Adjustable sleeve type periodic vibration reduction structure and manufacturing method thereof

A vibration-damping structure and sleeve-type technology, applied in special data processing applications, geometric CAD, CAD numerical modeling, etc., can solve the failure of periodic wave barriers, it is difficult to change the working frequency band, and cannot meet the vibration reduction requirements of different frequency bands, etc. problem, achieve the effect of suppressing the transmission of vibration and meeting the requirements of vibration reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

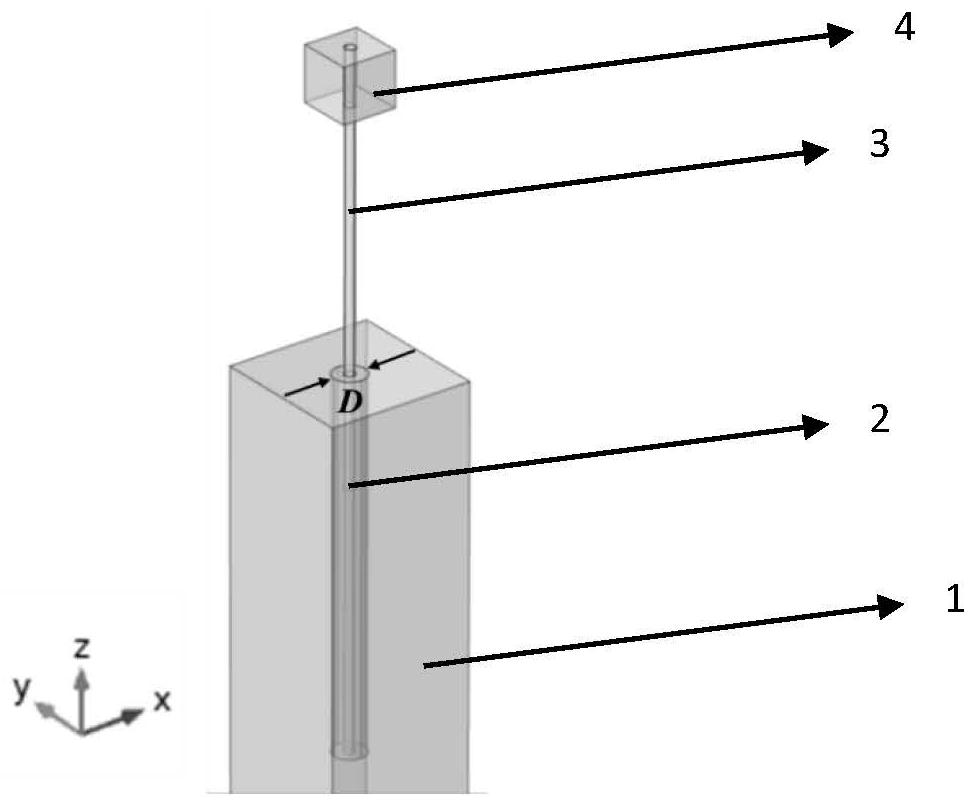

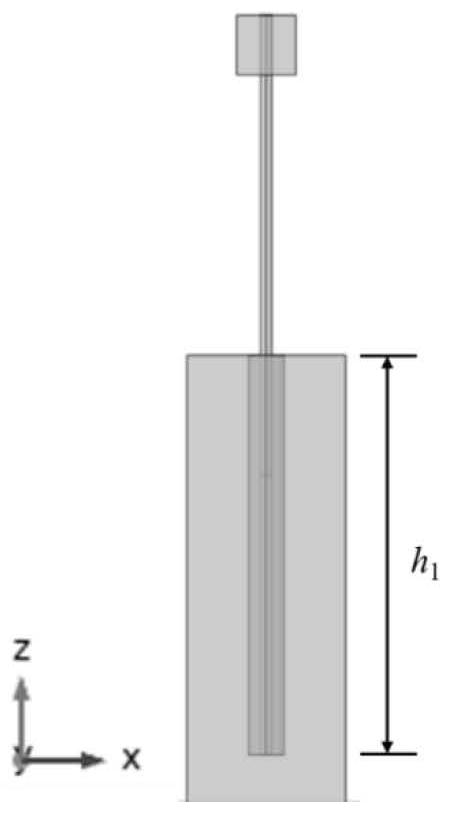

[0043] An adjustable sleeve-type periodic damping structure includes: a matrix 1 and a scatterer, wherein the soil is used as the matrix, and the scatterers are periodically distributed in the matrix in the form of equal intervals and partial embedment. The scatterer includes a sleeve 2 , a screw 3 , a top block 4 and a regulating assembly 5 .

[0044] figure 1 , figure 2 What is shown is a unit model diagram of an adjustable sleeve-type periodic vibration-damping barrier structure. In the figure, only the case where the top block is a cube is shown, and other shapes have similar vibration-damping effects. This manual will not Attached figures are given.

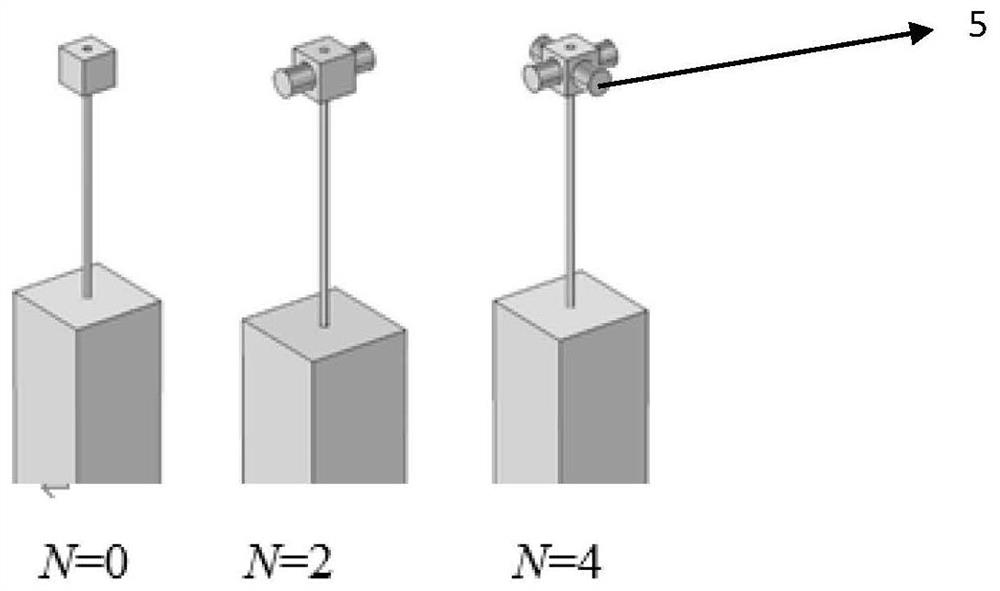

[0045] image 3 , Figure 4 is a quality adjustment model, including two cases of symmetrical arrangement and asymmetrical arrangement. The symmetrical arrangement includes the three cases where the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com