Sulfur-containing porous Yolk-shell structure particle as well as preparation method and application thereof

A particle and elemental sulfur technology, applied to structural parts, electrical components, battery electrodes, etc., can solve the problems of shell structure damage and reduce the restrictive effect of shell structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The invention provides a method for preparing sulfur-containing porous Yolk-shell particles, comprising the following steps:

[0038] (1) mixing elemental sulfur with an oil phase solvent to obtain an oil phase;

[0039] (2) mixing the emulsifier with water to obtain an aqueous phase;

[0040] (3) mixing the oil phase obtained in the step (1) with the water phase obtained in the step (2), and emulsifying to obtain a mixed solution;

[0041] (4) Evaporating the oil phase solvent in the mixed solution obtained in the step (3) to obtain sulfur-containing porous Yolk-shell particles;

[0042] The steps (1) and (2) are in no sequence.

[0043] The present invention mixes elemental sulfur with an oil phase solvent to obtain an oil phase.

[0044] In the present invention, the source of the elemental sulfur is not particularly limited, and commercially available products well known to those skilled in the art can be used. In the present invention, there is no special limit...

Embodiment 1

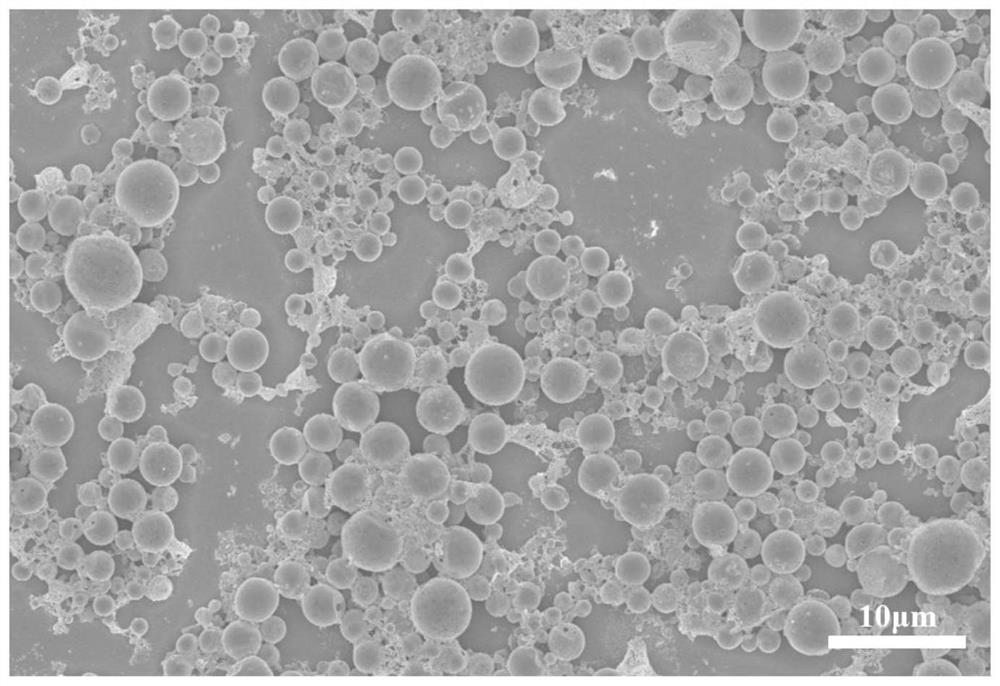

[0079] The preparation method of sulfur-containing porous Yolk-shell structure particles is as follows:

[0080] (1) 0.5g of elemental sulfur is dropped into 10mL of carbon disulfide, and mixed to obtain an oil phase;

[0081] (2) Dissolve 2.5g of PVA in 100mL of pure water at 95°C to obtain the water phase;

[0082] (3) Mix the oil phase obtained in the step (1) with the water phase obtained in the step (2), emulsify in an emulsifier at 5000r / min for 5min, and then let stand for 2h to obtain an emulsion;

[0083] (4) Add 5g of glutaraldehyde aqueous solution (concentration is 50wt%) in the emulsion that described step (3) obtains, slowly stir at 25 ℃ and carry out cross-linking reaction 12h, carry out centrifugal separation, washing successively again, obtain glue Beam particles; wherein, the centrifugal separation speed is 8000rpm, and the time is 10min; the washing operation is pure water washing twice;

[0084] (5) stirring and dispersing the micelle particles obtained i...

Embodiment 2

[0096] On the basis of embodiment 1, the number of porous aluminum foil holes in step (6) is changed to 10, and the evaporation rate is 0.25mg / min; other conditions are constant, and obtain sulfur-containing porous Yolk-shell structure particles, which are denoted as S@ PVA2 particles.

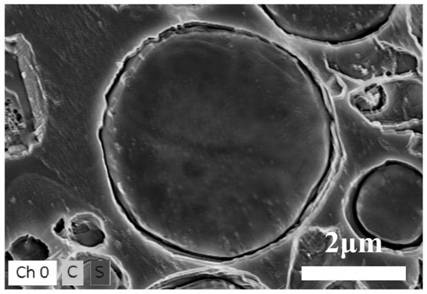

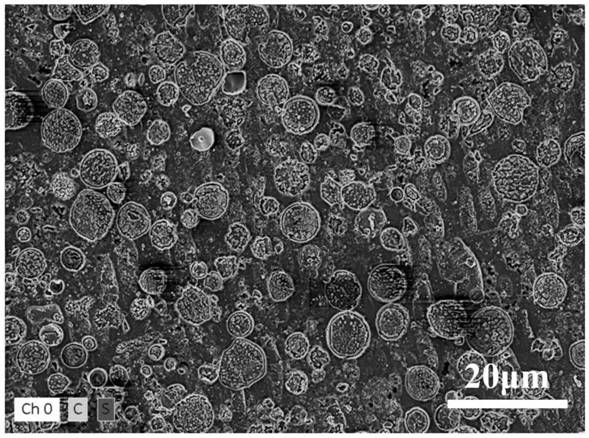

[0097] Figure 8 Scanning electron micrograph of the sulfur-containing porous Yolk-shell particles prepared in Example 2. from Figure 8 It can be seen that the number of surface pores of the Yolk-shell particles is reduced, and the surface porosity is 0.35%, which is about 81% lower than that of the particles prepared in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com