Sealed threaded connection assembling method for combination of oil pipe and casing pipe

A technology of threaded connection and assembly method, which is applied in the direction of casing, drill pipe, earthwork drilling and mining, etc., and can solve the problems of counter-torque loosening at the factory end, and the shoulder face is not in place.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

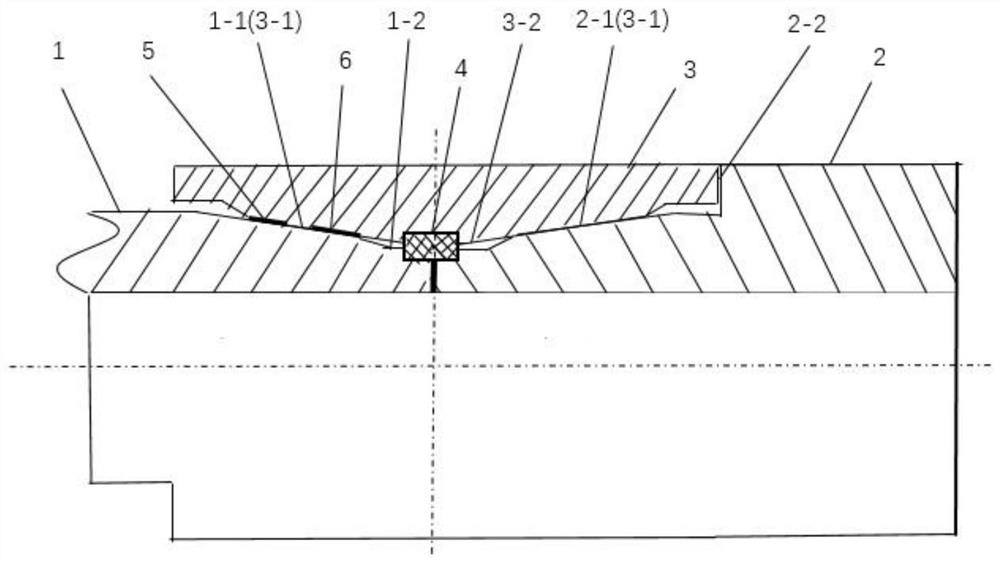

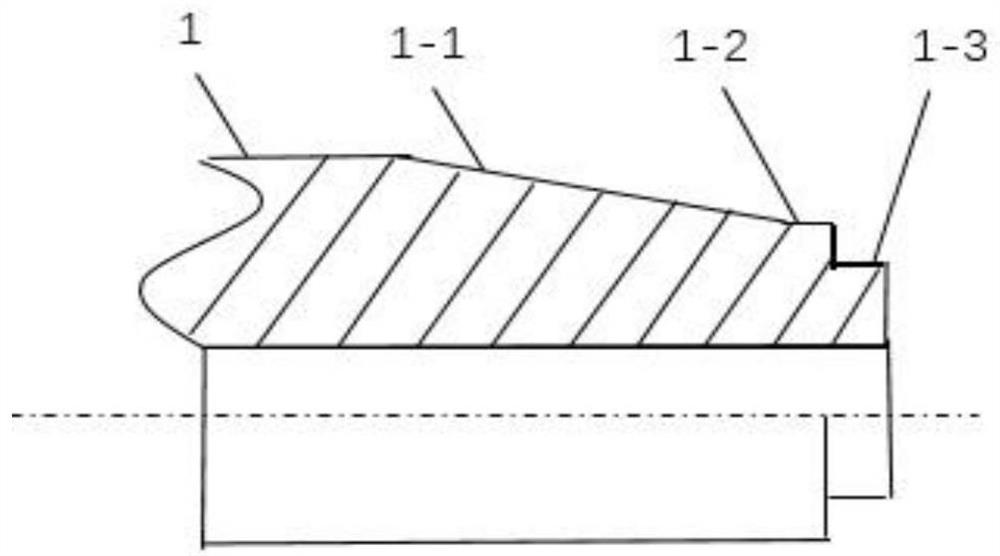

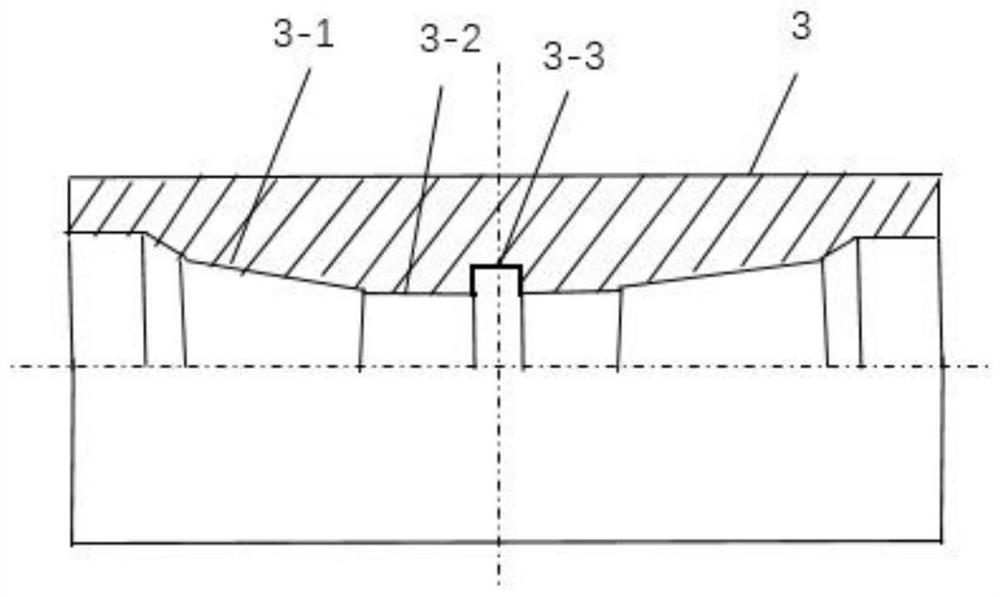

[0048] Such as figure 1 An economical oil and casing thread structure of the present invention includes a pipe body 1, an assembly pup joint 2, a connecting collar 3, a V-shaped rubber seal 4, an anti-loosening and locking thread grease 5 and an anti-seize oil casing Thread grease 6; the end of pipe body 1 is processed with external thread 1-1, the front end of external thread is processed with nose shoulder 1-2, and the nose shoulder is provided with sealing step surface 1-3; the two ends of connecting collar 3 are respectively processed with The internal thread 3-1 matched with the external thread of the pipe is processed with a hollow cylindrical section 3-2 in the middle of the connecting coupling, and the inner surface of the cylindrical section is provided with a sealing groove 3-3; the assembly nipple 2 is an external thread joint with a positioning shoulder , When the pipe body 1 is assembled with the connecting collar 3, it is necessary to use the anti-loosening and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com