RFID-based intelligent storage material detection system and method

A technology of intelligent warehousing and detection system, applied in the field of warehousing management, can solve the problem of low efficiency of manual checking of goods positioning, and achieve the effect of improving the efficiency of warehousing operations, ensuring accurate input, and avoiding manual misregistration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

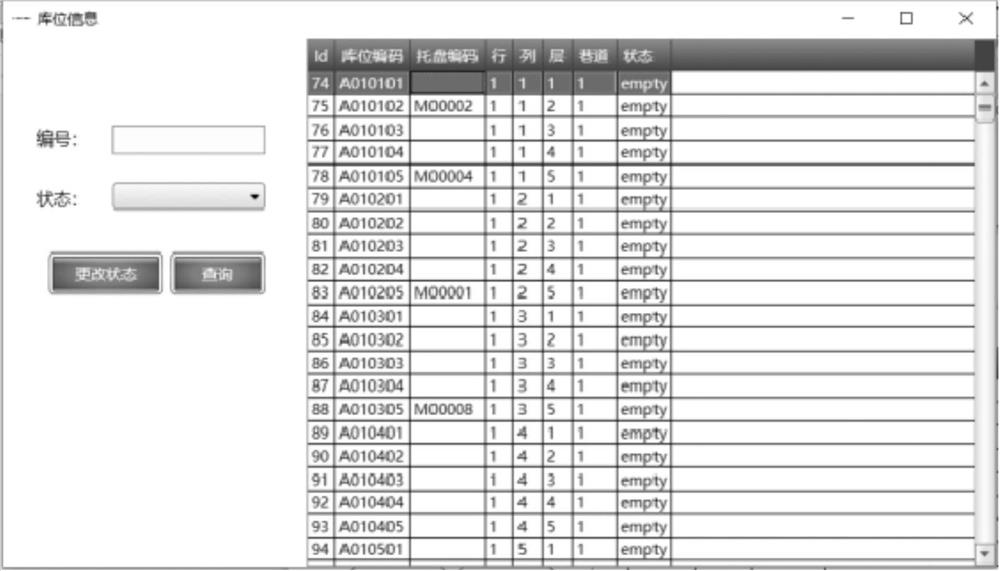

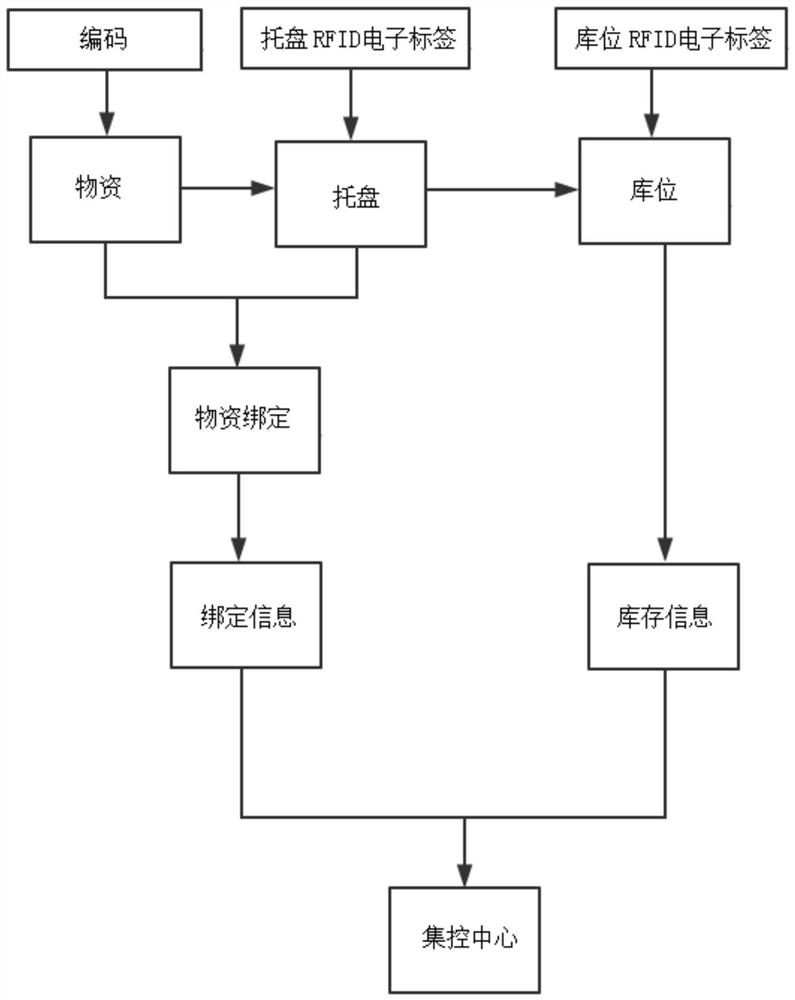

[0024] combine Figure 1 to Figure 5 , the RFID-based intelligent storage material detection system provided in this embodiment, the intelligent storage is divided into horizontal storage area, handover area, three-dimensional storage area and centralized control center, horizontal storage area, transfer area and three-dimensional storage area are equipped with Storage space, electric forklifts, jacking stations, cranes and stackers are also installed in the intelligent storage. There are RFID handheld devices and pallets, RFID handheld devices are used to read the codes on the materials, pallet label brackets are provided on the pallets, and pallet RFID electronic tags are embedded in the pallet label brackets; the flat storage area, transfer area and three-dimensional The warehouse positions in the warehouse area are equipped with RFID electronic tags; the electric f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com