Transformer body pressing device for power transformer

A technology for power transformers and compression devices, which is applied in the field of transformers, can solve problems such as inability to protect the transformer, limit the body of the device, and damage the transformer, and achieve the effect of improving installation efficiency and simple and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

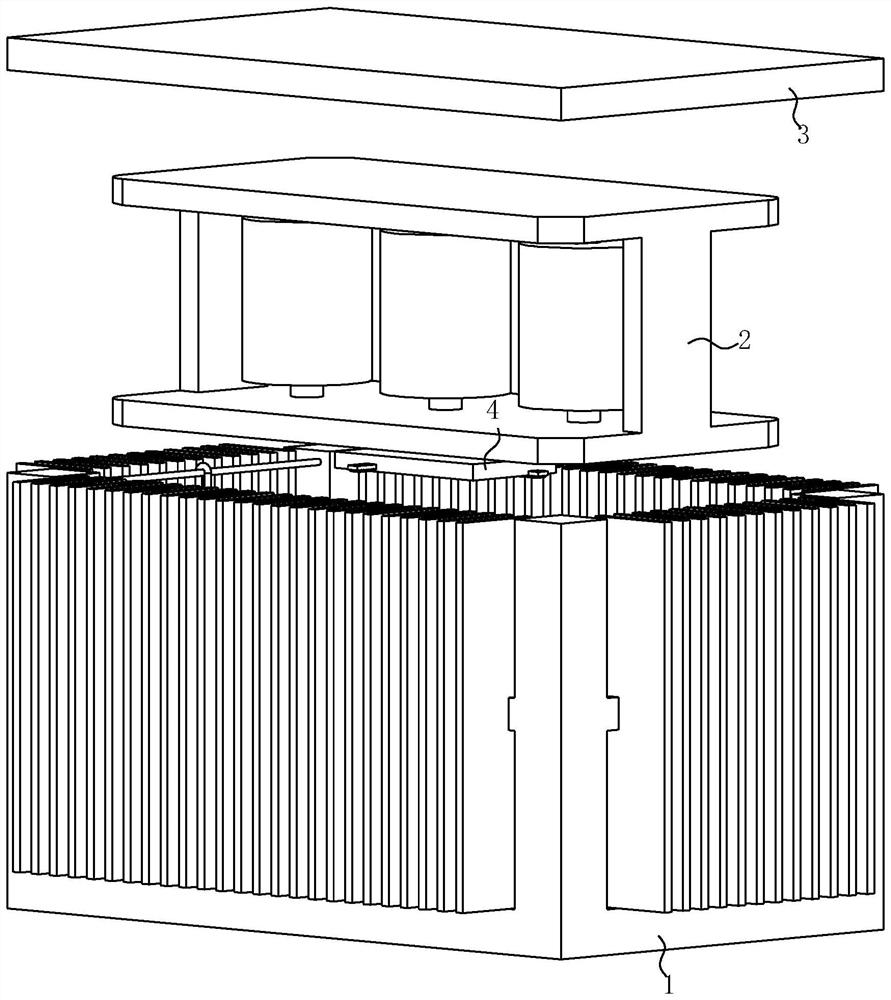

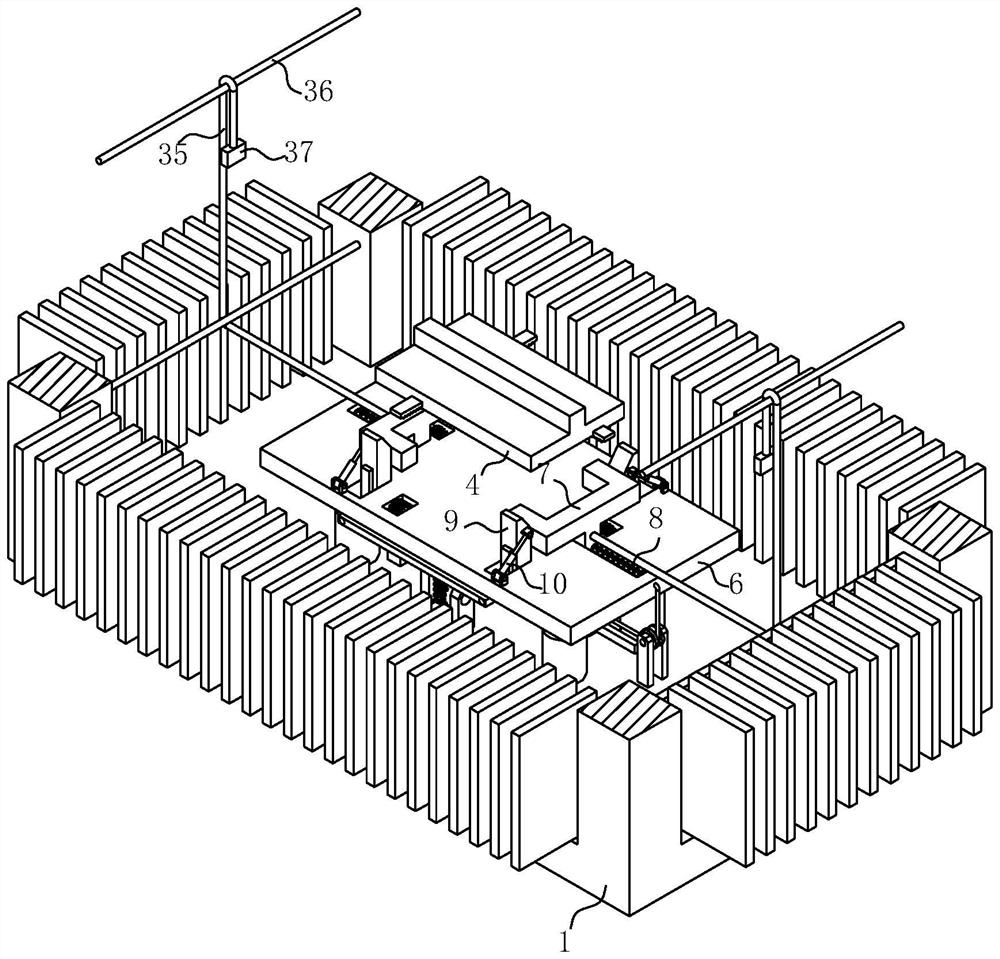

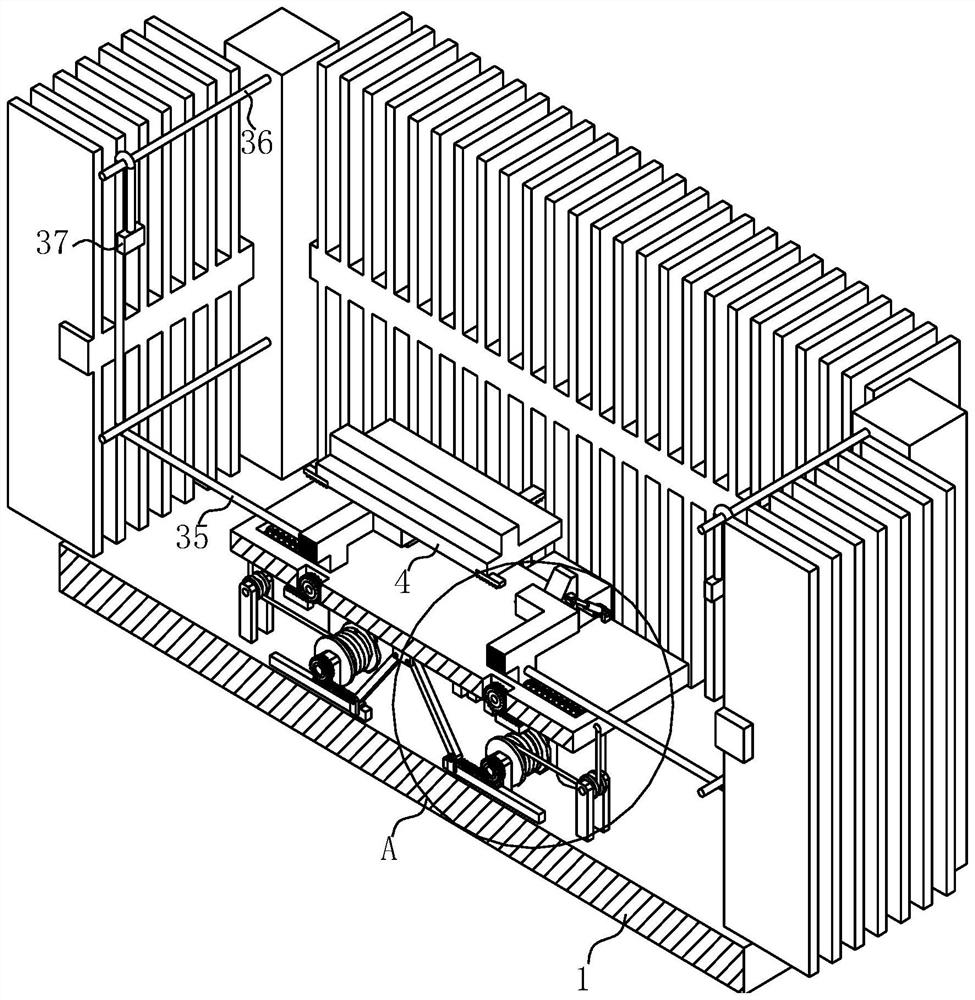

[0029] see Figure 1-9 , the present invention provides a technical solution: a body pressing device for a power transformer, comprising a transformer oil tank 1, a transformer body 2 and a cover plate 3, the bottom of the transformer body 2 is fixedly connected with a T-shaped slider 4 , the bottom of the transformer oil tank 1 is fixedly connected with a first gas spring 5, the top of the first gas spring 5 is fixedly connected with a first fixing plate 6, and the left and right sides of the top of the first fixing plate 6 are slidingly connected There is a C-shaped limiting plate 7, and the two C-shaped limiting plates 7 are respectively used to limit the left and right ends of the T-shaped slider 4; the C-shaped limiting plate 7 is fixedly connected with a The first spring 8, the front and rear sides of the top of the first fixed plate 6 are slidably connected to the limit rods 9, and the two limit rods 9 are used to limit the front and rear ends of the T-shaped slider 4 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com