Pantograph structure for train

A technology for pantographs and trains, which is applied in the field of rail transit, and can solve the problems of tail instability, affecting the normal operation of trains, and aerodynamic noise, so as to reduce aerodynamic noise and aerodynamic resistance, weaken the phenomenon of Karman vortex street, and improve the stability of train operation sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

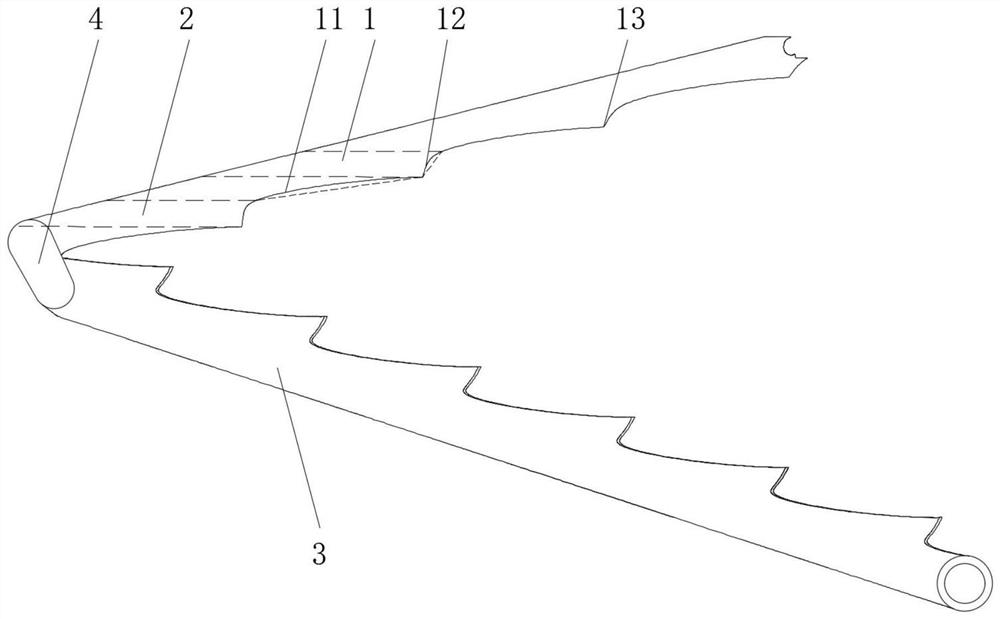

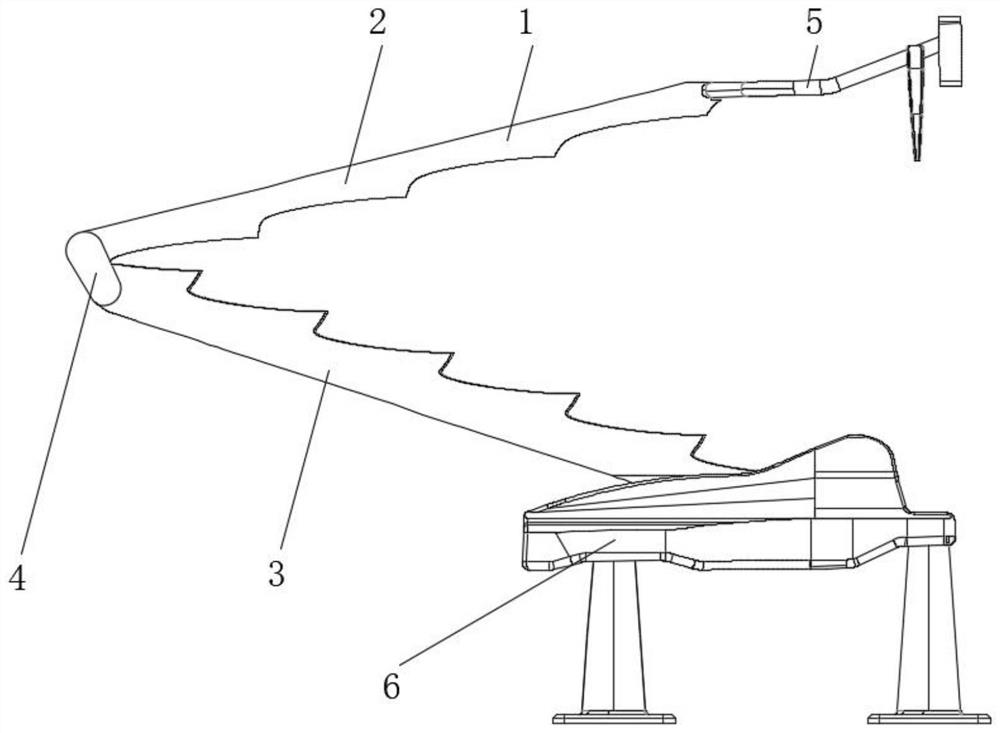

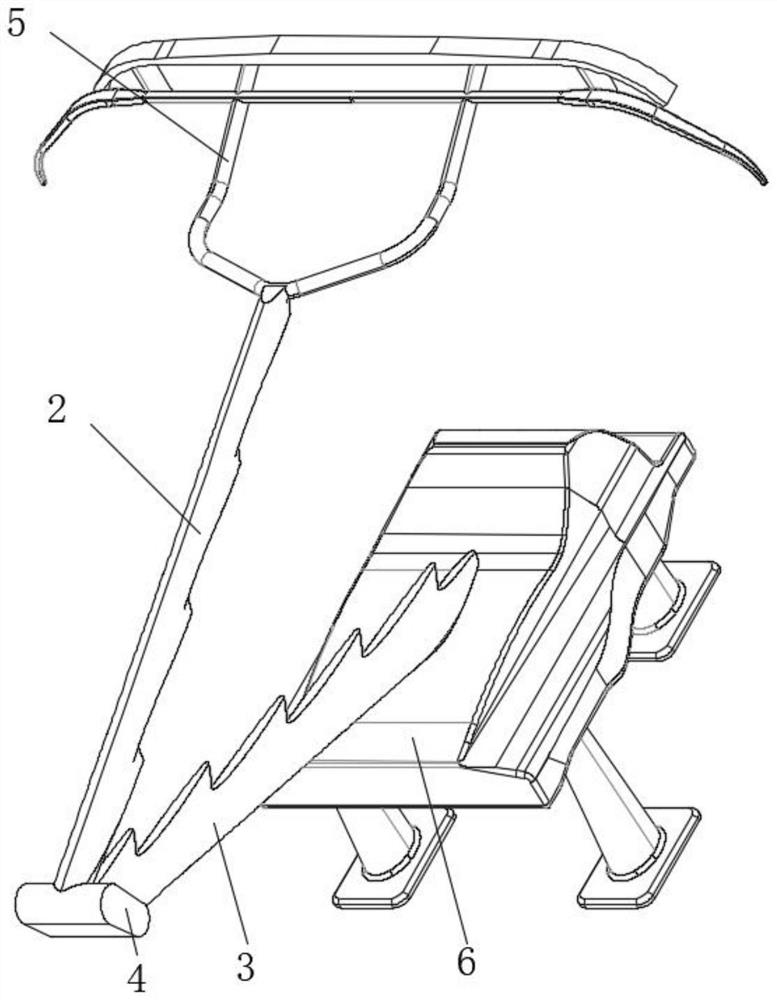

[0025] like figure 1 As shown, the train pantograph structure of this embodiment includes a boom 1, the horizontal section of the boom 1 is an airfoil structure whose transverse width first increases along the wind direction and then gradually shrinks, and the curved surface of the leeward side of the boom 1 is along the direction of the boom 1. Axial ups and downs. Compared with the surface of the existing cylindrical structure, the airfoil section in this embodiment can effectively guide the air flow in the leeward side of the pantograph arm, adjust the tail airflow through the gradually narrowing airfoil structure on the leeward side, and delay the high-speed airflow in the power receiving area. The strong flow separation on the front and leeward sides of the bow arm weakens the Karman vortex street phenomenon at the rear of the arm and weakens the lateral vibration of the pantograph arm. like Image 6 as shown, Image 6 The above is a conventional cylindrical arm, Ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com