Food brushing device

A food and material brushing technology, which is applied in food coating, food forming, food science, etc., can solve the problems that are difficult to avoid human hands and food, reduce food hygiene safety, and reduce food production efficiency, so as to improve hygiene The effects of safety, labor saving and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

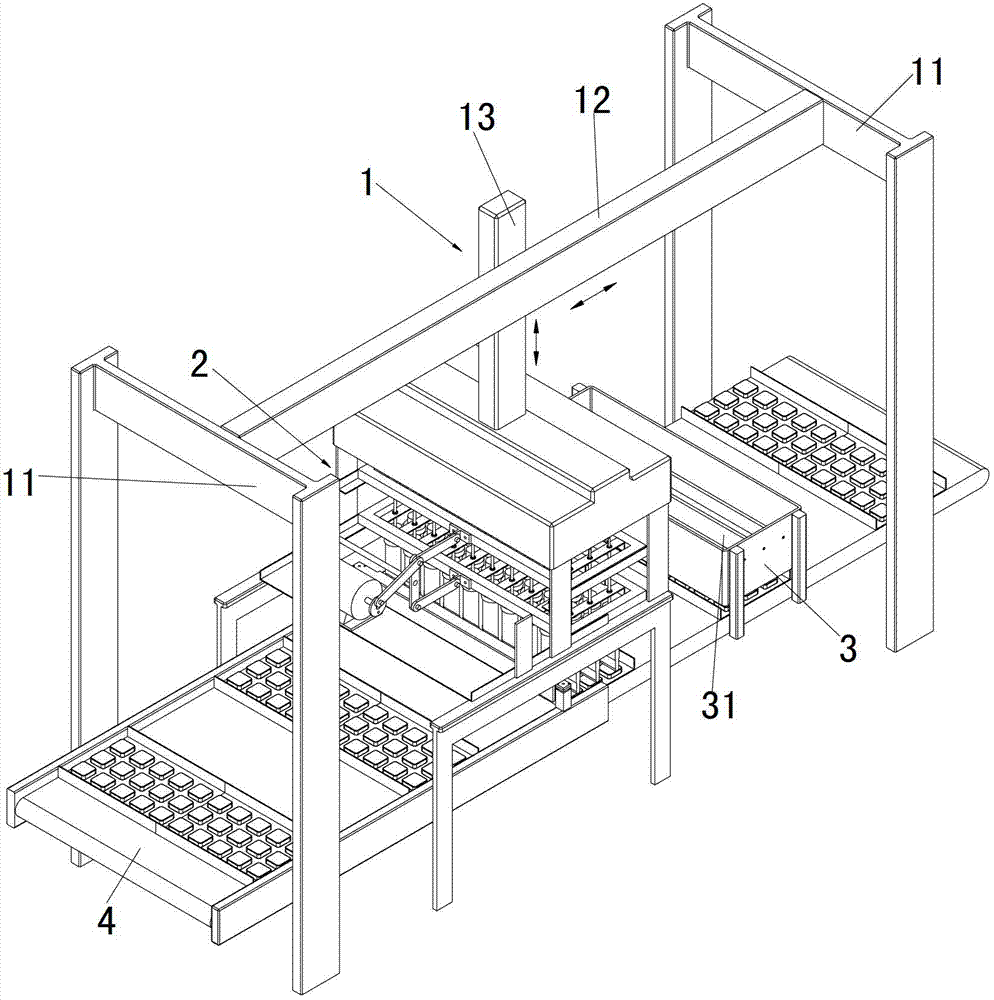

[0030] Such as figure 1 , 2 , 3, 4, and 5 show a food brushing device of the present invention, which includes a conveyor belt 4, a liquid trough 3, a brush rack 2 and a transmission mechanism 1, and the conveyor belt 4 is used to drive the food for pre-brushing Moving along its length direction, the liquid material tank 3 is used to hold liquid materials (such as oil, etc.), and the transmission mechanism 1 drives the brush material rack 2 to move.

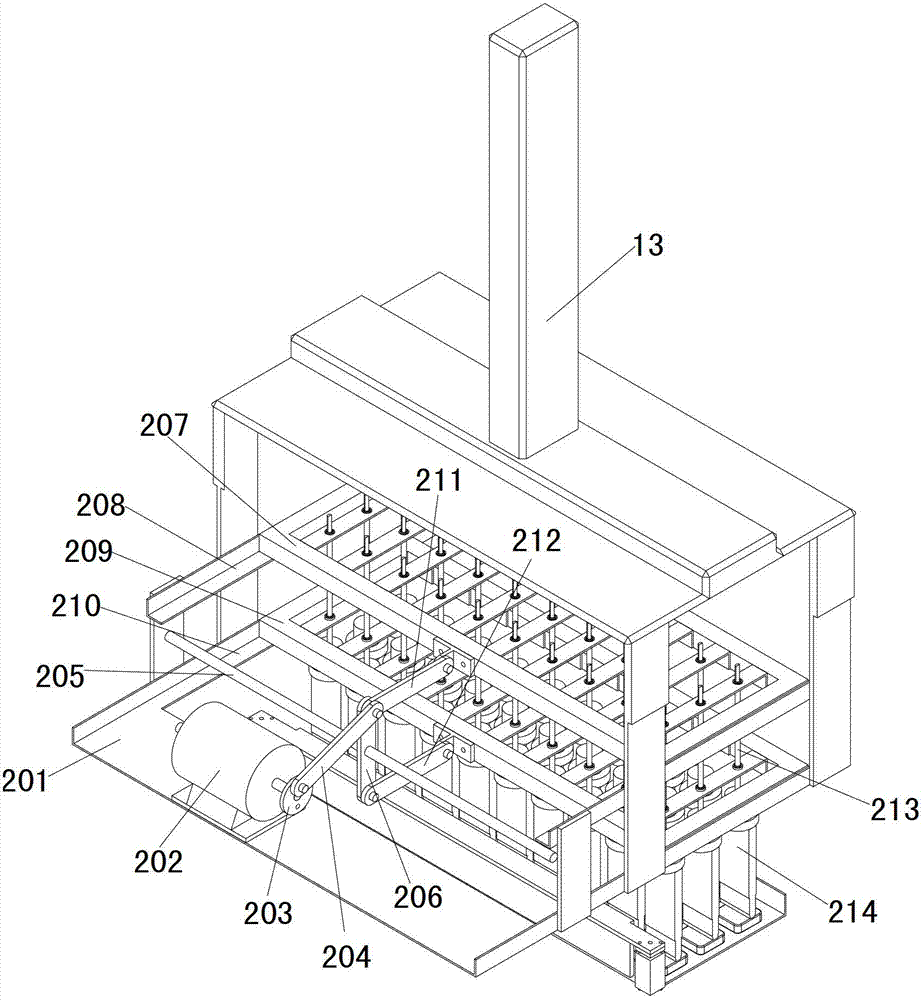

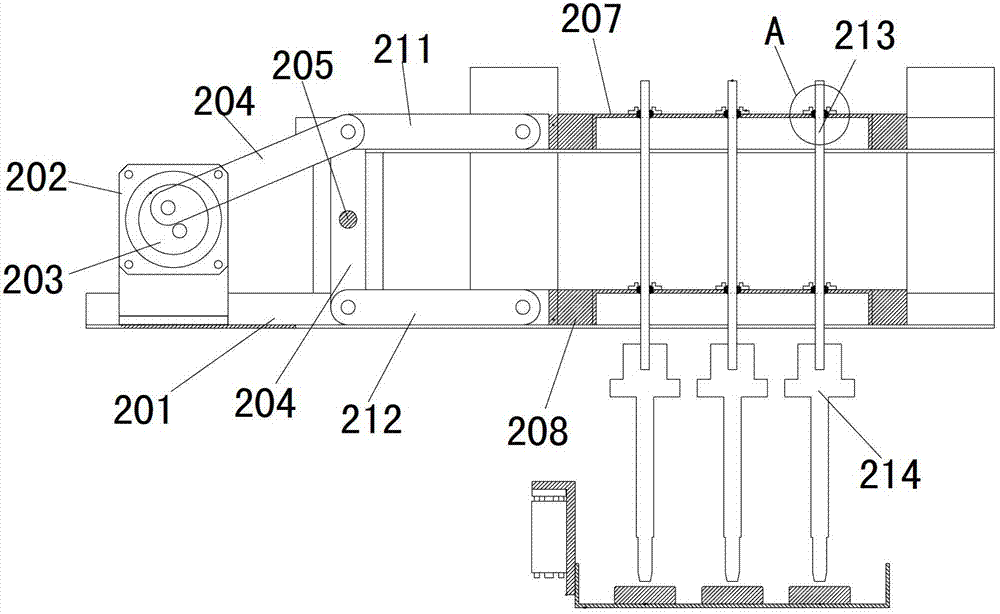

[0031] Above-mentioned material brush rack 2 comprises support 201, motor 202, eccentric wheel 203, driving link 204, lever 206, upper swing frame 207, lower swing frame 209, swing bar 213 and hairbrush 214, wherein, support 201 is fixed on the transmission The free end of mechanism 1, the body part of motor 202 is fixed on the support 201, and the extension direction of this motor 202 rotating shaft is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com