Sealing body and insulating pad, ceramic core assembly manipulator, system and method based on six-axis robot

A six-axis robot and insulating pad technology, applied in sorting and other directions, can solve the problems of false positive and negative sides of insulating pads/porcelain cores, misjudgment of qualification, high labor intensity, unstable manual assembly, etc., to achieve low cost and work. High efficiency and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

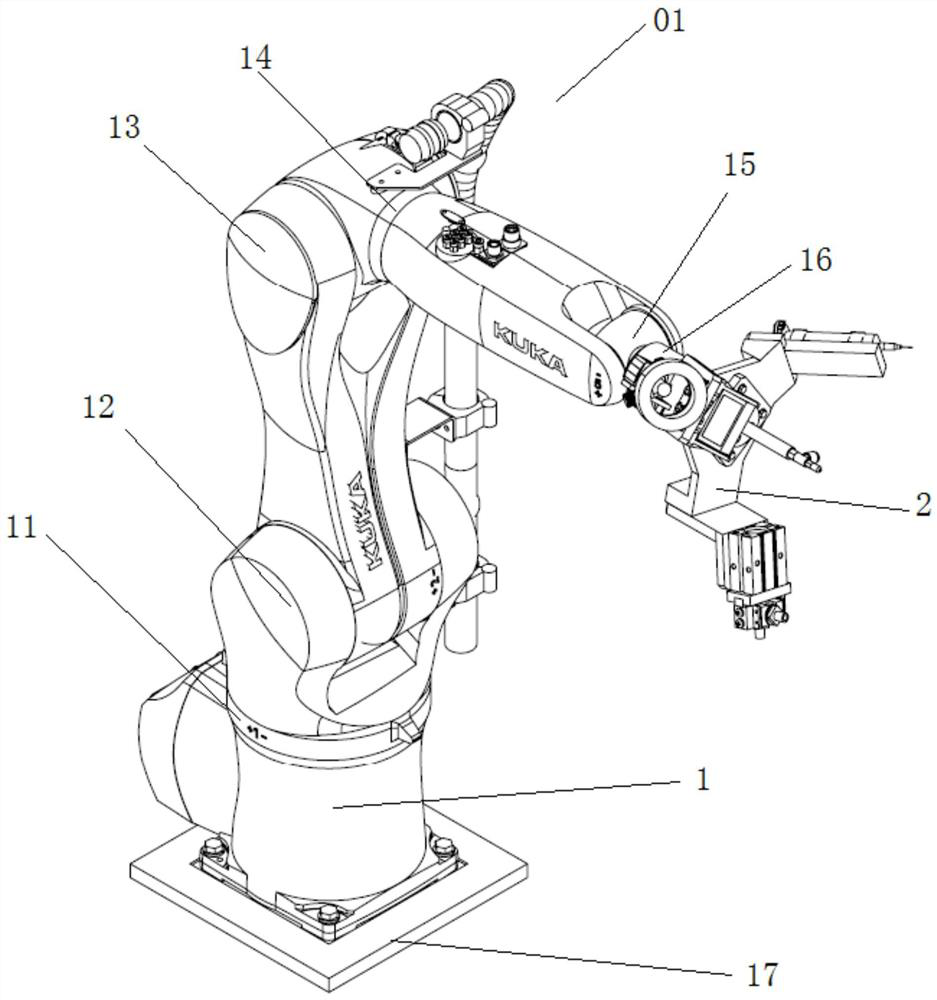

[0088] Such as figure 1 As shown, a sealing body, insulating pad, and ceramic core assembly manipulator based on a six-axis robot, including a base, a six-axis robot 1 set on the base, and a glue injection jig assembly set on the working axis of the six-axis robot 1 2. The six axes of the six-axis robot 1 are the first axis 11 , the second axis 12 , the third axis 13 , the fourth axis 14 , the fifth axis 15 and the working axis 16 .

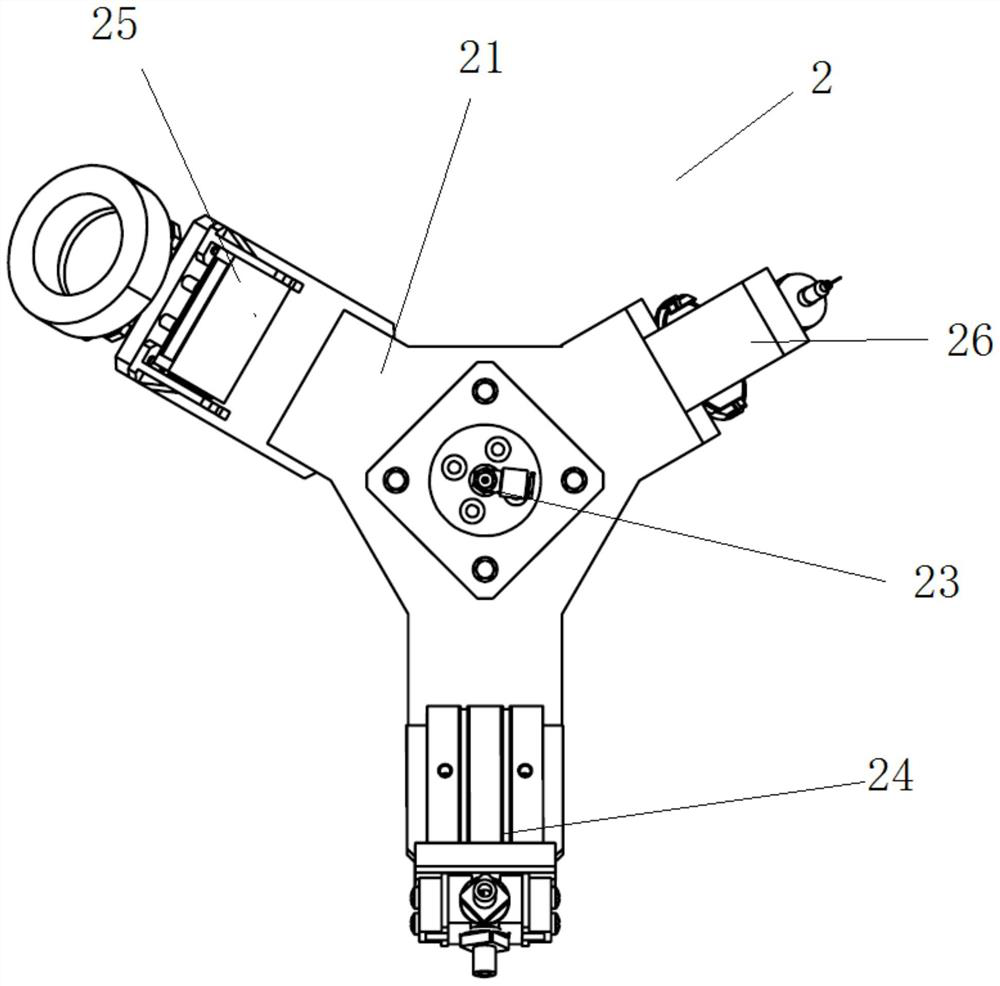

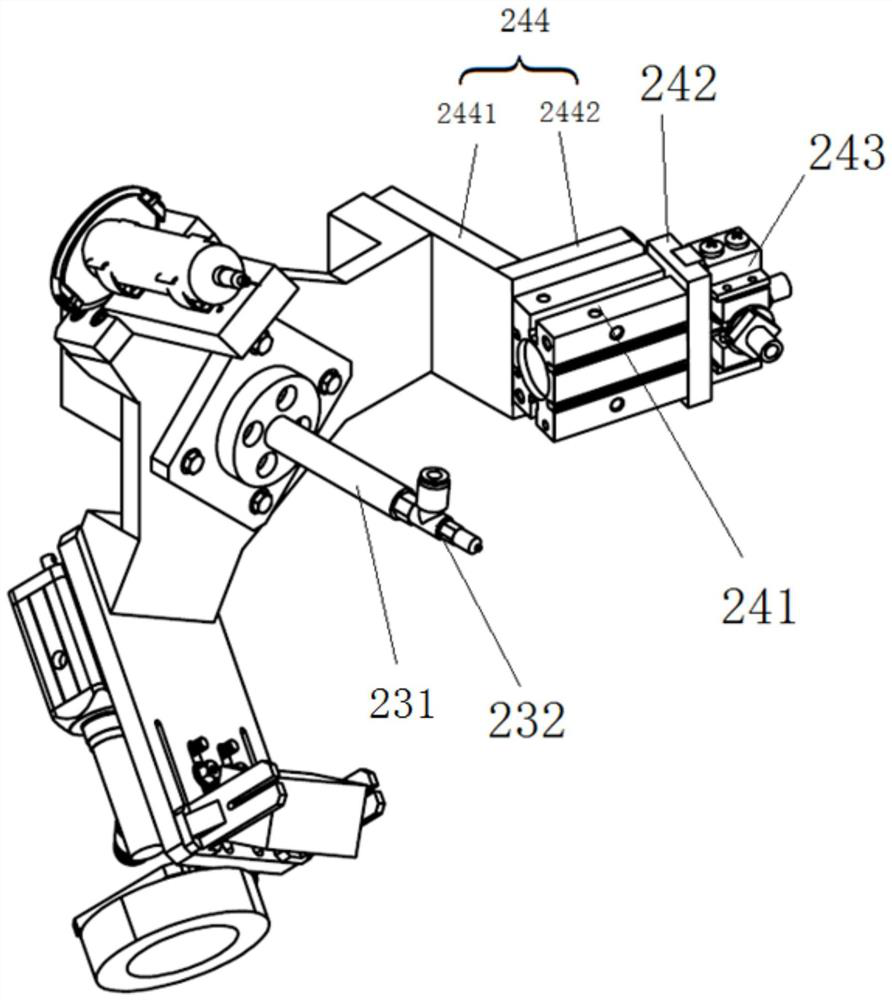

[0089] Such as Figure 2 to Figure 4As shown, the glue injection fixture assembly 2 includes a glue injection fixture connecting plate 21, a connecting flange 22 connected to the glue injection fixture connecting plate 21, a suction fixture 23, a sealing body grasping fixture 24, a visual system 25. Gluing system 26; the connecting flange 22 is located in the middle of the upper surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com