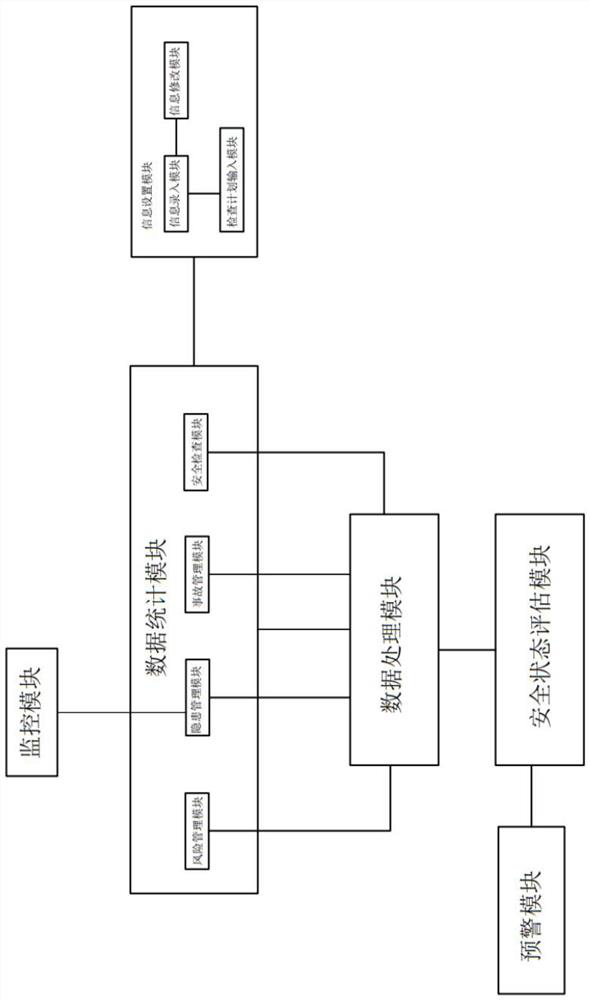

Enterprise safety condition instant evaluation management system

A management system and enterprise technology, applied in the field of safety management, can solve problems such as untimely evaluation of enterprise safety status, hidden safety hazards in enterprises, and long time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

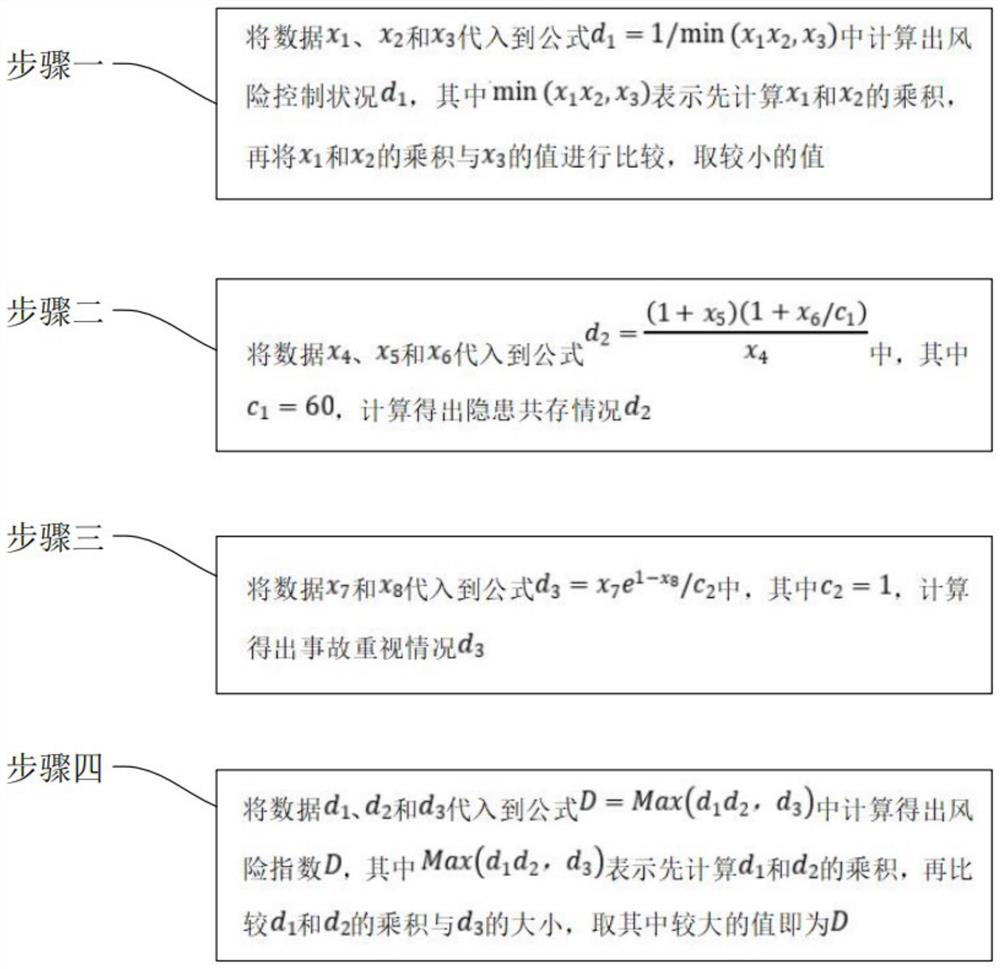

Method used

Image

Examples

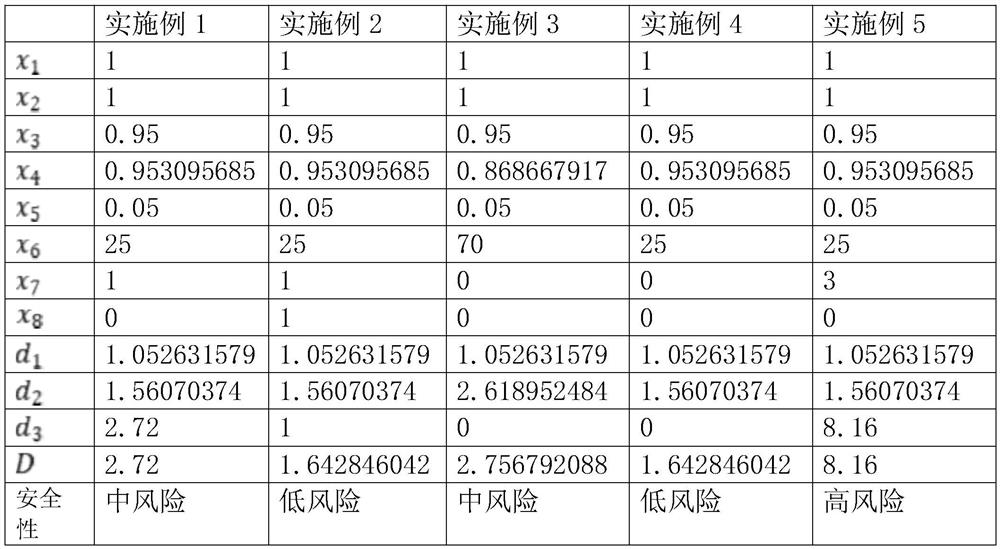

Embodiment 1

[0057] According to the survey, the relevant data of the enterprise are as follows: the ratio of the number of control measures associated with inspection items to the number of all control measures x 1 The value of is 1, and the ratio of the actual number of inspections to the number of planned inspections is x 2 The value of is 1, and the percentage of risky locations that have been safely inspected to all risky locations is x 3 The value of is 0.95, and the hidden dangers that have been rectified account for the percentage of all discovered hidden dangers x 4 The value of 0.953095685, the hidden dangers that have expired account for the percentage of all discovered hidden dangers x 5 The value of is 0.05, the number of current hidden dangers x 6 The number is 25, the number of minor injuries or breakdowns in the last 12 months x 7 The value of is 1, and no security risk analysis has been performed in the past 3 months, then x 8 The value is 0, calculated by the method o...

Embodiment 2

[0059] The ratio of the number of control measures associated with inspection items to the number of all control measures x 1 The value of is 1, and the ratio of the actual number of inspections to the number of planned inspections is x 2 The value of is 1, and the percentage of risky locations that have been safely inspected to all risky locations is x 3 The value of is 0.95, and the hidden dangers that have been rectified account for the percentage of all discovered hidden dangers x 4 The value of 0.953095685, the hidden dangers that have expired account for the percentage of all discovered hidden dangers x 5 The value of is 0.05, the number of current hidden dangers x 6 The number is 25, the number of minor injuries or breakdowns in the last 12 months x 7 The value is 1, and there has been security risk analysis in the past 3 months, then x 8 The value is 1, calculated by the method of the present invention, x 1 、x 2 and x 3 Substitute into formula d 1 =1 / min(x 1 ...

Embodiment 3

[0061] The ratio of the number of control measures associated with inspection items to the number of all control measures x 1 The value of is 1, and the ratio of the actual number of inspections to the number of planned inspections is x 2 The value of is 1, and the percentage of risky locations that have been safely inspected to all risky locations is x 3 The value of is 0.95, and the hidden dangers that have been rectified account for the percentage of all discovered hidden dangers x 4 The value of 0.868667917, the hidden dangers that have expired account for the percentage of all discovered hidden dangers x 5 The value of is 0.05, the number of current hidden dangers x 6 The number is 70, the number of minor injuries or breakdowns in the last 12 months x 7 The value of is 0, and no security risk analysis has been performed in the past 3 months, then x 8 The value is 0, calculated by the method of the present invention, x 1 、x 2 and x 3 Substitute into formula d 1 =1 / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com