Conveying anti-skid equipment for tablet manufacturing and packaging

A non-slip technology for packaging, applied in the direction of packaging, transportation and packaging, and slideways, etc., can solve the problems of drug damage, waste of human resources, drug collision and slipping, etc., to reduce the moving speed, prevent slip damage, increase The effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

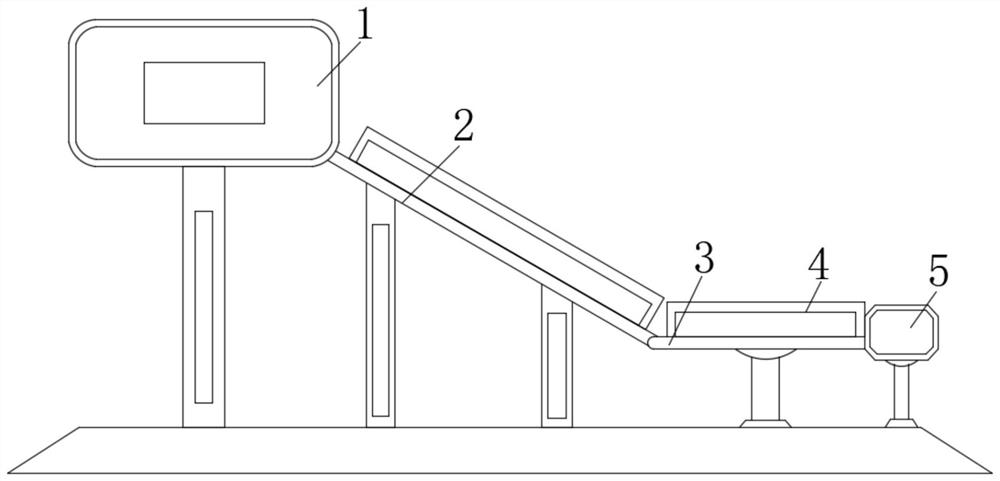

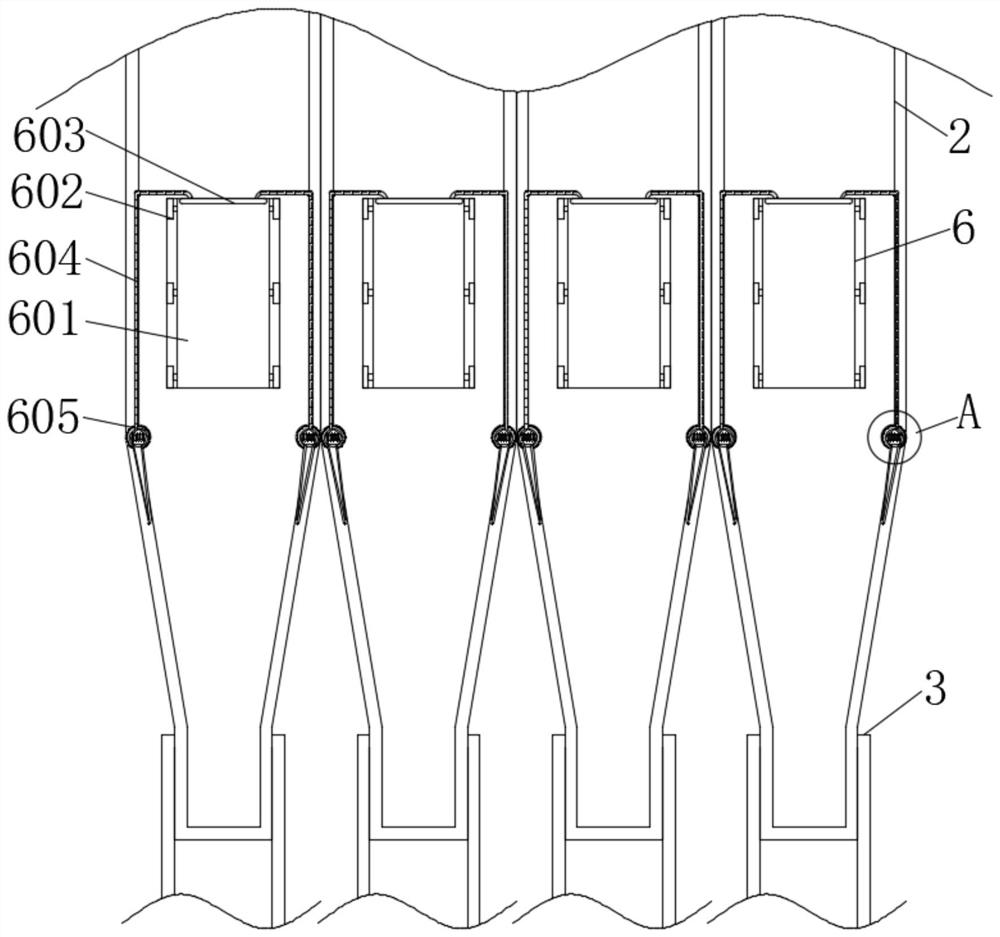

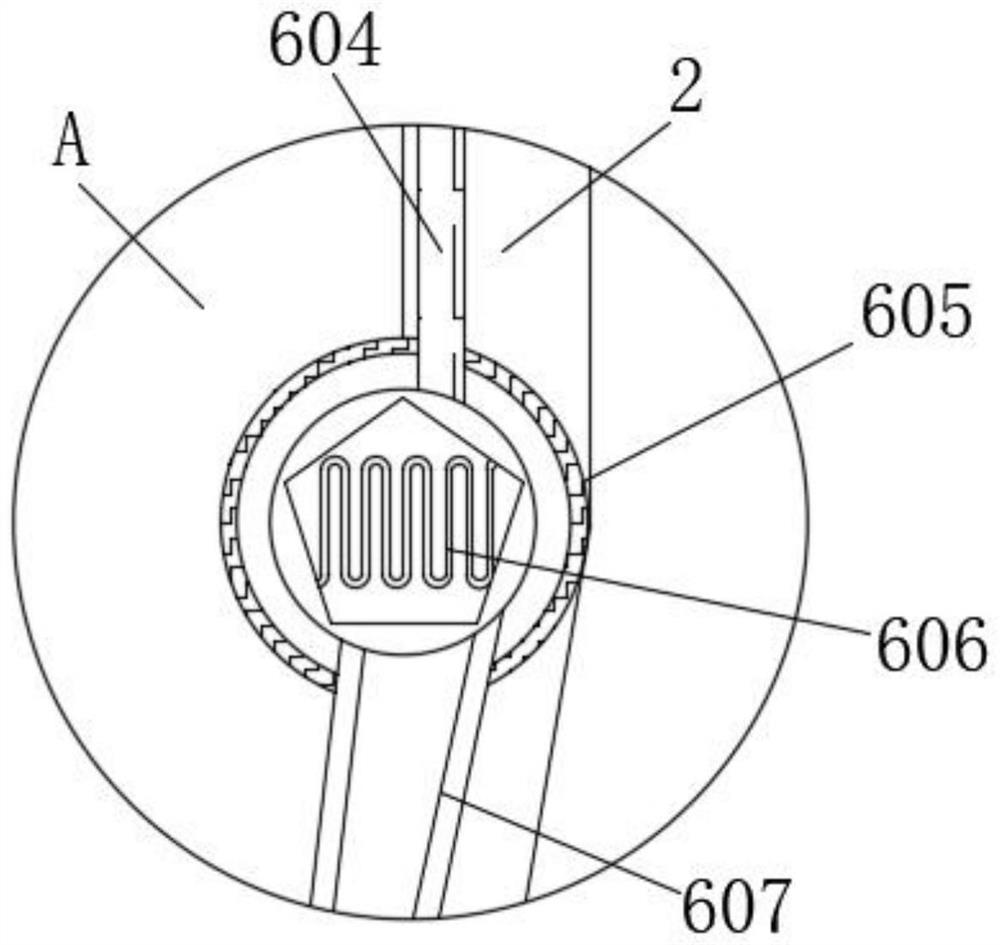

[0026] see Figure 1-4 , a kind of conveying anti-slip equipment for making and packaging tablets, comprising a production table 1, a conveying plate 2 is fixedly installed on the right side of the production table 1, a conveyor belt 3 is fixedly installed on the right side of the conveying plate 2, and the left and right sides of the conveyor belt 3 are fixedly installed There is a side plate 4, a packing mechanism 5 is fixedly installed on the right side of the conveyor belt 3, a deceleration mechanism 6 is fixedly installed in the middle of the conveying plate 2, the deceleration mechanism 6 includes a rubber belt 601, and a torsion shaft 602 is installed movable inside the rubber belt 601, and the rubber belt The left side of the top of 601 is fixedly equipped with a bump 603, the bottom of the bump 603 is fixedly connected with a connecting rope 604, and the rubber belt 601 is fixedly installed with the middle part of the top of the conveying plate 2, and the conveying pla...

Embodiment 2

[0030] see figure 1 , Figure 5 , Image 6 , Figure 7 , a kind of conveying anti-slip equipment for making and packaging tablets, comprising a production table 1, a conveying plate 2 is fixedly installed on the right side of the production table 1, a conveyor belt 3 is fixedly installed on the right side of the conveying plate 2, and the left and right sides of the conveyor belt 3 are fixedly installed There is a side plate 4, a packing mechanism 5 is fixedly installed on the right side of the conveyor belt 3, a deceleration mechanism 6 is fixedly installed in the middle of the conveying plate 2, a quantitative wheel 7 is detachably installed on the right side of the side plate 4, and the middle part of the inner cavity of the quantitative wheel 7 A positioning rod 701 is movable, and the top of the positioning rod 701 is fixedly equipped with a vertical rod 702. The left side of the vertical rod 702 top is provided with a groove 703, and the inner cavity of the groove 703 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com