Composite cable for fire prevention

A composite cable and cable technology, which is applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of shortened cable service life, low cable strength, and inability to protect the sheath, so as to prolong the service life, improve the protection effect, and improve The effect of the anti-stretch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The implementation of the present application will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how the present application uses technical means to solve technical problems and achieve technical effects.

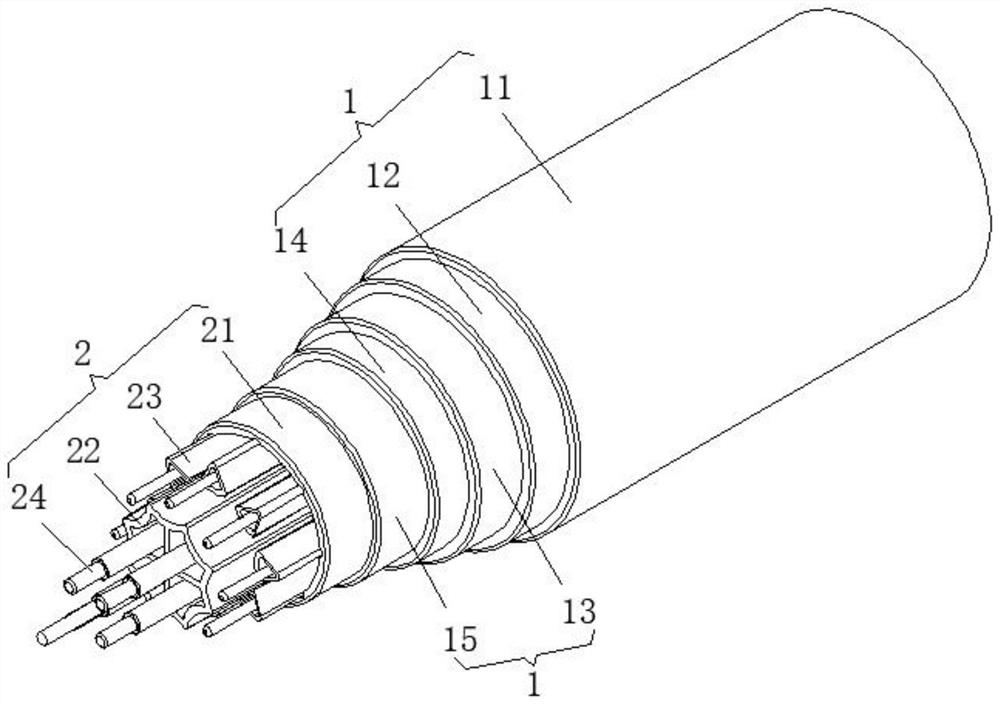

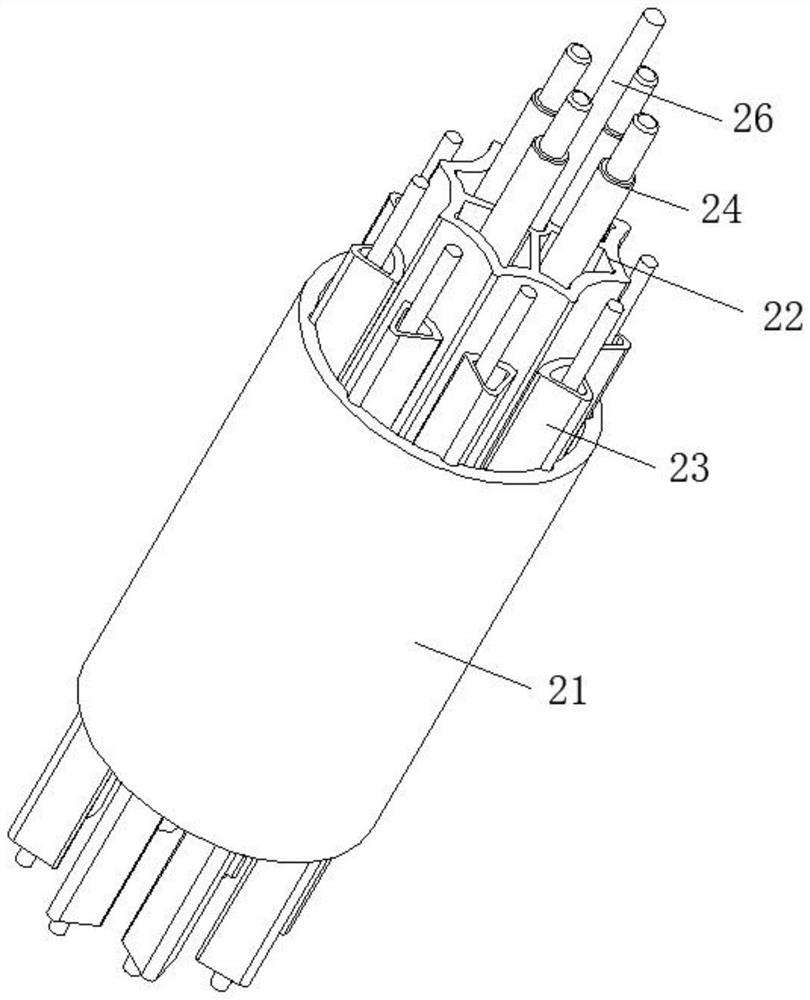

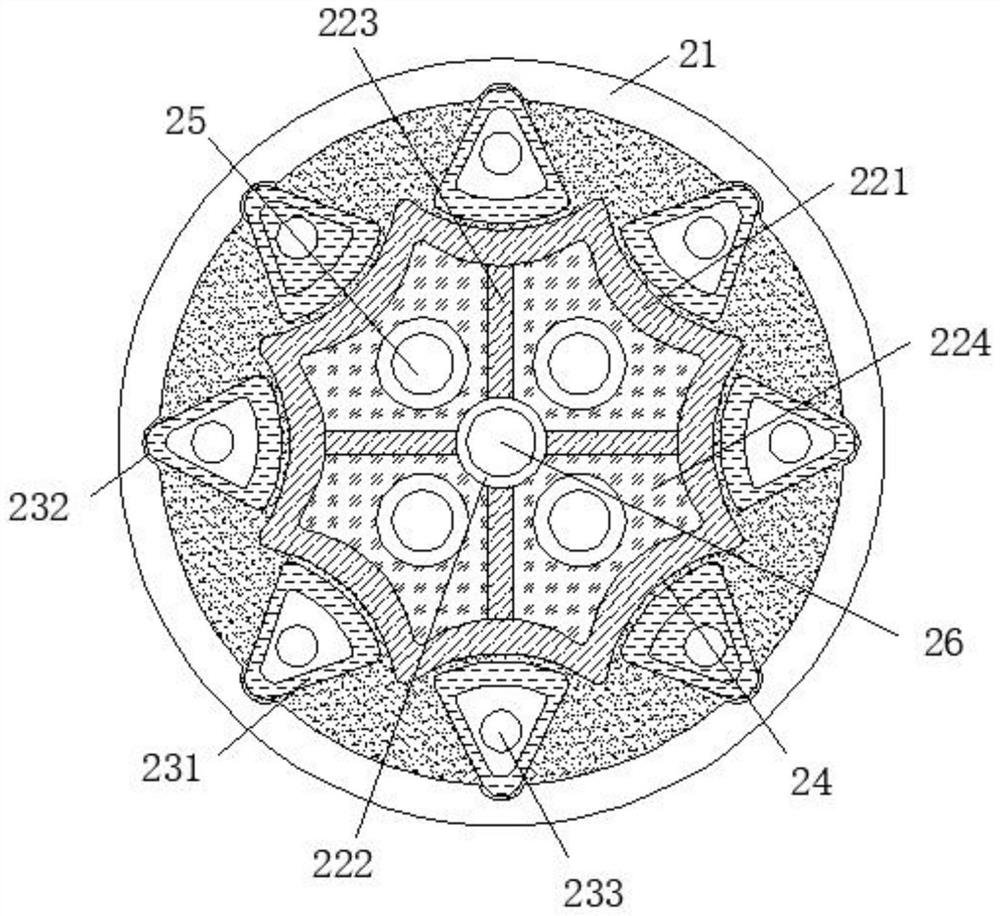

[0026] Figure 1-3 It is an embodiment of the present invention: a composite cable for fire prevention, including an outer protective part 1 providing protection for the cable, an inner protective part 2 is sheathed in the outer protective part 1, and the inner protective part 2 includes an inner sheath 21. The inner sheath 21 is provided with a reinforcement part 22, and a plurality of support parts 23 are provided between the reinforcement part 22 and the inner sheath 21. The outer wall of the reinforcement part 22 is provided with a plurality of depressions for use with the support part 23 24. A plurality of cable cores 25 are set inside the reinforcement...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com