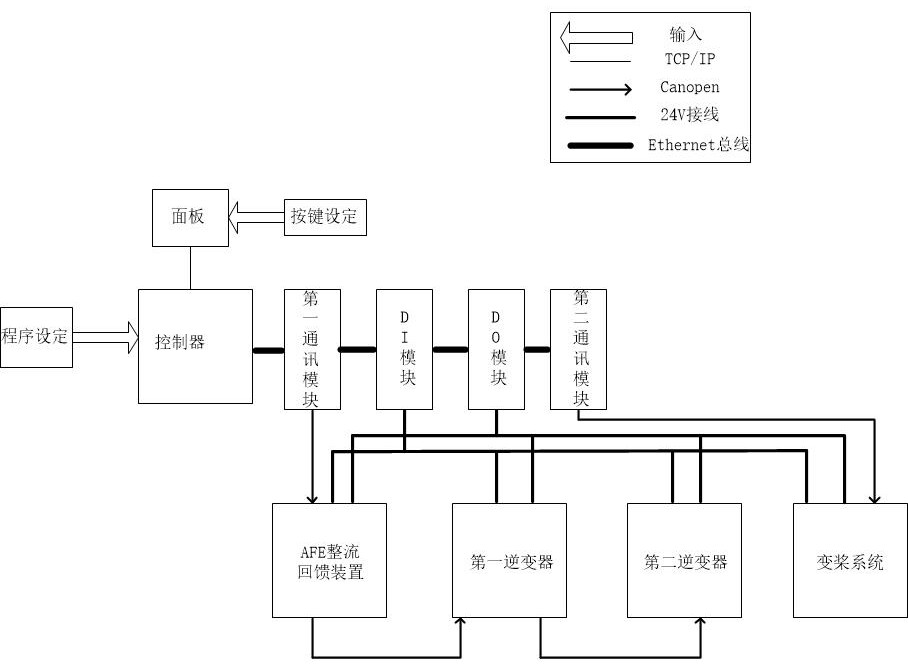

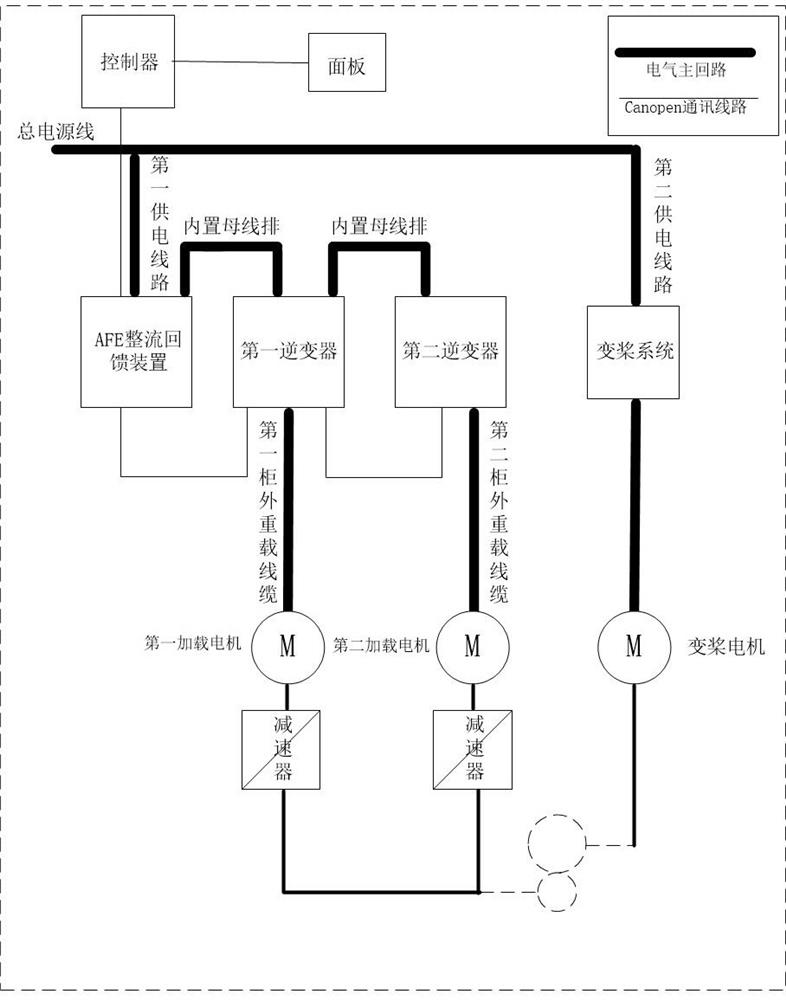

[0045] Embodiment 1: a pitch loading cabinet, such as figure 1 As shown, it includes a controller, an AFE rectifier feedback device, an inverter, a loading motor and an electrical main circuit; the electrical main circuit includes a first power supply line, a second power supply line, a main power line, and a first heavy-duty line outside the cabinet The first power supply line and the second power supply line are connected in parallel, and after the parallel connection, they are connected to the main power line, and a common main power line is used to obtain electricity; the first power supply line is connected to the AFE rectifier feedback device. The AFE rectifier feedback device is connected to the first inverter through the first built-in bus bar, and the first inverter is connected to the second inverter through the second built-in bus bar; The load cable is connected to the first load motor, and the second inverter is connected to the second load motor through the heavy...

Embodiment 2

[0047] Embodiment 2: On the basis of Embodiment 1, the controller, the AFE rectifier feedback device, the first inverter and the second inverter use CANOPEN networking to connect and communicate.

Embodiment 3

[0048] Embodiment 3: On the basis of Embodiment 1, the AFE rectifier feedback device and the inverter both use a book-like structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com