Circuit board routing method

A technology of circuit boards and gongs, which is applied in printed circuits, printed circuit manufacturing, and removal of conductive materials by mechanical methods. It can solve problems such as large depth tolerance of finished products, failure to install products smoothly, and broken knives.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

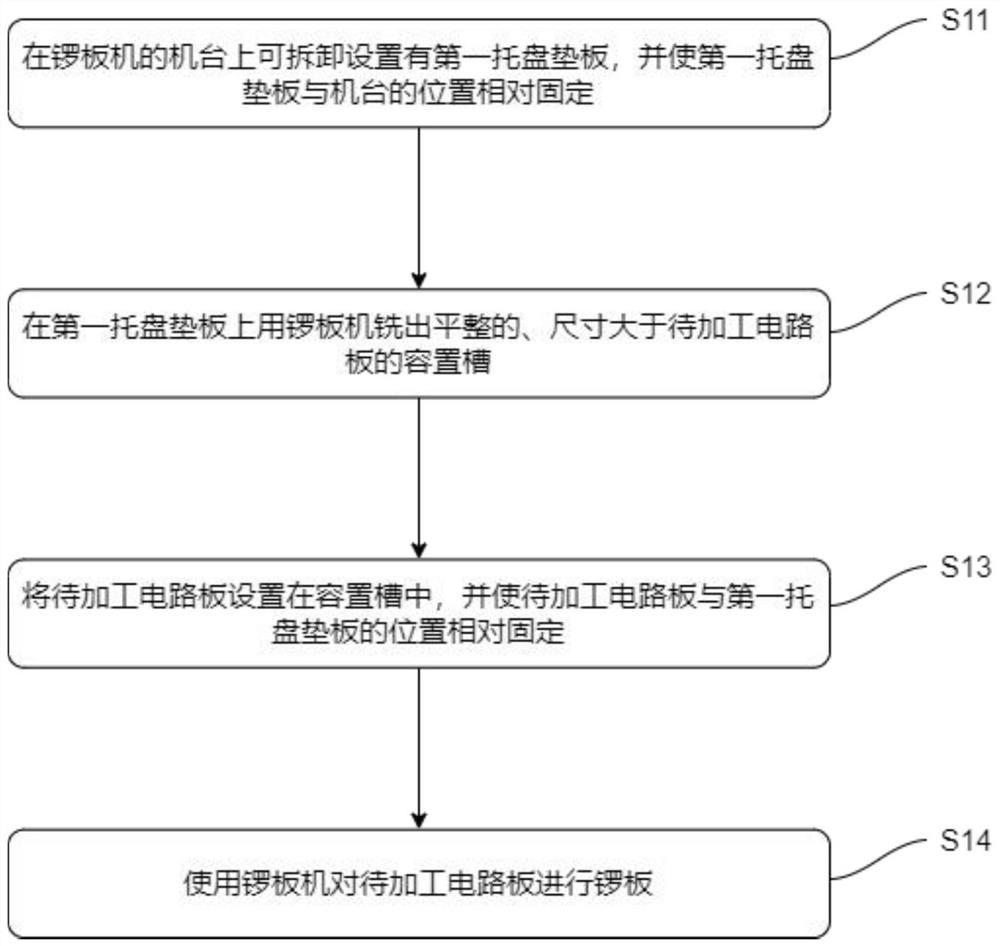

[0029] figure 1 A flow chart of a circuit board gong board method according to an embodiment of the present invention is schematically shown.

[0030] This embodiment provides a circuit board gong board method, referring to figure 1 , including the following steps:

[0031] Step S11: a first tray backing plate is detachably arranged on the machine table of the gong plate machine, and the positions of the first tray backing plate and the machine table are relatively fixed;

[0032] Specifically, in this step S11, the bottom plate of the gong board machine is the position used to place the circuit board to be processed in the general gong board machine, the first tray backing plate is a component used to process the accommodating groove, and the second The specific thickness and shape of a pallet backing plate are not limited, as long as the accommodating groove of the required size can be processed by the milling cutter of the gong plate machine, in this embodiment, the first...

Embodiment 2

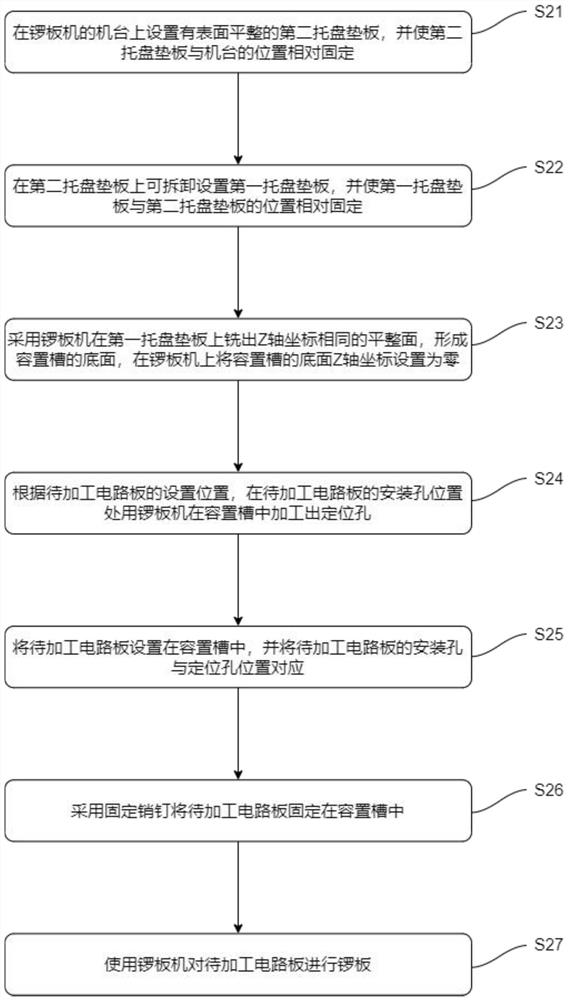

[0041] figure 2 A flow chart of a circuit board gong board method according to another embodiment of the present invention is schematically shown.

[0042] The application provides a circuit board gong board method, referring to figure 2 , including the following steps:

[0043] Step S21: a second tray backing plate with a flat surface is arranged on the machine table of the gong plate machine, and the position of the second tray backing plate and the machine table is relatively fixed;

[0044] In step S21, when the position of the second tray backing plate is relatively fixed to the machine platform, the specific method may be to use screws to fix the second tray backing plate on the machine table, such as on the four sides of the second tray backing plate. The corner position is connected with the machine table by screws, so that the position of the second pallet backing plate and the machine table is relatively fixed, so as to avoid the relative displacement between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com