Folding and pressing equipment for flexible sheet material and processing technology

A technology of sheet material and pressing equipment, applied in the field of mechanical processing, can solve the problems of cumbersome folding and pressing process, and achieve the effect of reducing the folding and pressing process, ensuring the uniformity and improving the positioning accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

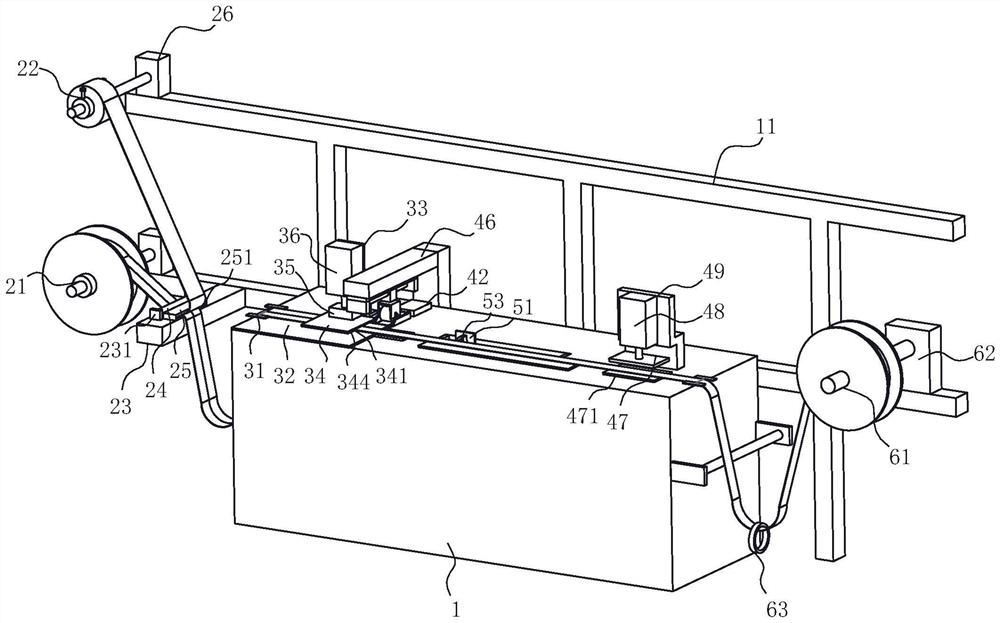

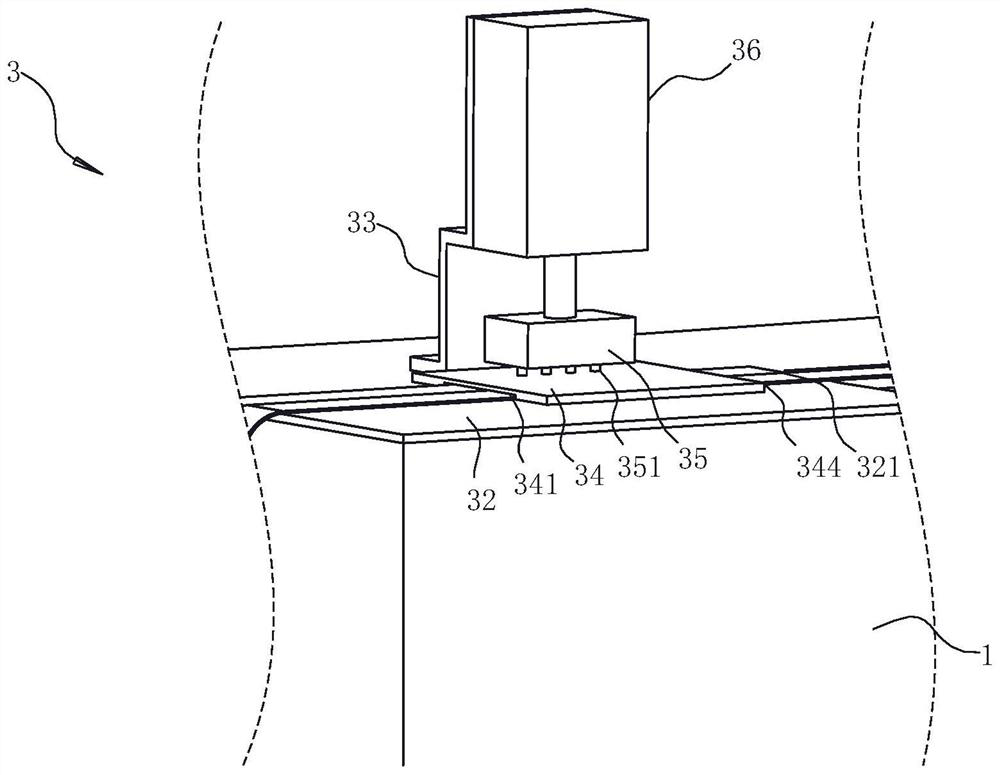

[0050] refer to figure 1 , a device for folding and laminating flexible sheet materials includes an installation table 1 , a film separating mechanism 2 , a leveling mechanism 3 , a folding and laminating mechanism 4 , a transmission mechanism 5 and a winding mechanism 6 .

[0051] A base frame 11 is provided on the side wall of the installation platform 1 . In this embodiment, the installation platform 1 is arranged in a rectangular shape, and the base frame 11 is located on the side wall of the installation platform 1 along the length direction and is fixedly connected with the side wall. The leveling mechanism 3 , the folding and pressing mechanism 4 , and the transmission mechanism 5 are all installed on the installation platform 1 in sequence, and the film separating mechanism 2 and the winding mechanism 6 are respectively installed at both ends of the base frame 11 .

[0052] The film separation mechanism 2 is used to separate the dust-proof film and the material. The f...

Embodiment 2

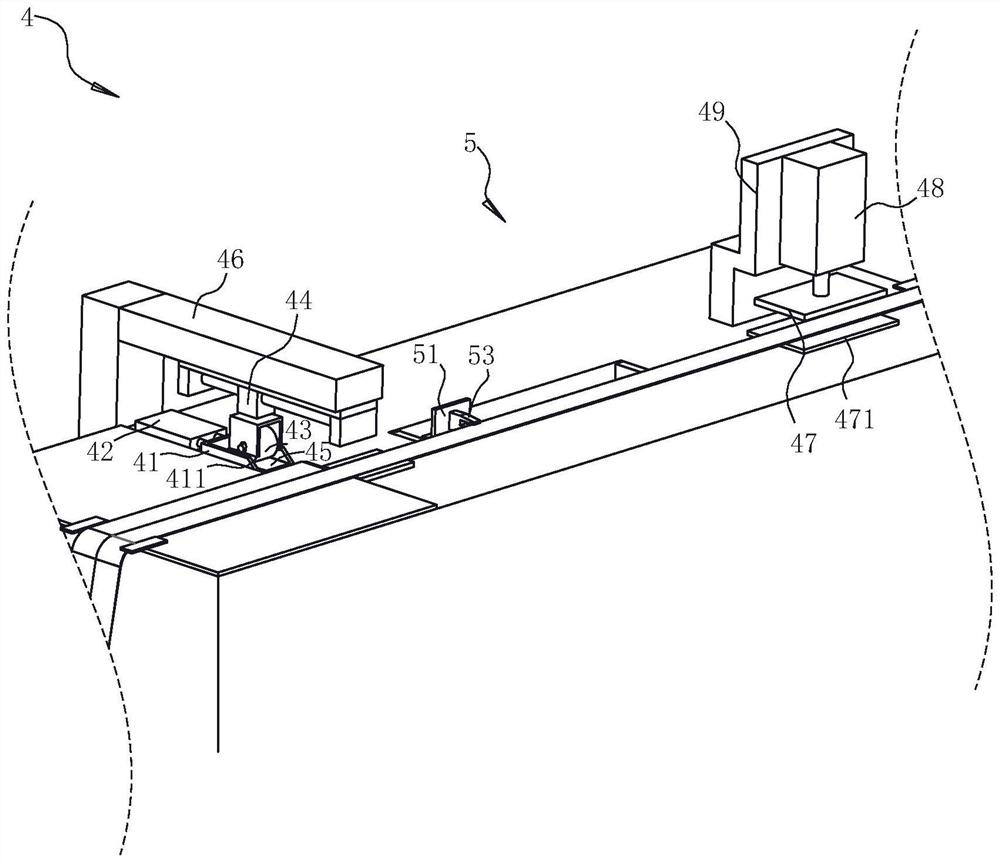

[0070] refer to Figure 4 and Figure 5 , The difference between this embodiment and Embodiment 1 is that, in this embodiment, two groups of raw materials are processed at the same time. The raw material conveying roller 21 and the film take-up roller 22 are respectively provided with spacers, two groups of raw materials are installed on both sides of the spacer of the raw material conveying roller 21 respectively, and the dust-proof films are installed on both sides of the spacer of the film take-up roller 22 respectively. side; the separation block 25 is set in two groups, which are respectively used to separate two groups of raw materials; the leveling block 34 is set in two groups, and the two groups of materials are respectively leveled and limited. There are positioning columns 351 for piercing the material holes. There are eight positioning columns 351. Every four positioning columns 351 form a group and are arranged at intervals along the processing direction of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com