Coating production line of mold retaining agent for aluminum template

A coating production line and aluminum formwork technology, which is applied to the surface coating liquid device, coating, cleaning method and utensils, etc., can solve the problems of affecting the quality of painting, inconsistent thickness of painting, inconsistent holding force, etc. Achieve the effects of improving brushing efficiency, improving cleanliness, and reducing the possibility of missing coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

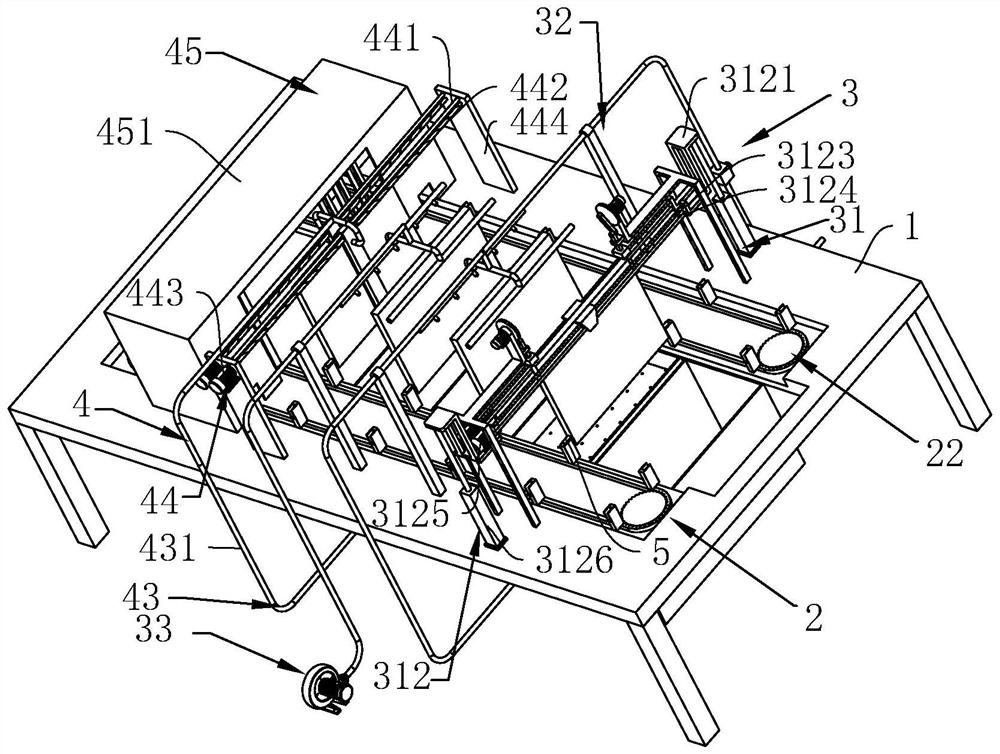

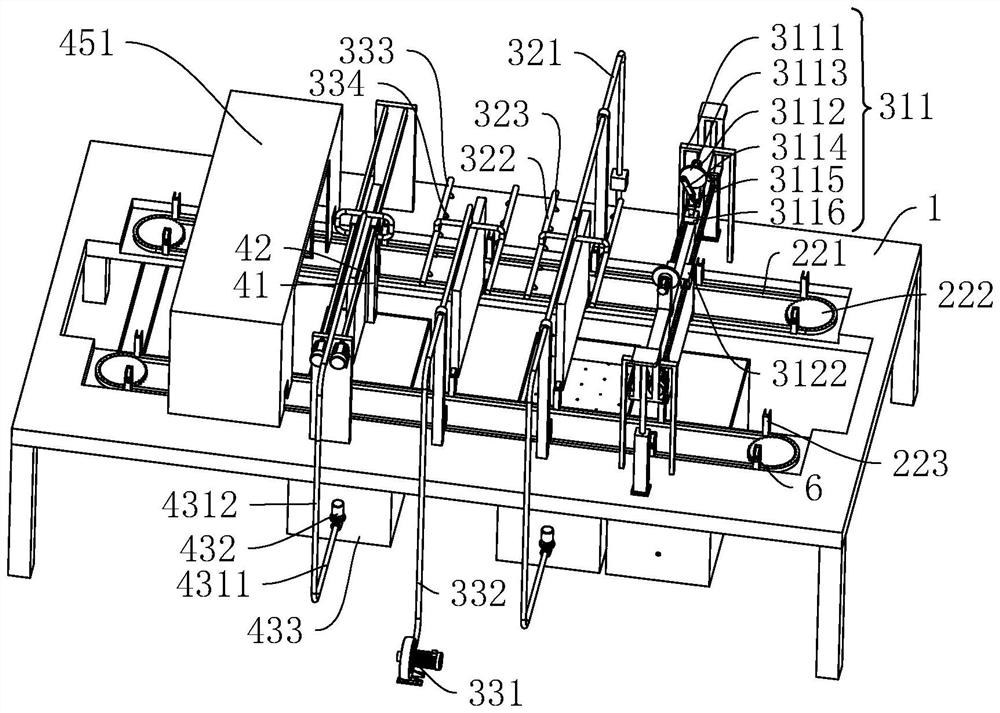

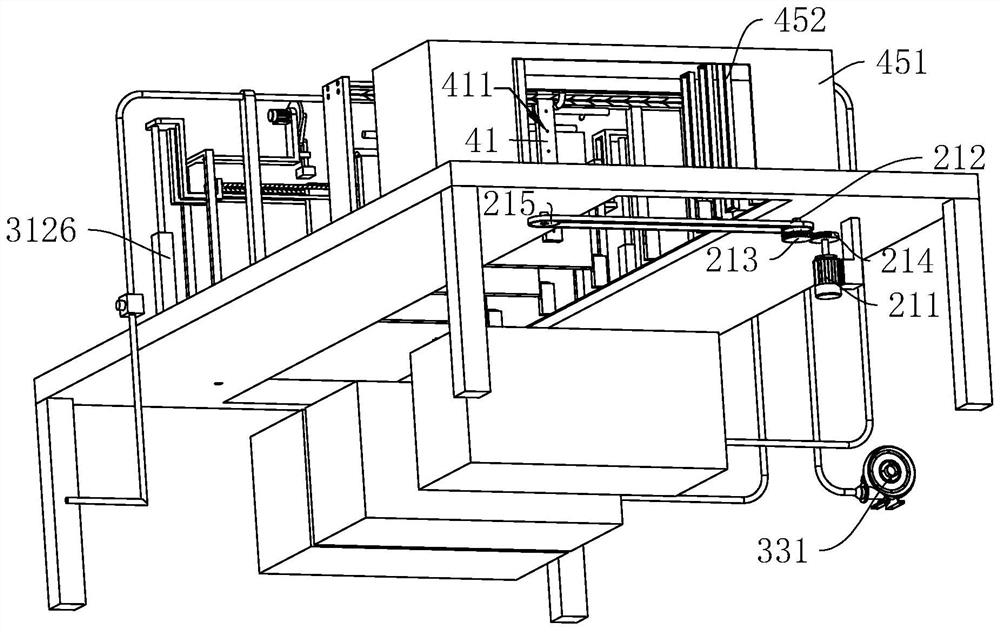

[0039] The following is attached Figure 1-3 The present invention is described in further detail.

[0040] The embodiment of the invention discloses a mold-retaining agent coating production line for aluminum templates. refer to figure 1 , the production line for mold-retaining agent coating for aluminum templates includes a workbench 1, a transport device 2, a cleaning device 3 and two sets of brushing devices 4. The setting of the device 2 facilitates the transportation of the aluminum formwork and reduces labor costs; the cleaning device 3 facilitates the cleaning of the materials on the aluminum formwork, thereby facilitating the application of mold-resisting agent to the aluminum formwork, and the setting of the brushing device 4 facilitates the cleaning of the aluminum formwork. The mold-retaining agent is evenly painted on the aluminum template to improve the brushing quality of the mold-retaining agent. The two groups of brushing devices 4 in this embodiment are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com