Self-tightening clamp for V-shaped notch shear test of composite material and test method

A composite material, shear test technology, applied in the direction of using stable shear force to test material strength, using stable tension/pressure to test material strength, analyzing materials, etc., can solve the time-consuming and laborious installation, axis and load line Unable to overlap, small working area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

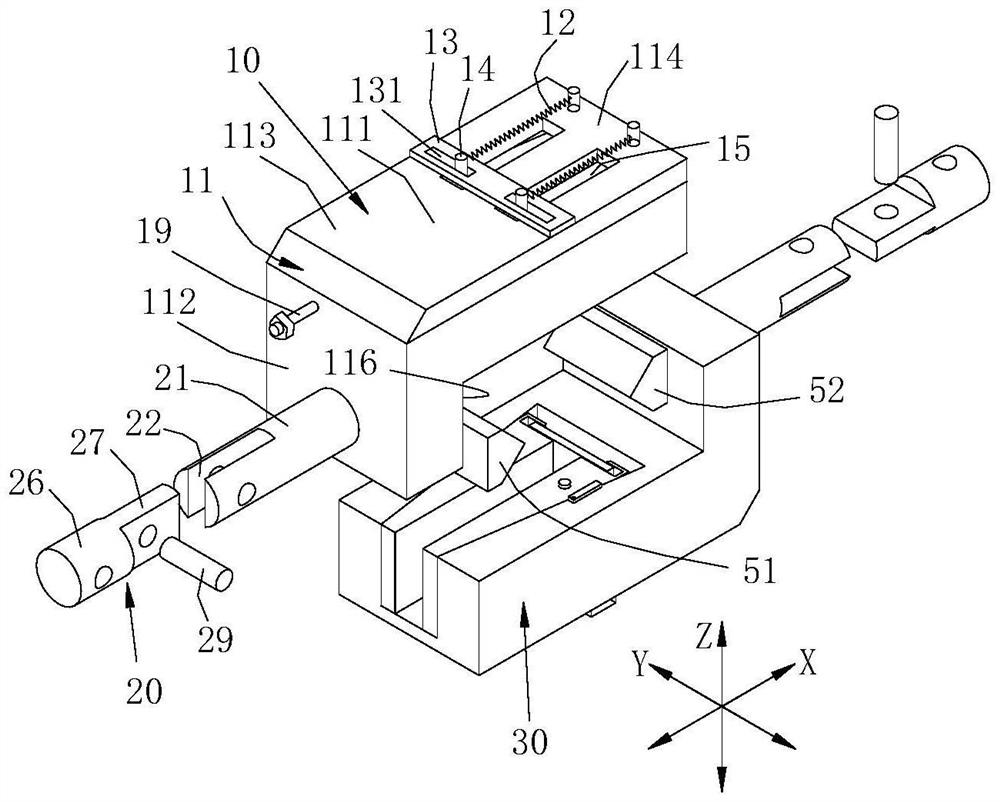

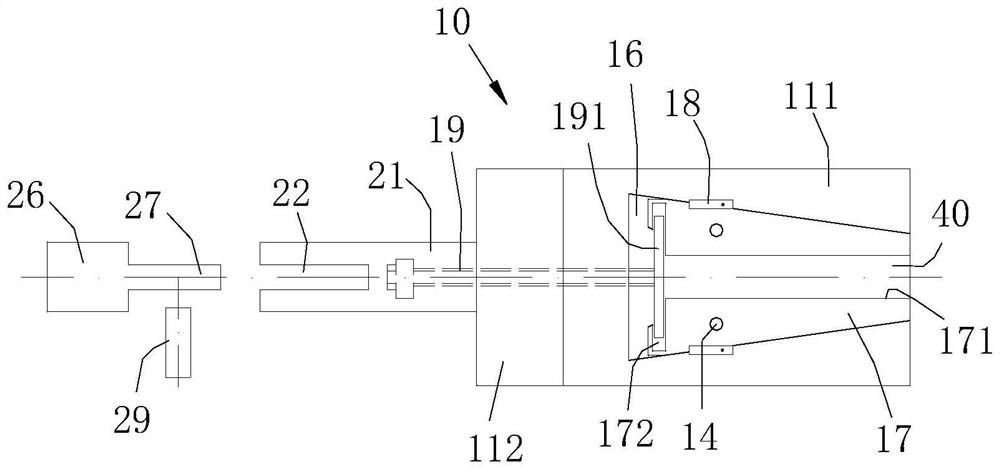

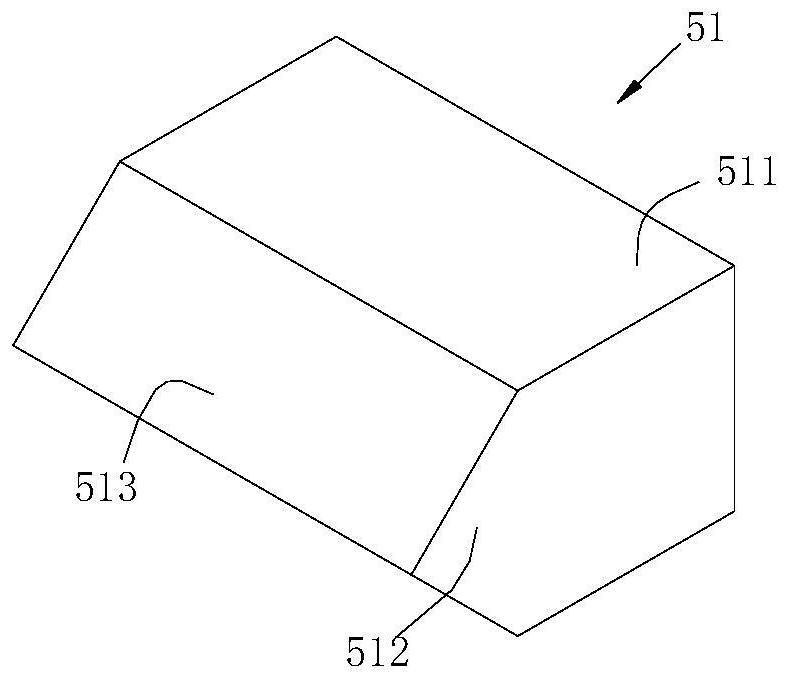

[0050] refer to figure 1 with figure 2 , in the drawings, the orientation of the first axis X indicates the direction of the first axis, the orientation of the second axis Y indicates the direction of the second axis, and the orientation of the third axis Z indicates the direction of the third axis.

[0051] A self-tightening clamp for V-notch shear test of composite materials, which includes two opposite clamping pieces, the two clamping pieces are respectively a first clamping piece 10 and a second clamping piece 30 . The first clamping part 10 and the second clamping part 30 have the same structure.

[0052] Wherein the first clamping member includes an L-shaped body 11, the body 11 includes a clamping portion 111 and a stretching portion 112 connected together, wherein the clamping portion 111 extends along the first axis, and the stretching portion 112 extends along the first axis. The second axis extends in the direction of the second axis, and the first axis is perpe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com