Overcurrent protection circuit and driving circuit of display panel

An overcurrent protection circuit and current technology, which is applied in the direction of emergency protection circuit devices, overcurrent protection, circuit devices, etc., can solve problems such as drive circuit damage, display panel burnout, device damage, etc., to avoid device Loss caused by damage, stable protection effect, good over-current protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

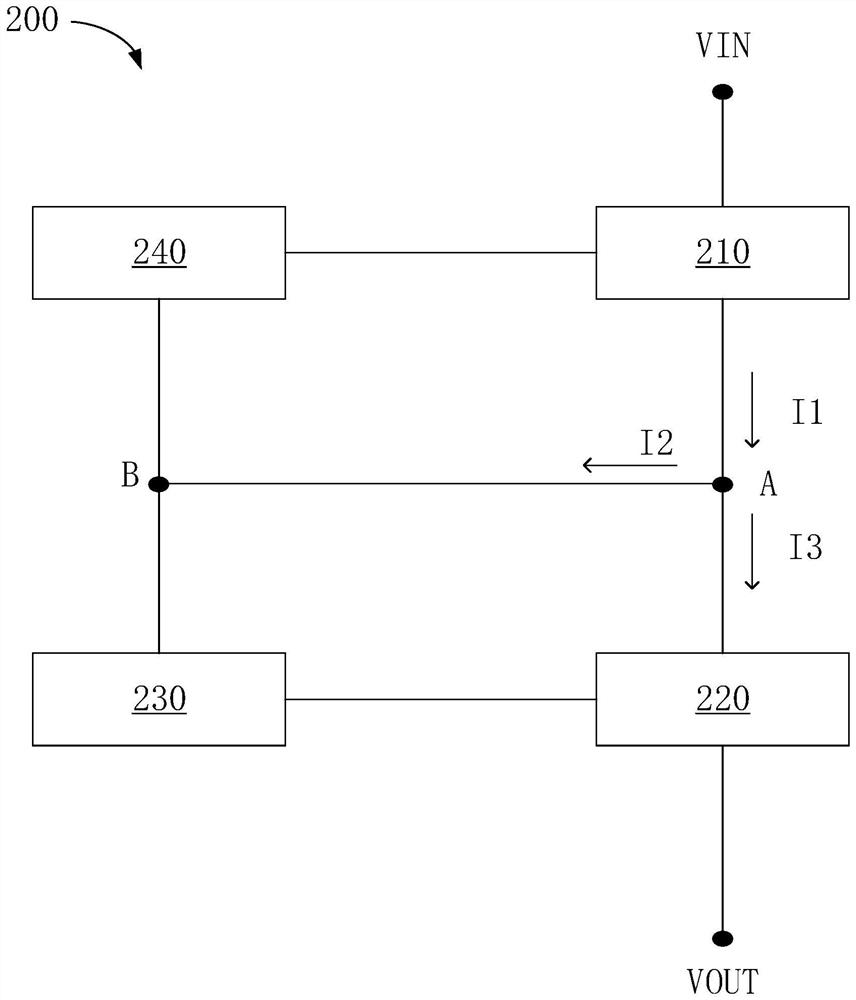

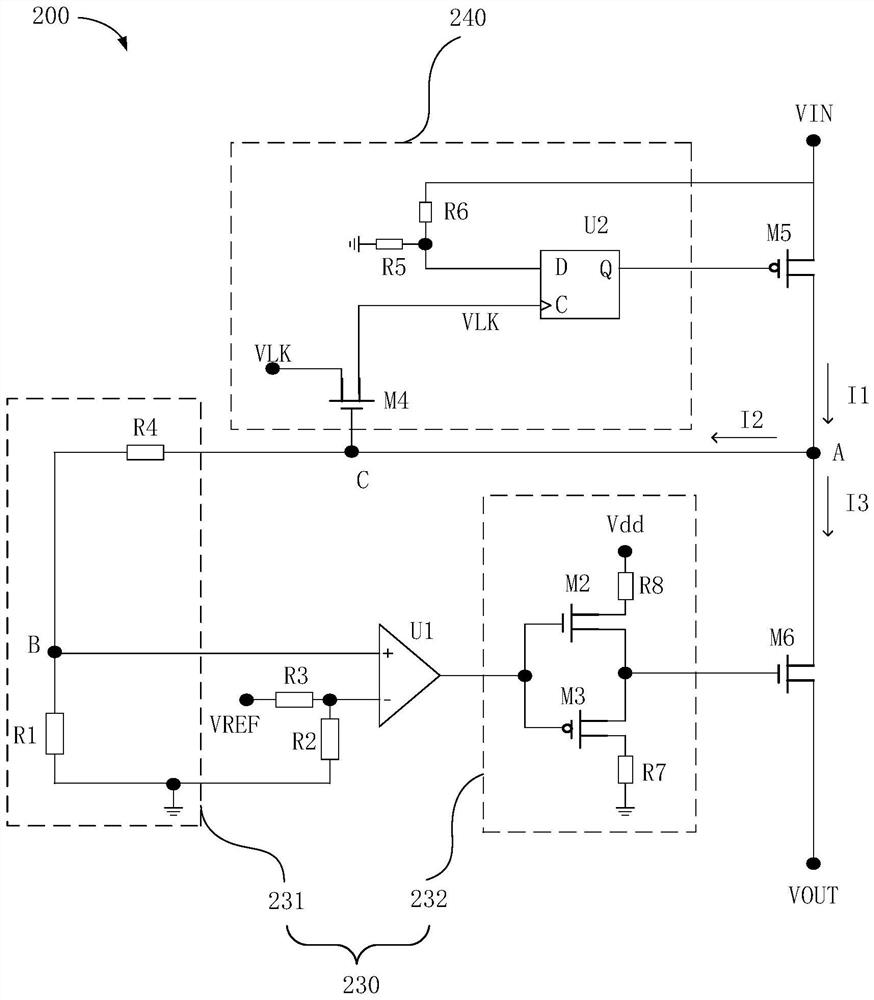

[0050] Figure 2a It is a schematic circuit diagram of an overcurrent protection circuit in the embodiment of the present application, refer to Figure 2a It can be seen that, as the first embodiment of the present application, the first detection module 230 includes a detection unit 231 and a voltage comparison unit U1, the input terminal of the detection unit 231 is connected to one end of the detection branch, and the detection unit 231 flows from the detection branch. The current at the input end of the detection unit 231 is the current I to be detected; the output end of the detection unit 231 is connected to the first input end of the voltage comparison unit U1, and the received current I to be detected is converted into a first detection voltage and sent to the voltage comparison unit Unit U1; the second input terminal of the voltage comparison unit U1 is connected to the first reference voltage VREF, and the output terminal of the voltage comparison unit U1 is connecte...

Embodiment 2

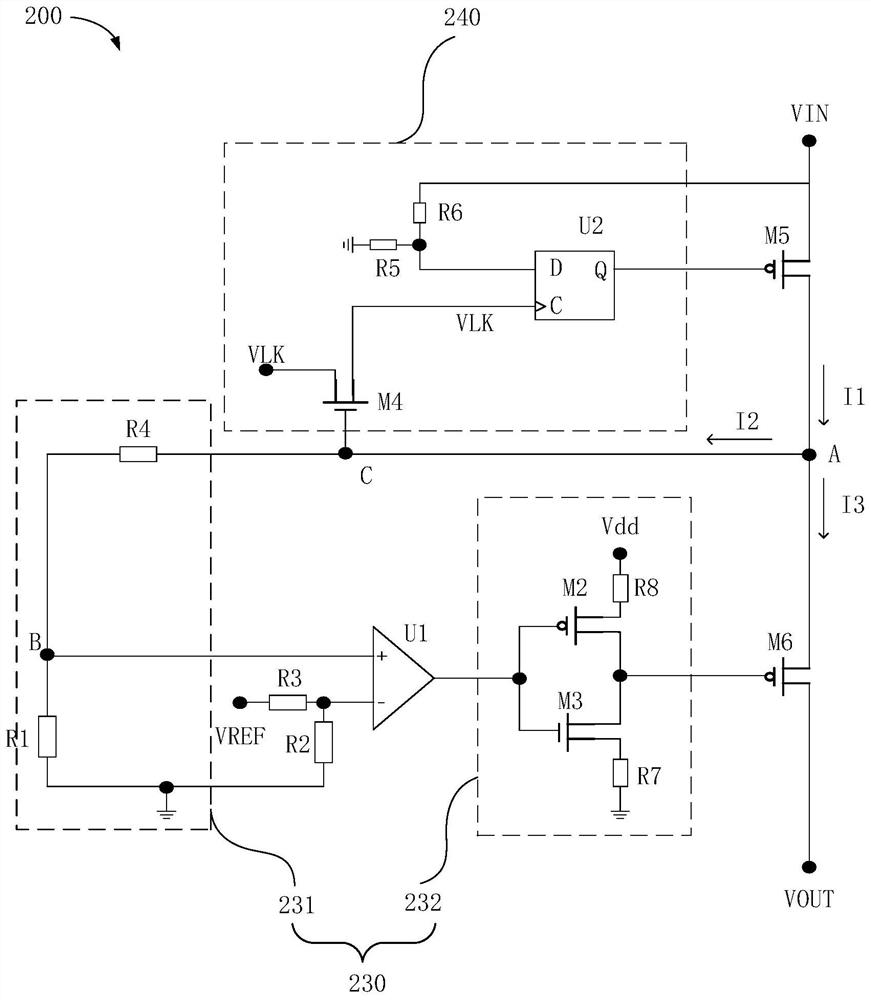

[0069] Figure 3a It is a schematic circuit diagram of the overcurrent protection circuit of Embodiment 2 of the present application. Referring to FIG. 3, it can be seen that as Embodiment 2 of the present application, the difference from Embodiment 1 is that the detection unit 231 also includes a first resistor R1 and a first switch M1 , one end of the first resistor R1 is connected to one end of the detection branch, and the current flowing into the first resistor R1 from the detection branch is the current I to be detected; the other end of the first resistor R1 is grounded; the control terminal of the first switch M1 is connected to Between the detection branch and the first resistor R1; the input end of the first switch M1 is connected to the second reference voltage Vb; the output end of the first switch M1 is grounded; the first input end of the voltage comparison unit U1 is connected to the first switch The input terminal of M1, the voltage at the input terminal of the...

Embodiment 3

[0078] Figure 4a It is the circuit schematic diagram of the overcurrent protection circuit of the third embodiment of the present application, refer to Figure 4a It can be seen that, as the third embodiment of the present application, the difference from the first embodiment is that the detection unit 231 includes a transistor T1, the base of the transistor T1 is connected to one end of the detection branch, and the power flowing into the transistor T1 from the detection branch is The current of the base is the current I to be detected; the emitter of the transistor T1 receives the second reference voltage Vb; the collector of the transistor T1 is grounded; the first input terminal of the voltage comparison unit U1 is connected to the emitter of the transistor T1, The voltage of the emitter of the transistor T1 is the first detection voltage.

[0079] In this embodiment, the current change is converted into the first detection voltage through the transistor T1, and the tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com