Labyrinth seal structure based on high-speed centrifugal machine and mounting method

A high-speed centrifuge and labyrinth seal technology, which is used in the sealing of engines, supporting machines, mechanical equipment, etc., can solve the problems of reducing the vibration detection accuracy of the high-speed shaft, the failure of the high-speed shaft and the labyrinth, and inconvenient to clean the labyrinth seal fluid. Achieve the effect of reducing the risk of damage, strong sealing effect and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] Example: Please refer to Figures 1 through 15 :

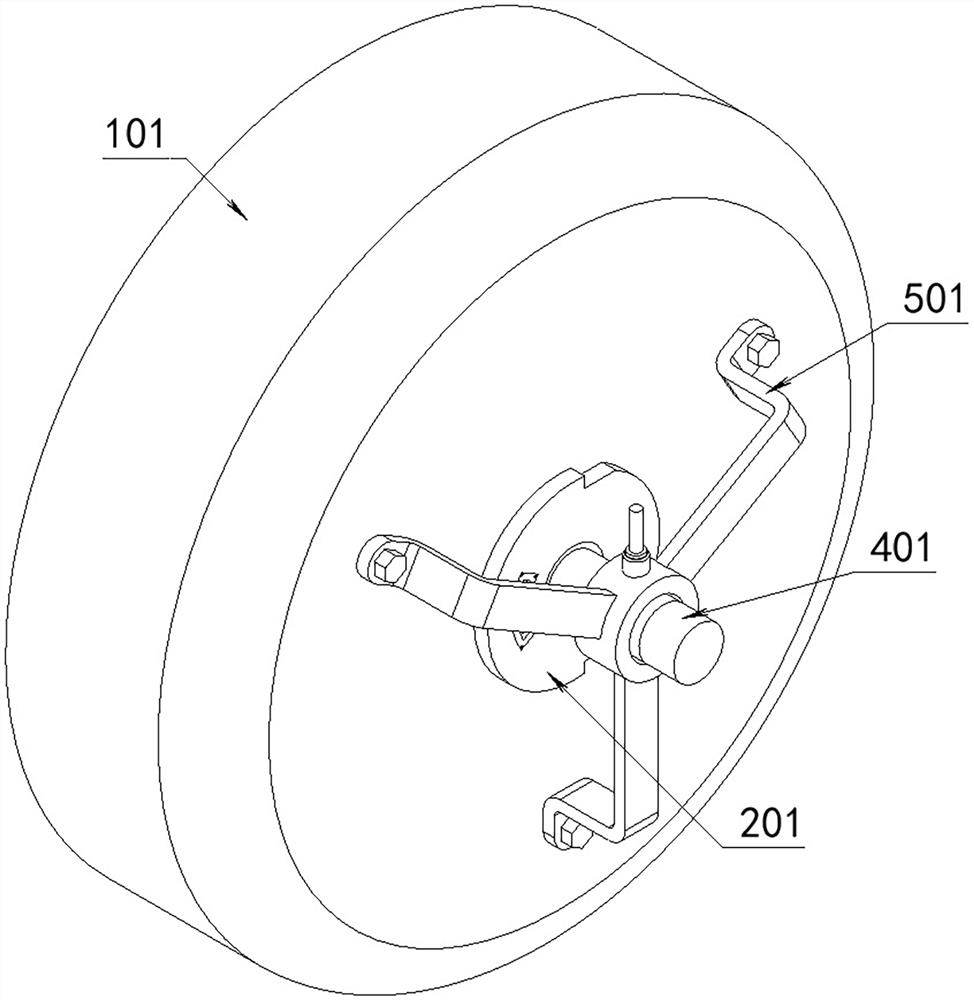

[0045] The present invention proposes a labyrinth sealing structure and installation method based on a high-speed centrifuge, comprising the main body 1; the right side of the body 1 is installed with a sealing component 2, and the interior of the sealing assembly 2 is installed with a cleaning component 3; the drive mechanism 4, the drive mechanism 4 is installed inside the sealing assembly 2, and the right side of the body 1 is installed with a detection mechanism 5.

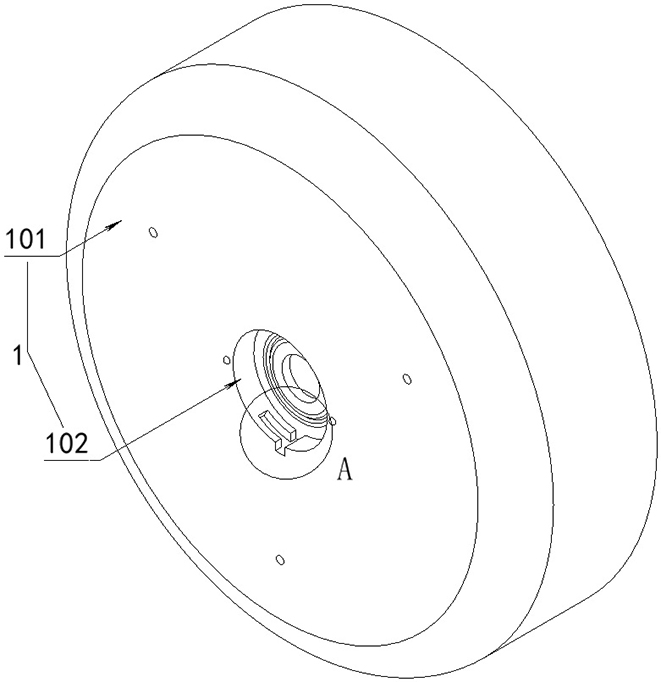

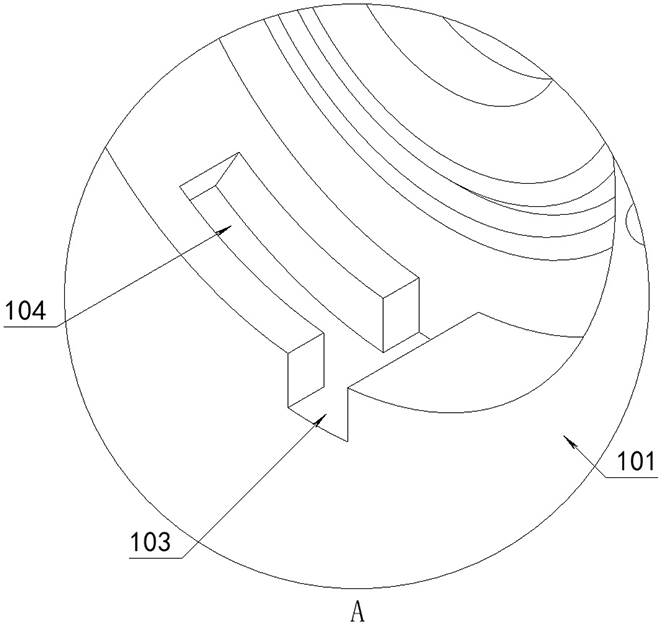

[0046] Further, according to embodiments of the present invention, such as Figures 2 through 10 As shown, the main body 1 comprises: centrifuge housing 101, centrifuge housing 101 as a whole is a cylindrical structure; mounting groove 102, mounting groove 102 is set on the right side of the centrifuge housing 101; guide groove 103, guide groove 103 is disposed on the centrifuge housing 101; chute 104, chute 104 is disposed on the centrifuge housing 101; seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com