Automatic spraying production line for titanium alloy thermal forming protective coating and spraying technology

A protective coating, automatic spraying technology, applied in the coating, spray booth, spray device and other directions, can solve the problem of not adapting to the actual process requirements of titanium alloy sheet, increase procurement, maintenance costs, difficult to guarantee work efficiency, etc. Eliminate hidden dangers to personal health and safety, achieve online drying and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

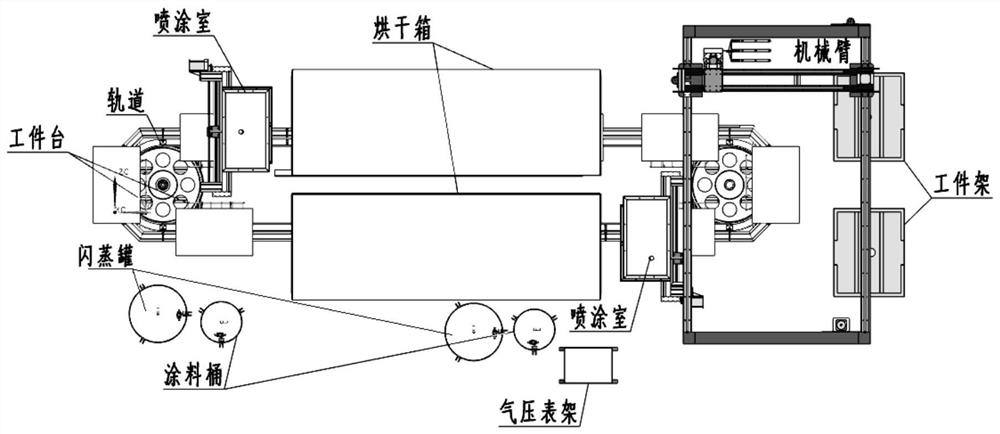

[0018] An automatic spraying production line for titanium alloy thermoforming protective coating, characterized in that: the automatic spraying production line for titanium alloy thermoforming protective coating is specifically divided into seven functional modules: control system, circular assembly line, two spraying rooms, Paint supply system, workpiece loading / unloading and turning combined station, hot air drying system, exhaust system;

[0019] Circular assembly line: the circular assembly line is used to carry the workpiece and complete each process flow; its structure includes a circular track, a workpiece carrying platform, and a track drive system; the workpiece loading / unloading and flipping combination station: its function is to realize the automatic entry / exit of the workpiece in the ring assembly line; the second is to enable the parts to be turned over to achieve the purpose of double-sided spraying; the structure includes a 12-station workpiece rack, a mechanical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com